Fluidized bed furnace device for circularly roasting molybdenum concentrates and method for using same

A fluidized furnace, molybdenum concentrate technology, applied in furnaces, fluidized bed furnaces, furnace types, etc., can solve problems such as inability to efficiently produce highly soluble molybdenum oxide, difficulty in comprehensive recycling and acid production, consumption of fuel or other energy, etc. Achieve the effect of improving the working environment of workers, reducing the labor intensity of workers, and reducing the number of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

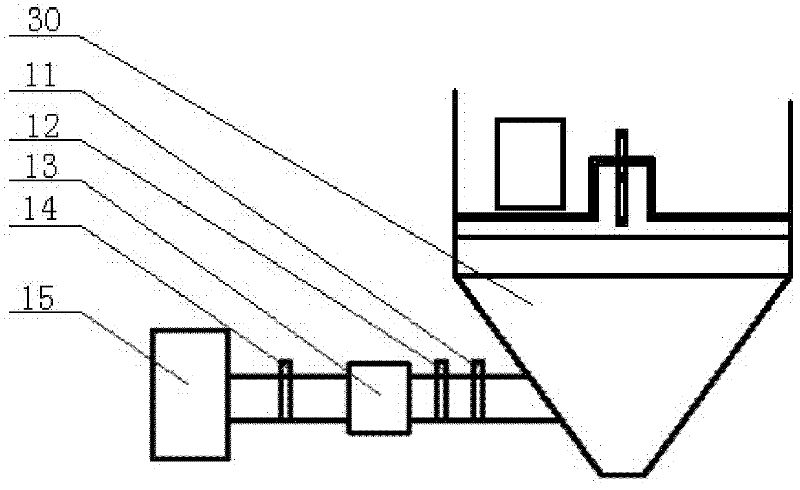

[0041] combine figure 1 The fluidized fluidized furnace 18 of the fluidized fluidized furnace device for circulation roasting molybdenum concentrate is a vertical vertical closed metal cylinder lined with refractory bricks and other corrosion-resistant and high-temperature-resistant materials, with a height of 17 meters and a fluidized layer area of 4.5m 2 , The furnace area of the expansion part is 11.3m 2 , Furnace effective volume 88.4m 3 of the furnace body. It is composed of the air chamber 30 at the lower part of the cylinder, the air distribution device 28 at the upper end of the air chamber, the feed port 10, the discharge port 25, the temperature control device and the smoke outlet 17 at the upper end of the cylinder; the flue gas outlet of the fluidized fluidized furnace is connected to the dust collection system , the dust collection system is further connected to the flue gas recycling system 4; both the dust collection system and the feeding system are conne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com