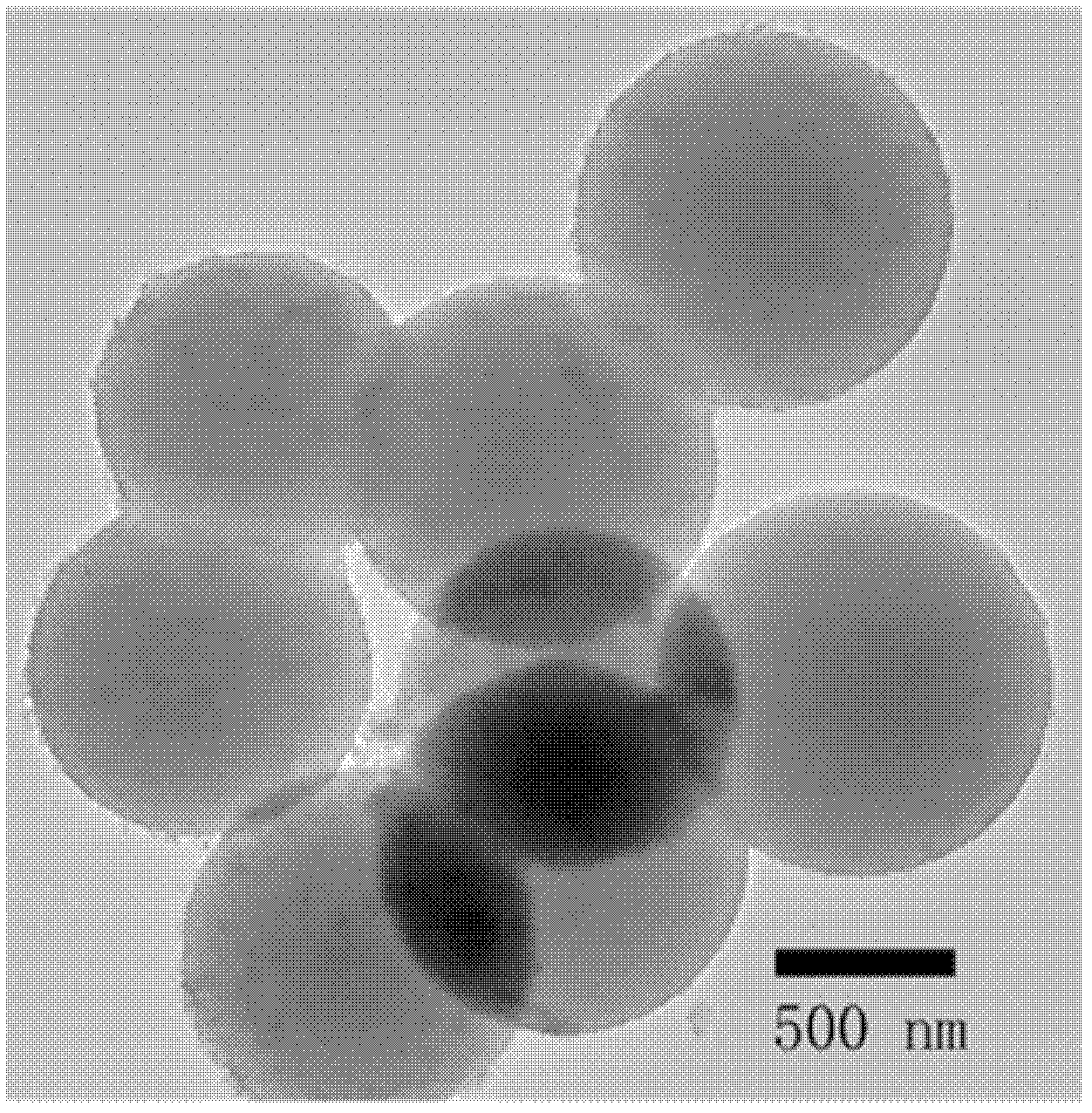

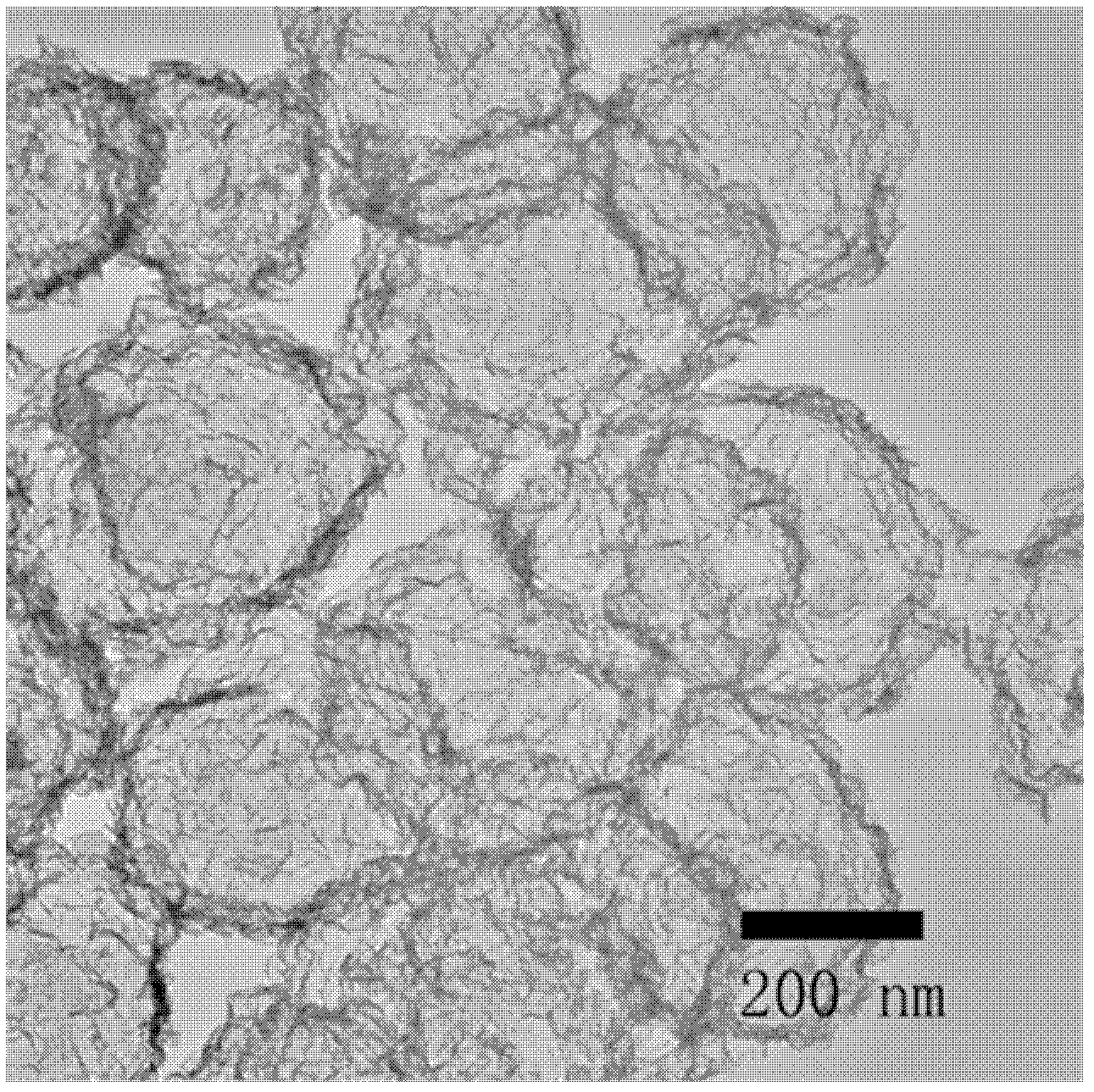

Multi-element composite metal oxide hollow nanosphere and preparation method thereof

A composite metal and oxide technology, applied in the direction of alkali metal oxide/hydroxide, alkali metal compound, metal/metal oxide/metal hydroxide catalyst, etc. Problems such as the inheritance of the composition of the hollow sphere and the pollution of the methanol solution to the environment have achieved the effects of universality, low cost, and controllable ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A. Use deionized water to prepare Ni(NO 3 ) 2 ·6H 2 O, ZnCl 2 and Al(NO 3 ) 3 9H 2 O metal salt solution in which ZnCl 2 , Ni(NO 3 ) 2 ·6H 2 O and Al(NO 3 ) 3 9H 2 The molar concentration of O is 0.1mol / L; then use deionized water to prepare NaOH with a molar concentration of 0.15mol / L and NaOH with a molar concentration of 0.013mol / L. 2 CO 3 Mix the alkaline solution; pour the above-mentioned mixed salt solution and the alkaline solution into a full-return mixed liquid membrane reactor with a rotation speed of 3000 rpm at the same time at a volume ratio of 1:4, and stir vigorously for 15 minutes; centrifuge and wash the precipitate with deionized water to remove excess acid ions and metal ions; disperse the precipitate in deionized water to prepare a suspension with a mass percentage of 0.07, and add it to a stainless steel autoclave lined with polytetrafluoroethylene, at 100 ° C , hydrothermal reaction for 10 hours, and then naturally cooled to room temp...

Embodiment 2

[0031] A. Prepare ZnCl-containing solution with deionized water 2 and Al(NO 3 ) 3 9H 2 O metal salt solution in which ZnCl 2 The molar concentration of Al(NO 3 ) 3 9H 2 The molar concentration of O is 0.1mol / L; then use deionized water to prepare a NaOH solution with a molar concentration of 0.2mol / L; pour the above mixed salt solution and alkaline solution at a volume ratio of 1:4 at a speed of 4000 rpm In a fully back-mixed liquid membrane reactor per minute, stir vigorously for 10 minutes; centrifuge and wash the precipitate with deionized water to remove excess acid radical ions and metal ions; disperse the precipitate into deionized water to prepare a mass percentage of 0.06 The suspension was added into a stainless steel autoclave lined with polytetrafluoroethylene, hydrothermally reacted at 140°C for 6 hours, and then naturally cooled to room temperature to obtain the product Zn 3 Al-Cl hydrotalcite colloidal solution.

[0032] B. Use an electronic balance to we...

Embodiment 3

[0035] A. Prepare CoCO-containing solution with deionized water 3 and FeCl 3 ·6H 2 O metal salt solution in which CoCO 3 The molar concentration is 1.2mol / L, FeCl 3 ·6H 2 The molar concentration of O is 0.6mol / L; then use deionized water to prepare NaOH with a molar concentration of 0.9mol / L and NaOH with a molar concentration of 0.24mol / L. 2 CO 3 Mix the alkaline solution; pour the above-mentioned mixed salt solution and the alkaline solution into a fully back-mixed liquid membrane reactor with a rotation speed of 5000 rpm at the same time according to the volume ratio of 1:4, and stir vigorously for 5 minutes; centrifuge and wash the precipitate with deionized water to remove excess acid ions and metal ions; disperse the precipitate in deionized water to prepare a suspension with a mass percentage of 0.05, and add it to a stainless steel autoclave lined with polytetrafluoroethylene, at 120 ° C , hydrothermal reaction for 8 hours, and then naturally cooled to room tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com