Preparation method of p-chlorine methyl cinnamate

A technology of methyl cinnamate and methyl acetate, which is applied in the field of preparation of methyl p-chlorocinnamate, can solve problems such as non-compliance with green production requirements, poor production conditions, and many side reactions, and achieve stable and reliable product quality and responsiveness. The effect of mild conditions and convenient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

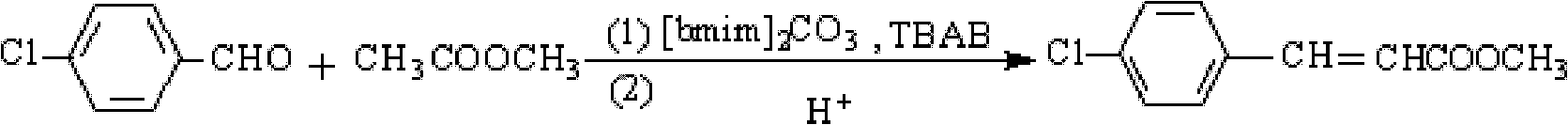

Image

Examples

Embodiment 1

[0026] 0.06mol ionic liquid [bmim] 2 CO 3 , 0.2g (0.0006mol) TBAB and 3.7g (0.05mol) methyl acetate were added in the there-necked flask, and 7.4g (0.0525mol) p-chlorobenzaldehyde was added in 8 batches within 1.0h under stirring, keeping the temperature at Below 5°C, after adding, let it react at room temperature for 2 hours, slowly add 5% sulfuric acid by mass percentage dropwise, so that the pH of the reaction solution is regulated between 6.5 and 7.2; filter, and the obtained filtrate is the mixture of ionic liquid and phase transfer catalyst TBAB The mixture was distilled under reduced pressure to remove water, saturated Na 2 CO 3 After treatment, the obtained solid was washed with hot water at 50-60° C., ice water, and dried to obtain 8.7 g of methyl p-chlorocinnamate with a purity of 98.8% and a yield of 87.4% (calculated as methyl acetate).

Embodiment 2

[0028] 0.14mol ionic liquid [bmim] 2 CO 3 , 0.6g (0.002mol) TBAB and 7.4g (0.1mol) methyl acetate were added in the there-necked flask, and 15.5g (0.11mol) p-chlorobenzaldehyde was added in 8 batches within 1.0h under stirring to keep the temperature at 5 Below ℃, after the addition is completed, let it react at room temperature for 3 hours, slowly add 5% sulfuric acid by mass percentage dropwise, so that the pH of the reaction solution is controlled between 6.5 and 7.2; filter, and the obtained filtrate is a mixture of ionic liquid and phase transfer catalyst TBAB liquid, distilled under reduced pressure to remove water, saturated Na 2 CO 3 After treatment, the obtained solid was washed with hot water at 50-60° C., ice water, and dried to obtain 17.5 g of methyl p-chlorocinnamate with a purity of 99.1% and a yield of 88.2% (calculated as methyl acetate).

Embodiment 3

[0030] 0.24mol ionic liquid [bmim] 2 CO 3 , 1.5g (0.0046mol) TBAB and 11.1g (0.15mol) methyl acetate were added in the there-necked flask, and 25.3g (0.18mol) p-chlorobenzaldehyde was added in 9 batches within 1.5h under stirring to keep the temperature at 5 Below ℃, after adding, make it react at room temperature for 3.5 hours, slowly add 5% sulfuric acid by mass percentage dropwise, so that the pH of the reaction solution is regulated between 6.5 and 7.2; filter, and the obtained filtrate is the mixture of ionic liquid and phase transfer catalyst TBAB The mixture was distilled under reduced pressure to remove water, saturated Na 2 CO 3 After treatment, the obtained solid was washed with hot water at 50-60° C., ice water, and dried to obtain 27.3 g of methyl p-chlorocinnamate with a purity of 99.4% and a yield of 92.0% (calculated as methyl acetate).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com