Method for complexly refining aluminum alloy solidified structure by using current and crystal grain refining agent

A technology of grain refiner and solidification structure, which is applied in the refinement process of aluminum alloy solidification structure, to achieve the effects of novel ideas, increased nucleation rate, and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

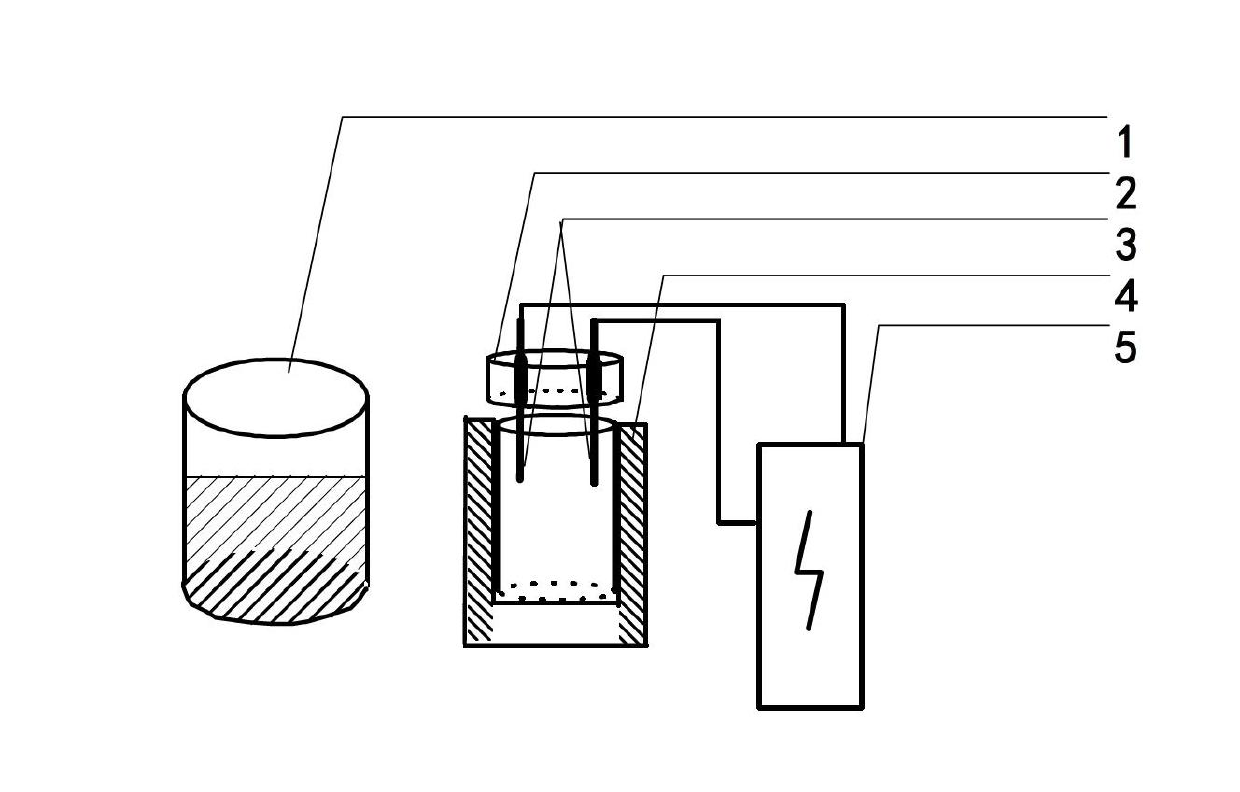

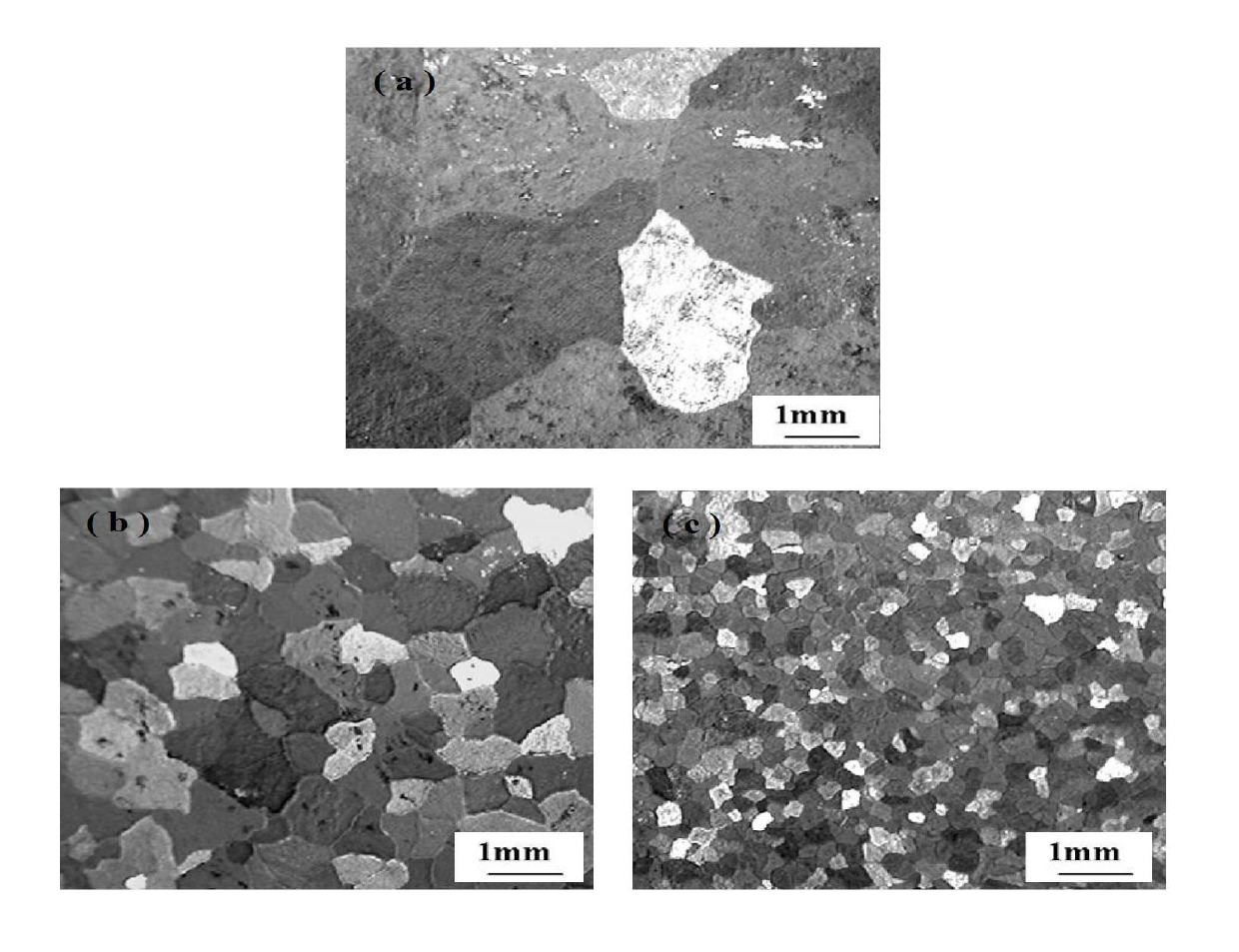

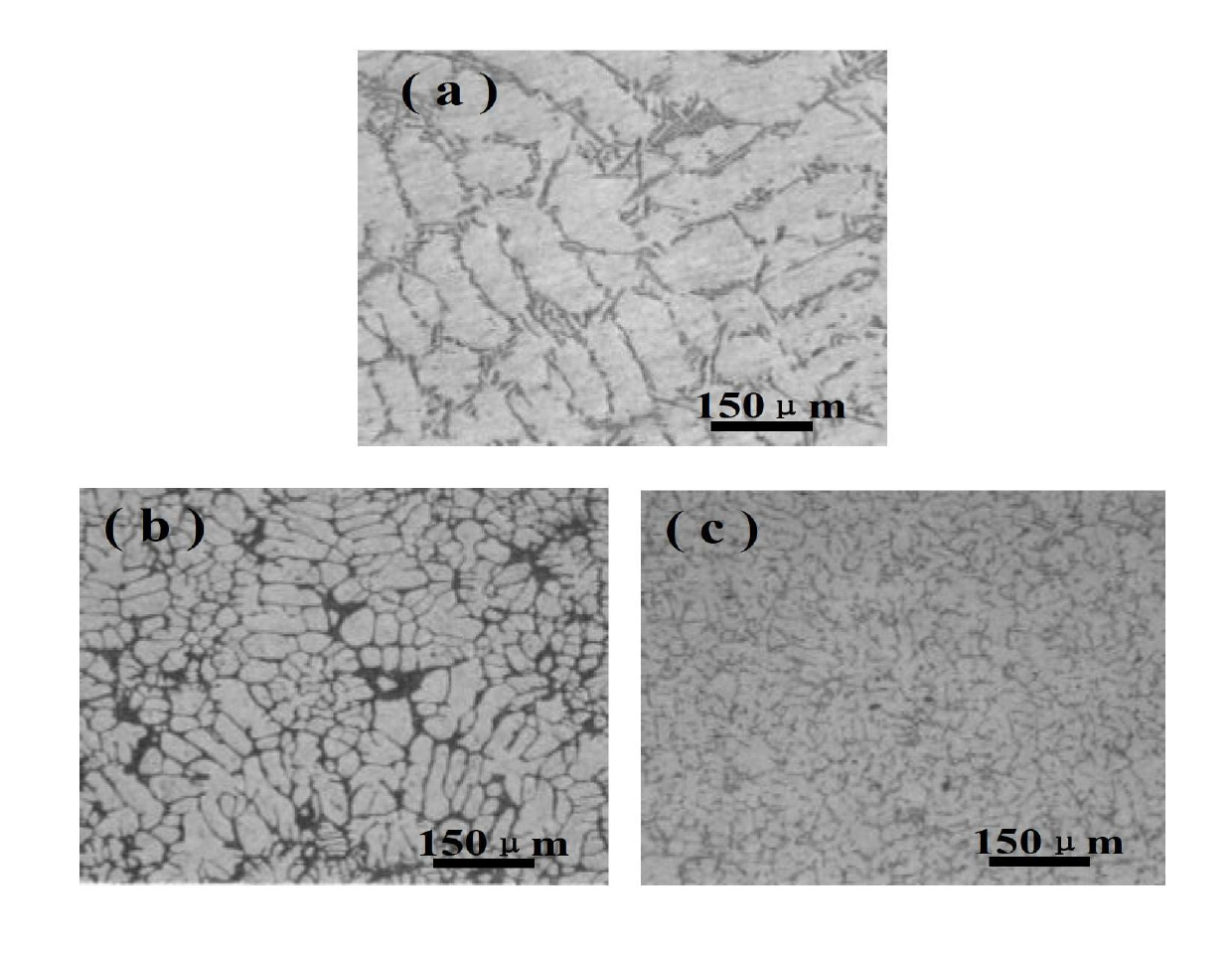

Embodiment 1

[0038] The alloy uses commercial pure aluminum ingots (99.7%), the grain refiner adopts the domestic aluminum alloy refiner with the composition of Al-5Ti-0.25C provided by Shandong Shanda Lumei Melt Technology Co., Ltd., and uses a 7.5Kw graphite crucible resistor Furnace for melting and metal mold Φ70×100mm for casting. All molds are installed with the same graphite electrode Φ10×100mm before casting to eliminate the influence of electrode materials and ensure the accuracy of test results. The technological process is as follows: 720°C completely melts the pure aluminum, pours after the temperature stabilizes, and obtains 1# ingot. Put the graphite melting crucible 1 containing the alloy mother liquor back into the crucible resistance furnace, and ensure that its temperature is stable at 720°C, add 0.1wt.% Al-5Ti-0.25C grain refiner, and stir for 5 minutes. Adjust the output parameter of the power supply to DC 60A, and connect it to the electrode 3 in the 3# mold. Pouring ...

Embodiment 2

[0041]A commercial A356 aluminum alloy ingot was used, and the grain refiner was Al-5Ti-B grain refiner provided by Suzhou Institute of Nonferrous Metals. Use 7.5Kw graphite crucible resistance furnace for melting and metal type Φ70×100mm mold for casting. All molds are installed with the same graphite electrode 3 of Φ10×100mm before casting to eliminate the influence of the electrode material, so as to ensure the accuracy of the test results. The process is as follows: completely melt the aluminum ingot at 740°C, blow argon to degas for 8 minutes, remove slag, and pour after the temperature stabilizes to 740°C to obtain 1# ingot. Put the graphite crucible 1 containing the alloy mother liquor back into the crucible resistance furnace, and ensure that its temperature is stable at 740°C, add 0.5wt.% Al-5Ti-B grain refiner, and stir for 5 minutes. Adjust the output parameters of the power supply to pulse peak current 100A, frequency 500Hz, duty cycle 30%, and connect to electrod...

Embodiment 3

[0044] Using ADC12 commercial aluminum alloy ingot and Al-5Ti-B grain refiner provided by Suzhou Institute of Nonferrous Metals, a 7.5Kw graphite crucible resistance furnace was used for melting and a metal mold of Φ70×100mm. All molds are installed with the same graphite electrode Φ10×100mm before casting to eliminate the influence of electrode materials. The process is as follows: completely melt the aluminum ingot at 740°C, blow argon to degas for 10 minutes, remove slag, wait for the temperature to stabilize at 730°C, add 1wt.% Al-5Ti-B grain refiner, and stir for 5 minutes. Adjust the output parameters of the power supply to AC 60A, 50Hz, and connect it to the electrode in the 2# mold. Pouring molds 1# and 2# in sequence, turning on the power output switch, maintaining the current output in mold 2# from the beginning of pouring until the alloy liquid is completely solidified, and obtaining ingots 1# and 2#.

[0045] Take the central part at 40mm from the bottom surface f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com