Preparation method of polyester modified hydroxyl polyacrylate, and paint containing polyester modified hydroxyl polyacrylate

A hydroxyl polyacrylate and polyester modification technology, which is applied in the field of polyacrylate, can solve the problems of poor wetting performance of resins on pigments and fillers, high content of acrylate monomers, and poor compatibility of curing agents, etc., to achieve Excellent physical and chemical properties, good resistance to chemical media, drying speed and grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

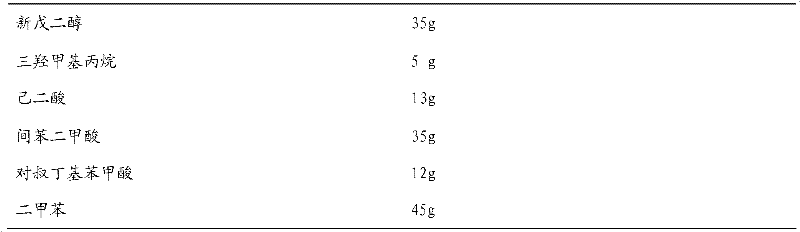

[0037] The consumption of each component of hydroxyl polyester:

[0038]

[0039] Add dihydric alcohol, trihydric alcohol, dibasic acid and monobasic acid into the reaction kettle, reduce pressure and polymerize for 5 hours at a vacuum of 0.02MPa and 180°C, then lower the temperature below 140°C, and add dihydric alcohol and trihydric alcohol , dibasic acid and unit acid total weight 8% xylene, react at 230°C until the acid value of hydroxyl polyester is 18mgKOH / g, cool to 140°C, add xylene to dilute to 70% solid content.

[0040] (2) Hydroxypolyacrylate containing anhydride:

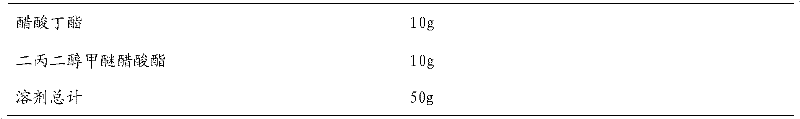

[0041] The consumption of each component of the hydroxyl polyacrylate containing anhydride:

[0042]

[0043]

[0044] Add 50w% organic solvent into the reaction kettle, add the mixture of acrylic acid monomer, initiator and remaining organic solvent dropwise within 3 hours at 120° C., keep it warm for 1 hour; cool down to room temperature to obtain anhydride-containing hydroxyl polyacrylate. ...

Embodiment 2

[0066] The consumption of each component of hydroxyl polyester:

[0067]

[0068] Add diols, triols, dibasic acids and monoacids into the reaction kettle, compress and polymerize under reduced pressure at 0.1MPa and 150°C for 2 hours, then lower the temperature below 140°C, add diols and triols The total weight of dibasic acid and unit acid is 15% xylene, react at 220°C until the acid value is 15mgKOH / g, cool down to 140°C, add xylene to dilute to 70% solid content.

[0069] (2) Hydroxypolyacrylate containing anhydride:

[0070] The consumption of each component of the hydroxyl polyacrylate containing anhydride:

[0071]

[0072]

[0073] Add 80w% organic solvent into the reaction kettle, drop the mixture of acrylic acid monomer, initiator and remaining organic solvent at 135° C. within 3 hours, keep it warm for 1 hour; cool down to room temperature to obtain anhydride-containing hydroxyl polyacrylate.

[0074] (3) Preparation of high solid content polyester modifie...

Embodiment 3

[0094] The consumption of each component of hydroxyl polyester:

[0095]

[0096] Add dihydric alcohol, trihydric alcohol, dibasic acid and monobasic acid into the reaction kettle, reduce pressure and polymerize for 4 hours at a vacuum of 0.08MPa and 160°C, then lower the temperature below 140°C, and add dihydric alcohol and trihydric alcohol , dibasic acid and unit acid total weight 12% xylene, react at 210°C until the acid value of the hydroxyl polyester is 16mgKOH / g, cool to 140°C, add xylene to dilute to 80% solid content.

[0097] (2) Hydroxypolyacrylate containing anhydride:

[0098] The consumption of each component of the hydroxyl polyacrylate containing anhydride:

[0099]

[0100] Add 50w% organic solvent into the reaction kettle, drop the mixture of acrylic acid monomer, initiator and remaining organic solvent at 150° C. within 4 hours, keep it warm for 1 hour; cool down to room temperature to obtain anhydride-containing hydroxyl polyacrylate.

[0101] (3) P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com