Lead lutecium niobate-lead zirconate titanate piezoceramic material

A technology of piezoelectric ceramics and lead zirconate titanate, which is applied in the direction of piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc., can solve the problems of no application and difficult growth of ferroelectric single crystal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1. Weigh Lu according to the stoichiometric ratio 2 o 3 , Nb 2 o 5 , adding absolute ethanol as the medium, planetary ball milling for 12 hours, drying at 120°C, and calcining at 1150°C for 1.5 hours to obtain the precursor LuNbO 4 .

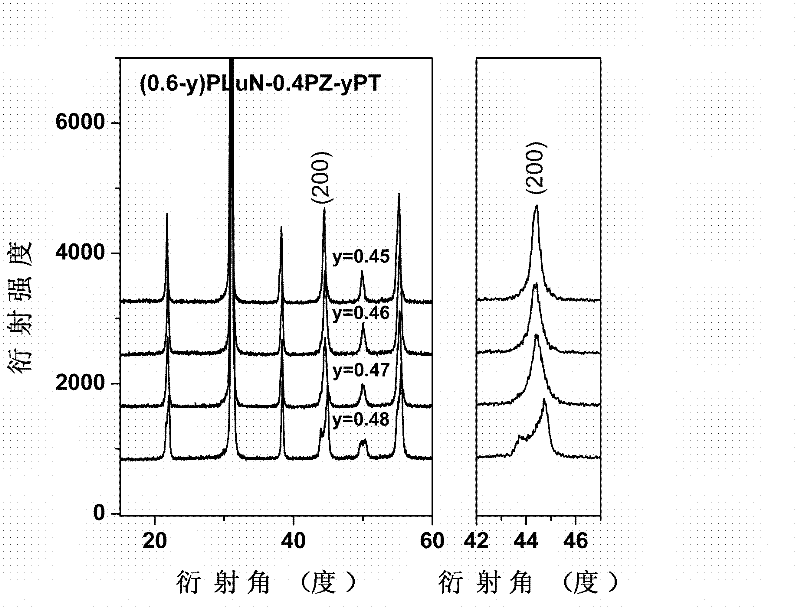

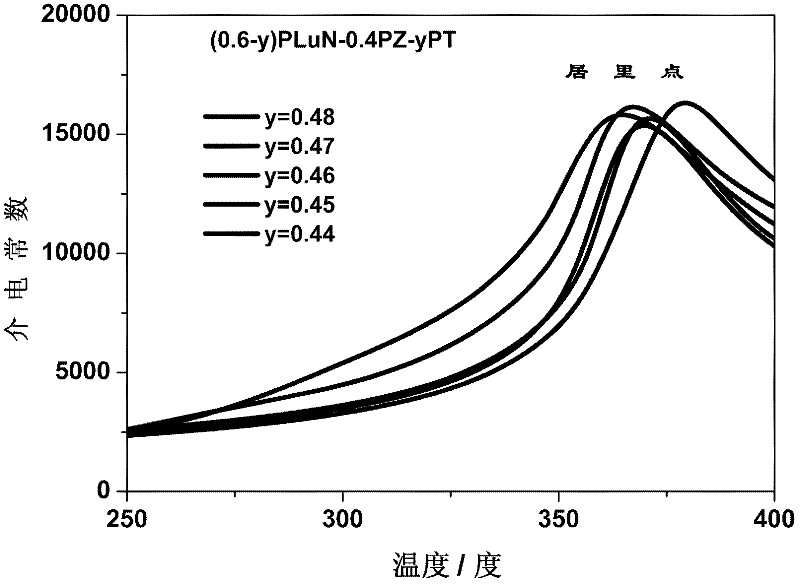

[0021] 2. According to the general formula (1-x-y)Pb(Lu 1 / 2 Nb 1 / 2 )O 3 -xPbZrO 3 -yPbTiO 3 , where x=0.40 and y take values of 0.40, 0.44, 0.45, 0.46, 0.47, 0.48, 0.50 respectively. Weigh LuNbO according to the stoichiometric ratio 4 , ZrO 2 ,TiO 2 . Let weigh more than 3% of the stoichiometric PbO to compensate for its volatilization during the sintering process; add absolute ethanol as a medium, and grind the planetary ball for 24 hours.

[0022] 3. The output is dried, and the dried mixture is compressed into Al 2 o 3 In a crucible, it was synthesized at 800°C for 6 hours.

[0023] 4. Crush the synthetic material, use absolute ethanol as the medium, and planetary ball mill again for 12 hours to make it evenly mixed. ...

Embodiment 2

[0031] 1. Weigh Lu according to the stoichiometric ratio 2 o 3 , Nb 2 o 5 , adding absolute ethanol as the medium, planetary ball milling for 12 hours, drying at 120°C, and calcining at 1150°C for 1.5 hours to obtain the precursor LuNbO 4 .

[0032] 2. According to the general formula (1-x-y)Pb(Lu 1 / 2 Nb 1 / 2 )O 3 -xPbZrO 3-yPbTiO 3 , where x=0.25 and y take values of 0.41, 0.42, 0.43, 0.45, 0.46, 0.47, 0.48 respectively. Weigh LuNbO according to the stoichiometric ratio 4 , ZrO 2 ,TiO 2 . Let weigh more than 3% of the stoichiometric PbO to compensate for its volatilization during the sintering process; add absolute ethanol as a medium, and grind the planetary ball for 24 hours.

[0033] 3. The sintering temperature is set at 1100°C for 2.5 hours.

[0034] 3. All the other are with embodiment 1.

Embodiment 3

[0036] 1. Weigh Lu according to the stoichiometric ratio 2 o 3 , Nb 2 o 5 , adding absolute ethanol as the medium, planetary ball milling for 12 hours, drying at 120°C, and calcining at 1150°C for 1.5 hours to obtain the precursor LuNbO 4 .

[0037] 2. According to the general formula (1-x-y)Pb(Lu 1 / 2 Nb 1 / 2 )O 3 -xPbZrO 3 -yPbTiO 3 , where x=0.10 and y take values of 0.40, 0.43, 0.44, 0.45, 0.46, 0.47, 0.48, 0.50 respectively. Weigh LuNbO according to the stoichiometric ratio 4 , ZrO 2 ,TiO 2 . Let the PbO exceeding the stoichiometric ratio of 3% be weighed; add absolute ethanol as a medium, and planetary ball mill for 24 hours.

[0038] 3. The sintering temperature is set at 1020° C. for 2.5 hours.

[0039] 3. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com