Preparation method of sodium bichromate

A kind of technology of sodium red vanadium and crystal seed, applied in the field of preparing sodium vanadium, and can solve the problems of complicated process control, product quality influence, mirabilite and waste residue pollution and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

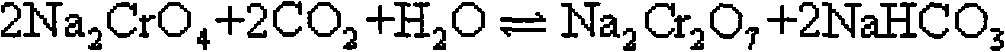

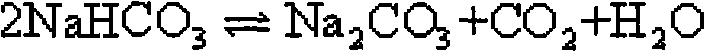

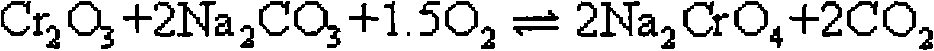

Method used

Image

Examples

Embodiment 1

[0050] ①Will 0.5m 3 Take Na 2 Cr 2 o 7 2H 2 The concentration of chromium compound in O is 750g·L -1 The aqueous solution containing sodium chromate is added into a single carbonization reactor, and the aqueous solution is obtained by neutralizing the sodium chromate alkaline solution obtained in the industrial process of roasting chromite to produce sodium chromate through carbon dioxide and removing aluminum. Aqueous solution of sodium bicarbonate;

[0051] ② Continuously feed a mixed gas containing 80% by volume of carbon dioxide and 20% by volume of air into the carbonization reactor, control the partial pressure of carbon dioxide in the carbonization reactor to 1.2MPa and the reaction temperature to 95°C, and keep it under this condition for 7.5h;

[0052] ③The carbonized feed liquid obtained in step ② is separated from solid and liquid using a vacuum belt filter to obtain carbonized liquid and sodium bicarbonate crystals. 2 Cr 2 o 7 2H 2 The concentration of chr...

Embodiment 2

[0055] ①Will 0.5m 3 Take Na 2 Cr 2 o 7 2H 2 The concentration of chromium compound in O is 1300g·L -1 The aqueous solution containing sodium chromate is added in three carbonization reactors connected in series, and the aqueous solution is obtained by neutralizing and removing aluminum from the sodium chromate alkaline solution obtained in the process of roasting chromite ore in the industry to produce sodium chromate Aqueous solutions containing sodium chromate;

[0056] ② Continuously feed a mixed gas containing 85% by volume of carbon dioxide and 15% by volume of air into the carbonization reactor, control the partial pressure of carbon dioxide in the three reactors to be 1.0MPa and the reaction temperature to be 30°C, and maintain 1.0h, that is, the total residence time from entering the first reactor to flowing out of the third reactor is 1h;

[0057] 3. The carbonized feed liquid obtained in step 2. adopts a vacuum belt filter to carry out solid-liquid separation t...

Embodiment 3

[0060] ①Will 0.5m 3 Take Na 2 Cr 2 o 7 2H 2 The concentration of chromium compound in O is 950g·L -1 The aqueous solution containing sodium chromate and 45kg sodium bicarbonate seed crystals are added in a single carbonization reactor. And the aqueous solution containing sodium chromate obtained by removing aluminum;

[0061] ② Continuously feed a mixed gas containing 10% by volume of carbon dioxide and 90% by volume of air into the carbonization reactor, control the partial pressure of carbon dioxide in the carbonization reactor to 0.1MPa and the reaction temperature to 15°C, and keep it under this condition for 8.0h;

[0062] 3. The carbonized feed liquid obtained in step 2. is separated from solid and liquid by a membrane filter press to obtain carbonized liquid and sodium bicarbonate crystals. The carbonized liquid is prepared with Na 2 Cr 2 o 7 2H 2 The concentration of chromium compound in O is 950g·L -1 , and the transformation rate of sodium chromate into sod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com