Axial diode and fabrication method of axial diode with polyimide glue as protection glue layer

A technology of axial diodes and polyimide glue, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve problems such as low product qualification rate, low production efficiency, and affecting the electrical properties of workpieces, and achieve The method is reasonable, the production efficiency is high, and the effect of improving electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

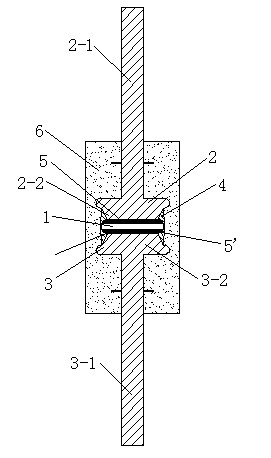

[0028] Such as figure 1 As shown, an axial diode includes a diode chip 1, a first copper electrode 2, a second copper electrode 3, a protective glue layer 4 and an epoxy insulating glue 6; the diode chip 1 is located between the first copper electrode 2 and the second copper electrode Between the two copper electrodes 3, and the positive and negative contact surfaces of the diode chip 1 are welded and connected to the first copper electrode 2 and the second copper electrode 3 respectively through the first soldering adhesive layer 5 and the second soldering adhesive layer 5' respectively. ; The first copper electrode 2 has a first lead 2-1 integrated with it, and the second copper electrode 3 has a second lead 3-1 integrated with it; and it: the first copper electrode 2 has a The first boss 2-2, the second copper electrode 3 has a second boss 3-2, the diode chip 1 is located between the first boss 2-2 and the second boss 3-2; the protective glue layer 4 Coated on the diode c...

specific Embodiment approach 2

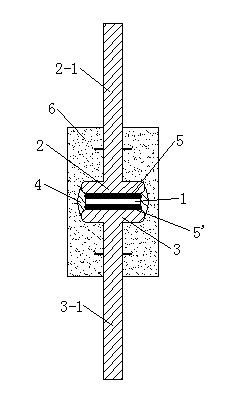

[0030] Such as figure 2 As shown, a method for preparing an axial diode whose protective adhesive layer is polyimide glue, the preparation method includes mounting, welding, pickling, gluing, curing, molding, aging and electroplating, and it:

[0031] a. The mounting step is to pack the first copper electrode 2, the first welding adhesion layer 5, the diode chip 1, the second welding adhesion layer 5' and the second copper electrode 3 into the graphite boat in sequence, and make it close together;

[0032] b. The welding step is to put the graphite boat into the welding furnace for structural welding, the time is within 6-10 minutes, and the temperature is controlled within the range of 300-360°C;

[0033]c, the pickling step is to put the workpiece after the welding step into the through hole of the pickling plate, then inject the mixed pickling solution into the working concave surface of the pickling plate to corrode the periphery of the diode chip 1, and the time is cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com