Sealing agent for aluminum and aluminum alloy anode oxide films and preparation method for sealing agent

A technology of anodic oxidation film and sealing agent, which is applied in the direction of electrolytic coating, surface reaction electrolytic coating, coating, etc., can solve the problems of unfavorable performance and environment of aluminum and aluminum alloy anodic oxidation film, poor stability of sealing liquid, sealing liquid High temperature and other problems, to achieve the effect of improving convenience, not easy to decompose, and improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 17g of Ce(NO 3 ) 3 Add 800mL of deionized water, stir well, then add 0.6g of KMnO 4 , stir evenly, then add 0.27g of K under stirring 4 P 2 o 7 , add deionized water to make up to 1 L to obtain a blocking agent.

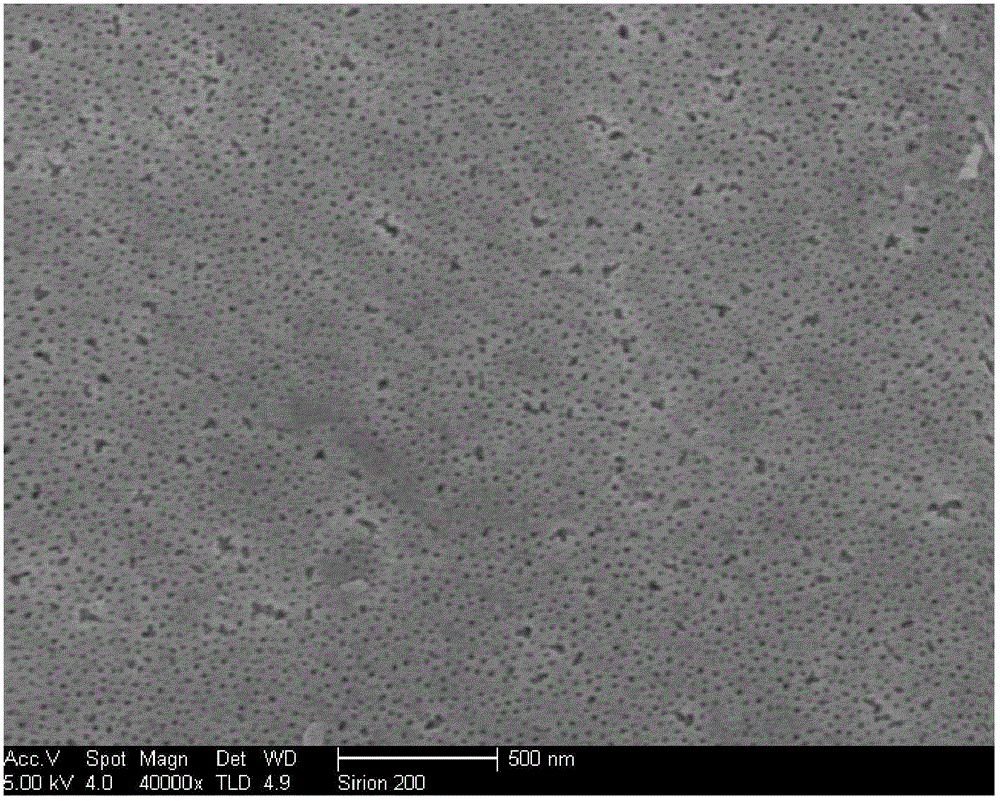

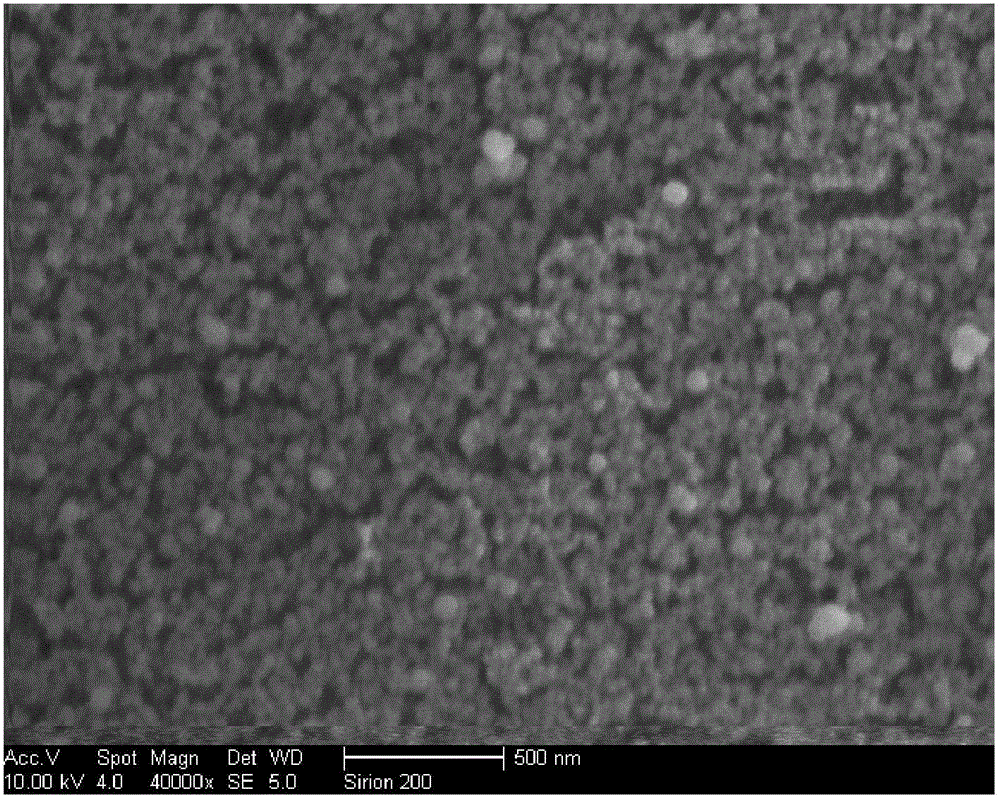

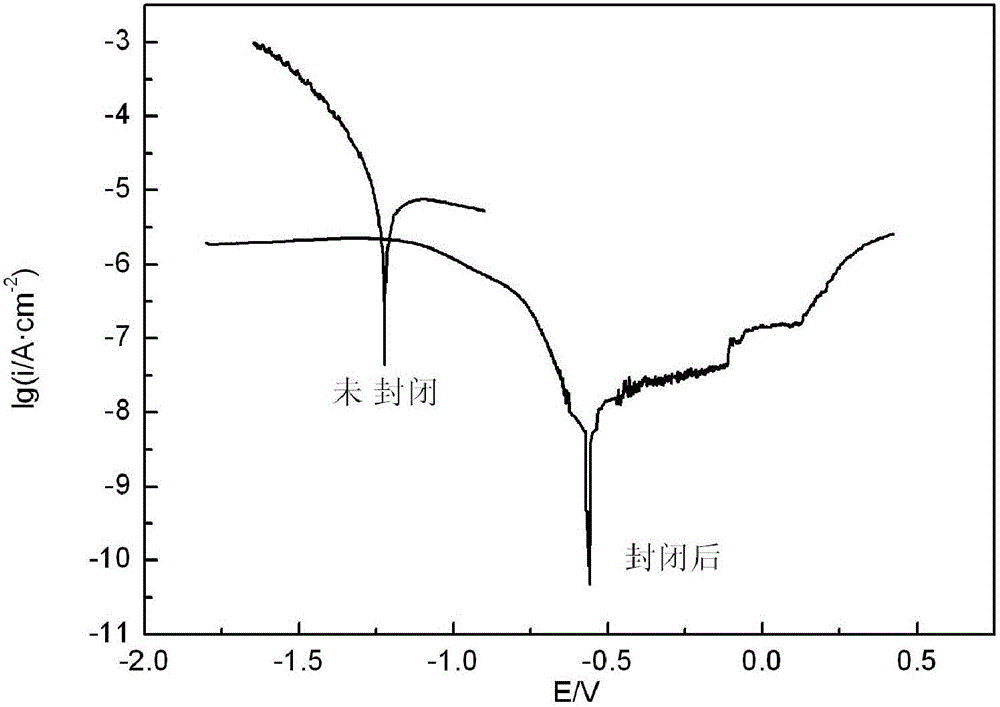

[0034] The anodized 6063 aluminum alloy is placed in a sealing agent for sealing treatment, the temperature is 27° C., and the time is 40 minutes. The surface of the aluminum alloy anodized film after sealing is uniform golden yellow, and its scanning electron microscopic image can be seen in figure 2 ; Its polarization curve in 1mol / L HCl solution is shown in image 3 , the polarization curve in 1mol / L NaOH solution is shown in Figure 5 ; Its AC impedance curves in the corresponding acid and alkali are shown in Figure 4 and Figure 6 , the sealing treatment of the present invention significantly improves the corrosion resistance of the aluminum alloy anodized film.

Embodiment 2

[0036] 18g of Y (NO 3 ) 3 Pour into 800mL deionized water, stir well, then add 0.5 KMnO 4and 0.2g of 30% H 2 o 2 , stir evenly; add 0.3g of Na under stirring 4 P 2 o 7 , add deionized water to make up to 1 L to obtain a blocking agent.

[0037] The anodized 6063 aluminum alloy is placed in a sealing agent for sealing treatment, the temperature is 30° C., and the time is 35 minutes. The surface of the aluminum alloy anodic oxide film after sealing is uniform golden yellow, and its full immersion test result comparison with the unsealed anodic oxide film in 1mol / L HCl solution is shown in Table 1, and the sealing treatment of the present invention has significantly improved the aluminum alloy anode. Corrosion resistance of oxide film.

Embodiment 3

[0039] 15g of Nd(NO 3 ) 3 Pour into 800mL deionized water, stir well, then add 0.8g of NaClO 4 ·H 2 O, stir evenly; add 0.25g of Na under stirring 4 P 2 o 7 , add deionized water to make up to 1 L to obtain a blocking agent.

[0040] The anodized 6063 aluminum alloy is placed in a sealing agent for sealing treatment, the temperature is 35° C., and the time is 35 minutes. The surface of the aluminum alloy anodic oxide film after sealing is uniform golden yellow, and it compares with the full immersion test result of the unsealed anodic oxide film in Table 2 in 1mol / L NaOH solution, and the sealing treatment of the present invention has significantly improved the aluminum alloy anode. Corrosion resistance of oxide film.

[0041] Table 1

[0042]

[0043] Table 2

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com