A method for preparing normal and low temperature zno/sms composite gas desulfurization material

A normal low temperature, coal gas technology, applied in the field of preparation of coal gas desulfurization materials, can solve the problems of zinc oxide desulfurization agent porosity, active component utilization rate reaction and low mass transfer efficiency, etc., to achieve gas-solid reaction rate and mass transfer efficiency, improving desulfurization efficiency, and improving chemical reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

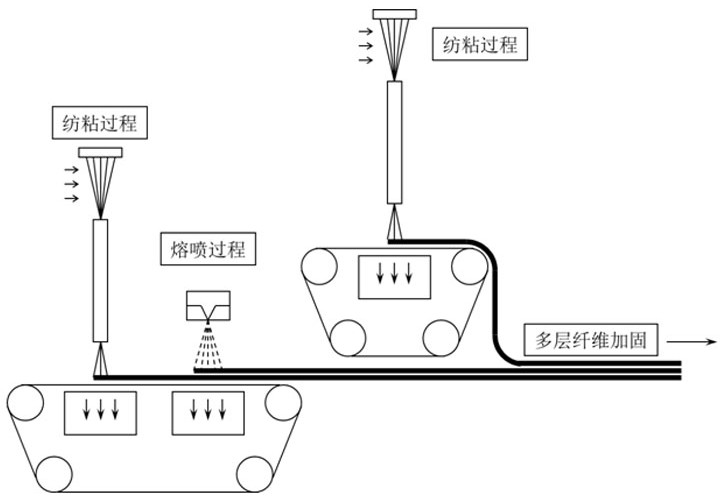

Embodiment 1

[0019] Mix 1 g of the active component ZnO precursor zinc acetate powder with 0.67 g of polyacrylonitrile (PAN) powder to obtain a mixture powder; use a spunbond spinning device for the mixture powder and use a general method in the field to prepare ZnO / SMS normal and low temperature gas The upper and lower layers of the desulfurization agent are spunbonded spinning materials (not to be explained too much here). The spunbond spinning process was carried out under the parameters of melt temperature setting 150 °C, side blowing temperature 15 °C, and spunbond fiber receiving distance 5 cm; the mixture powder was prepared by using a melt-blown spinning device and using a general method in the field to prepare ZnO / The middle layer melt-blown spinning material of SMS normal and low temperature gas desulfurizer. The melt blown spinning process is carried out under the parameters of melt blown process temperature of 120 °C, side blowing temperature of 15 °C, and melt blown receiving...

Embodiment 2

[0026] Mix 1 g of the active component ZnO precursor zinc acetate powder with 1.44 g of polyacrylonitrile (PAN) powder to obtain a mixture powder; use a spunbond spinning device for the mixture powder and use a general method in the field to prepare ZnO / SMS normal and low temperature gas The upper and lower layers of the desulfurization agent are spunbonded spinning materials (not to be explained too much here). The spunbond spinning process is carried out under the conditions that the melt temperature is set at 170°C, the side blowing temperature is 18°C, and the spunbond fiber receiving distance is 12cm; the mixture powder is prepared by using a meltblown spinning device and using a general method in the field to prepare ZnO / SMS The middle layer melt blown spinning material of normal and low temperature gas desulfurizer. The parameters of the melt-blown spinning process are the melt temperature of 145°C during the melt-blown process, the side blowing temperature of 18°C, and...

Embodiment 3

[0030] Mix 1 g of the active component ZnO precursor zinc acetate powder with 2.69 g of polyacrylonitrile (PAN) powder to obtain a mixture powder; use a spunbond spinning device for the mixture powder and use a general method in the field to prepare ZnO / SMS normal and low temperature gas The upper and lower layers of the desulfurization agent are spunbonded spinning materials (not to be explained too much here). The spunbond spinning process is carried out under the conditions that the melt temperature is set at 190°C, the side blowing temperature is 20°C, and the spunbond fiber receiving distance is 17cm; the mixture powder is prepared by using a meltblown spinning device and using a general method in the field to prepare ZnO / SMS The middle layer melt blown spinning material of normal and low temperature gas desulfurizer. The parameters of the melt-blown spinning process are the melt temperature of 170 °C during the melt-blown process, the side blowing temperature of 20 °C, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com