Preparation method of graphene with nano ferroferric oxide precipitated on surface

A technology of graphene and graphite, which is applied in the field of materials, can solve the problems of graphene specific surface area reduction, affect the excellent performance of graphene, destroy graphene, etc., and achieve the effect of not being easy to agglomerate, simple and easy to prepare, and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

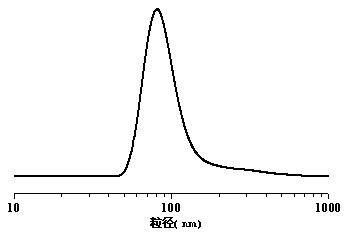

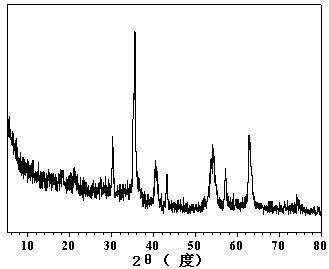

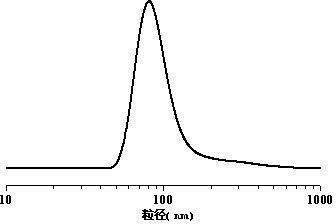

Image

Examples

Embodiment 1

[0026] (1) Preparation of graphite oxide

[0027] Weigh 2g of natural flake graphite and 1g of sodium nitrate, mix well; add concentrated H 2 SO 4 50ml, stirred under ice bath conditions, slowly added the mixture of graphite and sodium nitrate, slowly added 6g KMnO 4 , strictly control the temperature below 10°C, last about 0.5h, keep the temperature and continue to react for 2h; heat to 30°C, react for 3h, continue to slowly increase the temperature to 98°C, and slowly add H 2 O 100ml, keep the reaction at 100°C for about 2 hours, observe the color change; dilute the system with warm water, H 2 O dosage is about 150ml, add 15ml H 2 o 2 ; After the reaction, add a large amount of deionized water to dilute the product, and use 5% dilute hydrochloric acid to wash until the barium chloride solution cannot detect SO 4 2- Until then, it was repeatedly washed with deionized water until the pH value was neutral, and finally filtered and dried to obtain graphite oxide.

[0028...

Embodiment 2

[0033] (1) Preparation of graphite oxide

[0034] Add 30ml of concentrated sulfuric acid and 10ml of concentrated nitric acid into the three-neck flask, mechanically stir in ice-water bath for 20min to obtain mixed acid, take 2g of natural flake graphite and add it, after stirring for 15min, gradually add 6g of potassium chlorate powder slowly, and react for 72h. After the reaction, add a large amount of deionized water to dilute the product, wash with 5% dilute hydrochloric acid until the barium chloride solution cannot detect SO 4 2- Until then, it was repeatedly washed with deionized water until the pH value was neutral, and dried by suction to obtain graphite oxide.

[0035] (2) Graphene is prepared by reducing graphene oxide with zinc powder

[0036] Weigh graphite oxide 0.2g and H 2 O mixed with ultrasonic stripping to obtain 400ml of a suspension with a concentration of 0.5mg / ml, stirred evenly, added 1g of zinc powder, and ultrasonically reacted for 3h. After the re...

Embodiment 3

[0040] (1) Preparation of graphite oxide

[0041] Weigh 2g of natural flake graphite and 1g of sodium nitrate, mix well; add concentrated H 2 SO 4 50ml, stirred under ice bath, slowly added the mixture of graphite and sodium nitrate, slowly added 6g KMnO 4 , control the temperature below 10°C for about 2 hours, keep the temperature and continue the reaction for 5 hours; heat to 50°C in a water bath for 4 hours; continue to slowly raise the temperature to 90°C, and slowly add H 2 O 100ml, strictly control the temperature at 100°C, keep the reaction for about 5 hours, observe the color change; dilute the system with warm water, H 2 The amount of O is about 150ml, add 15ml of H 2 o 2 ; After the reaction, add a large amount of deionized water to dilute the product, and use 5% dilute hydrochloric acid to wash until the barium chloride solution cannot detect SO 4 2- Until then, it was repeatedly washed with deionized water until the pH value was neutral, and finally filtered...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com