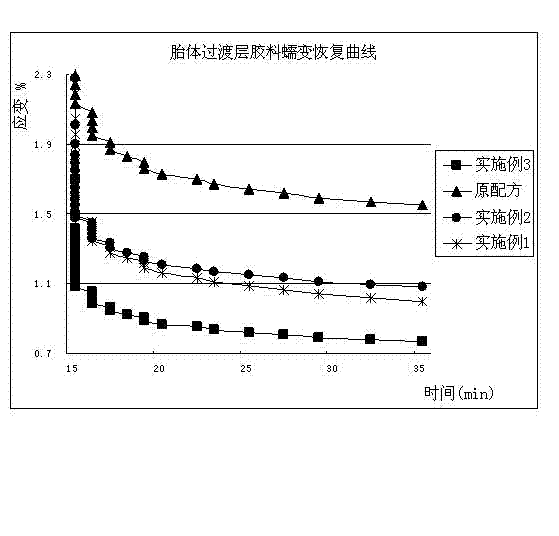

High-modulus low-creep transition layer rubber composition of pneumatic tire body and preparation method of composition

A rubber composition and a technology for pneumatic tires are applied in the rubber field to achieve the effects of increasing the modulus of the rubber compound, reducing the creep of the rubber compound, and improving the safety performance and service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with embodiment the present invention will be further described:

[0025] In the present invention, natural rubber is the main ingredient in the carcass overcoating formula, and the natural rubber has better comprehensiveness and better process viscosity. The natural rubber is 10# and 20# standard rubber produced in Thailand.

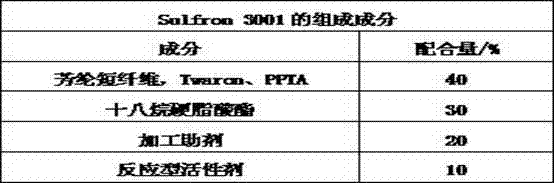

[0026] In the formulation of the present invention, the reinforcing system adopts carbon black N326, uses 1.0-1.5 parts of Sulfron 3001 aramid staple fiber (see Table 1 for its components), and adopts Sulfron 3001 Teijin modified aramid staple fiber, which is a kind of high flexibility Molecular materials, the most notable characteristics are high strength and high modulus, and its strength is greater than 25 grams per denier, which is 5 to 6 times that of high-quality steel. After the aramid staple fiber is used in the formula, the carcass transition layer compound is strengthened. The anti-aging agent N-(1,3-dimethylbutyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com