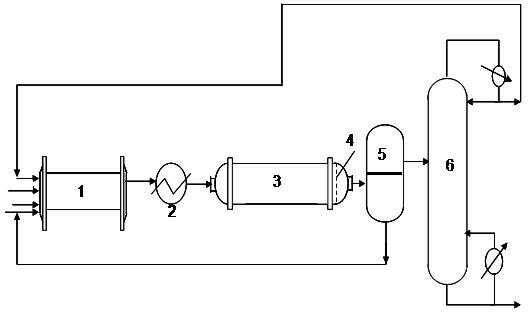

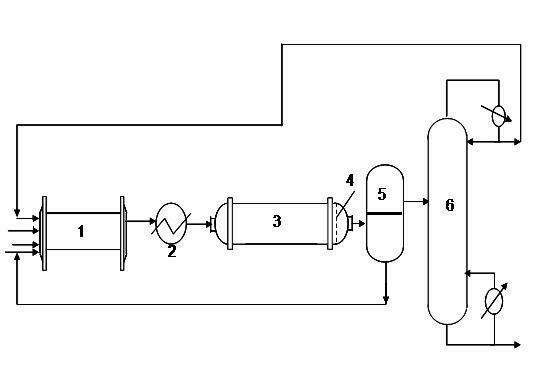

Method for continuously producing dihydromyrcenol by using tubular reactor

A tubular reactor and dihydromyrcenol technology, applied in organic chemistry, hydroxyl addition preparation, etc., can solve the problems of rapid decline in reaction rate, high process energy consumption, low production efficiency, etc., to save equipment investment, The effect of large heat transfer area and high production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1: The mass ratio of dihydromyrcene, water, and isopropanol is 1:1:1, preheated to 80°C after being mixed by a mixer o C, enter the tubular reactor; add Amberlyst 36 strong acid type macroporous cation exchange resin as catalyst in the tubular reactor, the tubular reactor adopts short-circuit current heating, control reaction temperature 110 o C. After the reaction product is filtered through the screen at the outlet of the tubular reactor, the catalyst is retained in the reactor for continued use, and the filtrate enters the phase separator; after the filtrate is separated by the phase separator, the water phase is pumped into the mixer as a raw material Recycling, the upper organic phase enters the rectification tower for further separation; the mixture of dihydromyrcene and solvent extracted from the top of the rectification tower is sent to the mixer as a raw material for continued use, and the product dihydromyrcenol is extracted from the tower reactor, with...

Embodiment 2

[0021] Example 2: Similar to the operation method of Example 1, the mass ratio of dihydromyrcene, water, and butanol is 1:2:2, and it is preheated to 90°C after being mixed by a mixer. o C, enter the tubular reactor; add a certain amount of Amberlyst 15 strong acid type macroporous cation exchange resin in the tubular reactor, control the reaction temperature 100 o C, other operation steps are the same as embodiment 1, and the purity of dihydromyrcenol in the tower kettle is 95.6%. The conversion rate of dihydromyrcene was 94%, and the selectivity was 91%.

Embodiment 3

[0022] Embodiment 3: Similar to the operation method of Embodiment 1, the mass ratio of dihydromyrcene, water and methanol is 1:3:3, preheated to 85 o C, add a certain amount of Amberlyst 35 strong acid type macroporous cation exchange resin in the tubular reactor, control reaction temperature 120 o C, other operation steps are the same as embodiment 1, and the purity of dihydromyrcenol in the tower kettle is 96%. The conversion rate of dihydromyrcene is 90%, and the selectivity is 92%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com