Hydrogenation active protective agent with aluminum oxide as carrier and preparation as well as application thereof

A hydrogenation activity protection, alumina carrier technology, applied in the direction of metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of downstream catalyst deactivation, and achieve Good hydrodemetallization activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1 illustrates the alumina carrier used in the catalyst provided by the present invention and its preparation method.

[0033] Example 1

[0034] Take by weighing the dry rubber powder (dry basis is 73% that Changling Refinery Catalyst Factory produces, and wherein pseudo-boehmite content is 68%, and gibbsite content is 5 weight %, and surplus is amorphous alumina) 1000 Gram,, 30 gram turmeric powder (Henan Lankao turmeric glue factory product), 30g hydroxymethyl cellulose mixes, add the aqueous solution 1200 milliliters that contains nitric acid 16g afterwards, extrude into outer diameter 2.5mm on the plunger type extrusion machine, Raschig ring bar with inner diameter of 1.0mm. The wet strip was dried at 120°C for 4 hours and calcined at 960°C for 3 hours to obtain carrier Z1. The pore volume of carrier Z1 is 0.73mL / g, and the specific surface area is 118m 2 / g.

Embodiment 2

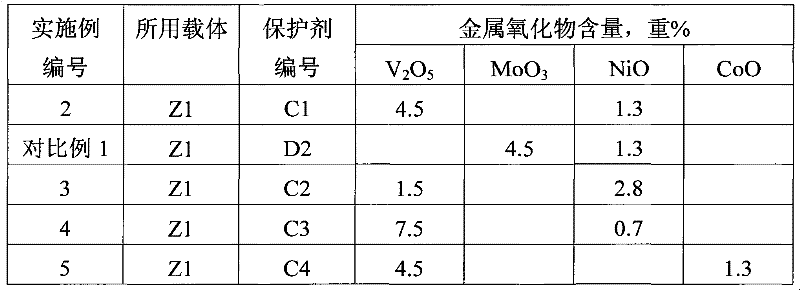

[0037] Get the carrier Z1200 grams that embodiment 1 prepares, use 500 milliliters to contain V 2 o 5 50 g / L, NiO14 g / L mixed solution of ammonium metavanadate and nickel nitrate was impregnated for 1 hour, filtered, dried at 120°C for 4 hours, and calcined at 400°C for 3 hours to obtain protective agent CZ1. The composition of protective agent CZ1 is listed in Table 1.

Embodiment 3

[0041] Get the carrier Z1200 grams that embodiment 1 prepares, use 500 milliliters to contain V 2 o 5 18 g / L, NiO 24 g / L mixed solution of ammonium metavanadate and nickel nitrate was impregnated for 1 hour, filtered, dried at 120°C for 4 hours, and calcined at 400°C for 3 hours to obtain protective agent C2. The composition of protective agent C2 is listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com