A poss modified high toughness solid buoyancy material and preparation method thereof

A technology of solid buoyancy and high toughness, applied in the field of solid buoyancy materials, it can solve the problem that buoyant materials cannot be uniformly dispersed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A preparation method of a POSS-modified high-toughness solid buoyancy material, comprising the steps of:

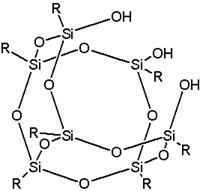

[0036] (1) Dissolve a certain amount of POSS for surface modification of hollow glass microspheres in ethanol solution, then add an appropriate amount of hollow glass microspheres into the solution, mechanically stir at 20rpm / min at 50°C for 1h and ultrasonically disperse After 10 minutes, vacuum filter, dry, and sieve to obtain POSS surface-modified hollow glass microspheres, which are set aside.

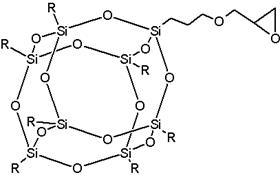

[0037] (2) After dissolving a certain amount of POSS for epoxy resin modification with tetrahydrofuran, add it to the epoxy resin, and mechanically stir at 10rpm / min at 80°C for 4h. After the tetrahydrofuran solvent is completely volatilized, POSS modified Epoxy resin matrix, spare.

[0038] (3) Add the curing agent and accelerator to the POSS-modified epoxy resin matrix prepared in step (2), and after mixing evenly, add the POSS surface-modified hollow glass microsphe...

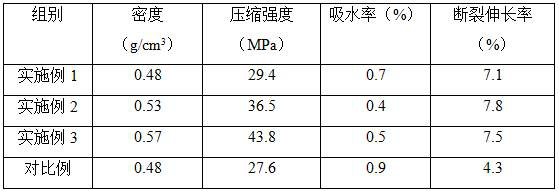

Embodiment 1

[0043] According to the mass percentage, get 100 parts of bisphenol A type epoxy resin E44, modify with 10 parts of epoxy resin modified heptaisooctyl single epoxy group POSS according to the above method; get 30 parts of S15 hollow glass of 3M company The microspheres were modified with 10 parts of heptaisooctyltrisilyloxy POSS for surface modification of hollow glass microspheres. The POSS modified epoxy resin matrix made and the hollow glass microspheres of POSS surface modification, mix 90 parts of methyltetrahydrophthalic anhydride MeTHPA, 0.5 part of 2-ethyl-4-methyl Imidazole, made of POSS-modified high-toughness solid buoyancy material products.

Embodiment 2

[0045] According to the mass percentage, get 100 parts of bisphenol A type epoxy resin E51, modify with 10 parts of epoxy resin modified heptaisobutyl monoepoxy group POSS according to the above method; get 35 parts of K20 hollow glass of 3M company The microspheres were modified with 10 parts of heptaisooctyltrisilyloxy POSS for surface modification of hollow glass microspheres. The prepared POSS modified epoxy resin matrix and POSS surface modified hollow glass microspheres were mixed with 23 parts of isophorone diamine IPDA and 0.2 part of DMP-30 according to the above method to make POSS modified high Product of ductile solid buoyancy material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com