Ultra-high molecular weight polyethylene composite material for water lubricated bearing

An ultra-high molecular weight, water-lubricated bearing technology, used in bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of water-lubricated friction coefficient, difficult to form complete water-lubrication, etc., to improve wear resistance, improve water The effect of lubricating friction performance and improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

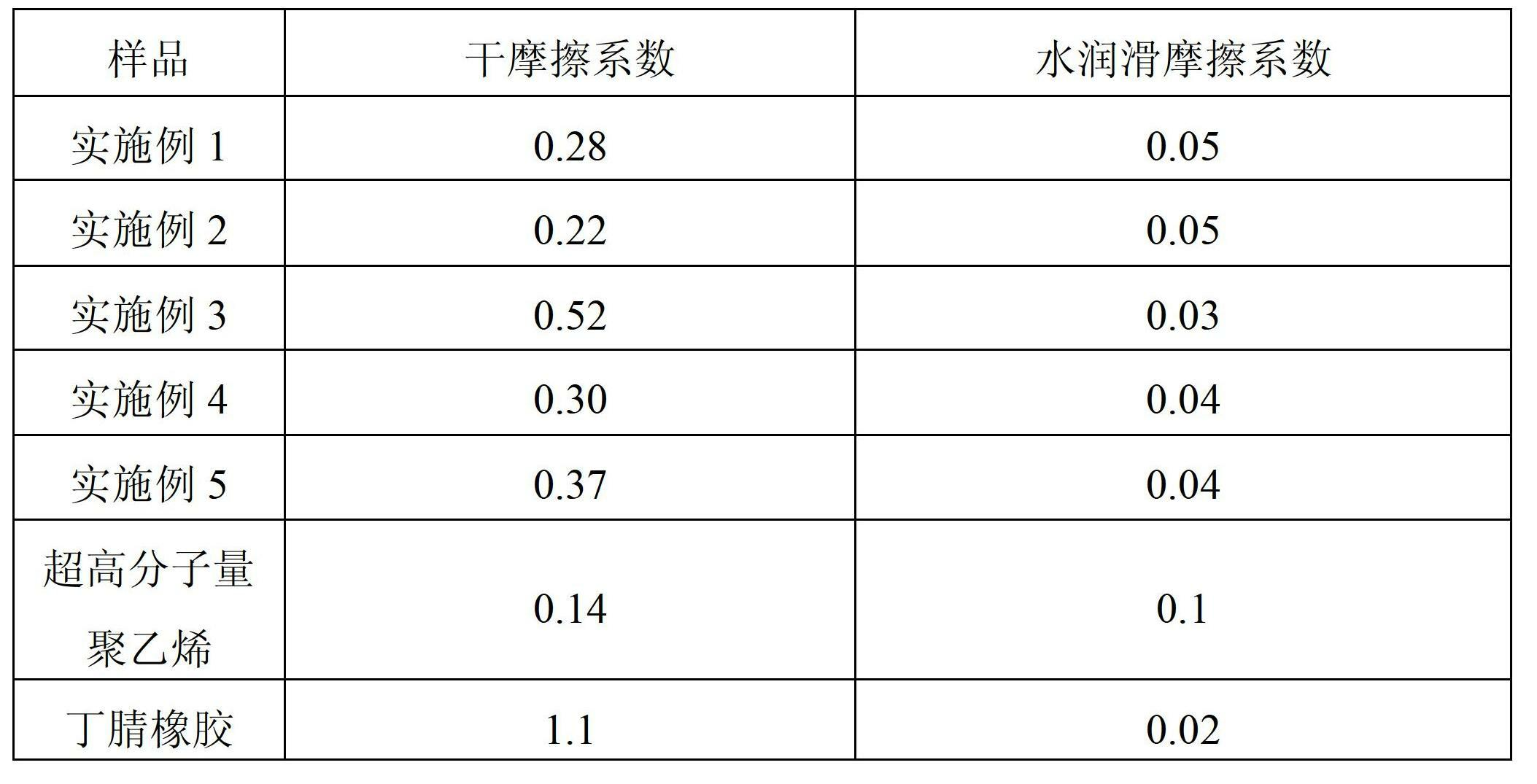

Examples

Embodiment 1

[0017] Take 100 parts of ultra-high molecular weight polyethylene with a molecular weight of 3 million, 30 parts of ordinary nitrile rubber, 10 parts of graphite, 10 parts of molybdenum disulfide, 1.5 parts of zinc oxide, 0.3 parts of stearic acid, and 1 part of dicumyl peroxide. Parts, 0.1 part of β-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate, 2,2,4-trimethyl-1,2-dihydroquinoline polymer 0.1 part, the above components were mixed uniformly in an internal mixer at 120°C, then the mixture was placed in a mold, and molded at 170°C to obtain the ultra-high molecular weight polyethylene composite material of the present invention.

Embodiment 2

[0019] Take 100 parts of ultra-high molecular weight polyethylene with a molecular weight of 5 million, 10 parts of hydrogenated nitrile rubber, 40 parts of graphite, 1.0 part of zinc oxide, 0.3 part of stearic acid, 1,4-bis-(2-tert-butyl peroxide) 0.1 part of cumene oxide, 0.2 part of β-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate, 0.2 part of 1,1,3-tris(2-methyl- 0.3 parts of 4-hydroxy-5-tert-butylphenyl) butane, 0.2 parts of 2,2,4-trimethyl-1,2-dihydroquinoline polymer, the above components were mixed in an internal mixer at 140 ℃, mix evenly, then put the mixture in a mold, and mold it at 190 ℃ to obtain the ultra-high molecular weight polyethylene composite material of the present invention.

Embodiment 3

[0021] Take 100 parts of ultra-high molecular weight polyethylene with a molecular weight of 8 million, 50 parts of carboxylated nitrile rubber, 10 parts of molybdenum disulfide, 5 parts of zinc oxide, 1 part of stearic acid, 1,4-bis-(2-tert-butyl 3 parts of isopropyl peroxide, 1 part of tris(2,4-di-tert-butylphenyl) phosphite, 1 part of 1,1,3-tris(2-methyl-4-hydroxy-5-tert 1 part of butylphenyl)butane, 1 part of 2,2,4-trimethyl-1,2-dihydroquinoline polymer, mix the above components in an internal mixer at 130°C, and then mix the mixture Put it in a mold, and mold it at 180°C to obtain the ultra-high molecular weight polyethylene composite material of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com