Light-emitting diode (LED) fluorescent diaphragm and LED illuminating lamp based on LED florescent diaphragm

A technology of LED chip and fluorescent film, which is applied in the field of LED lighting fixtures, can solve the problems of limited LED light luminous efficiency, LED failure to emit light, loss of lighting or display functions, etc., to protect eyesight, improve color rendering quality, high The effect of luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

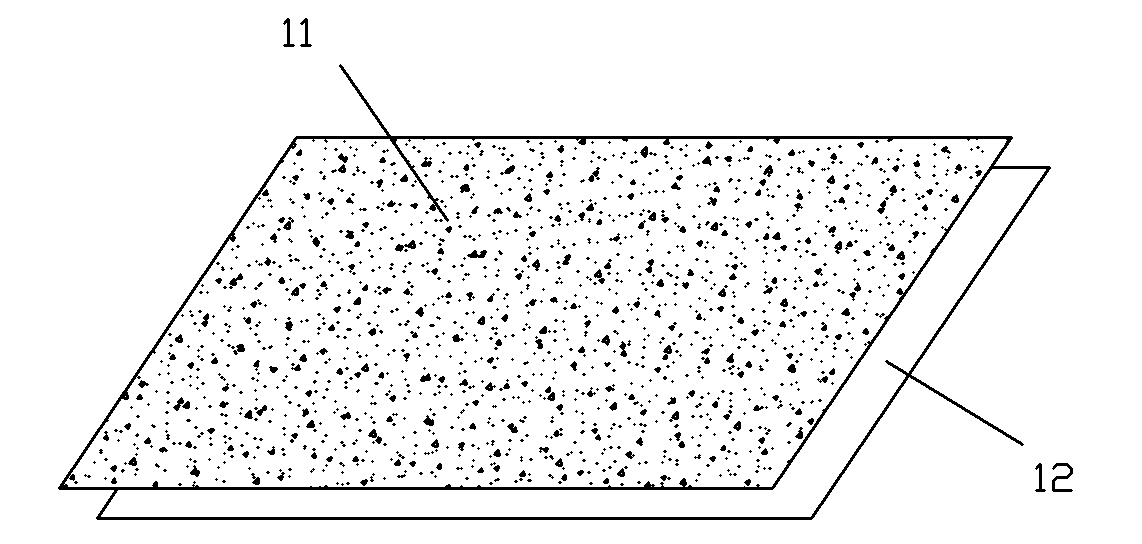

[0030] Embodiment one, see figure 1As shown, a LED fluorescent film of the present invention is composed of a fluorescent film layer 11, and the production of the fluorescent film layer 11 is formed by firstly mixing transparent colloids such as epoxy resin, silicone resin or ink and fluorescent powder raw materials uniformly. Phosphor powder colloid, and then use the printing process to uniformly print the phosphor powder colloid on the support mold 12, and finally remove it from the support mold after heating and drying or drying at room temperature;

[0031] Wherein, the phosphor raw material is one or two of yellow YAG phosphor, yellow TAG phosphor, green aluminate phosphor, red silicate phosphor or red nitride phosphor;

[0032] The weight ratio of phosphor raw materials is 10% to 90%;

[0033] 10% to 90% by weight of epoxy resin, silicone resin or ink;

[0034] The thickness of the fluorescent film layer is 0.1 mm to 3 mm.

[0035] The shape of the fluorescent film la...

Embodiment 2

[0038] Embodiment two, see figure 2 As shown, a LED fluorescent film of the present invention is composed of a fluorescent film layer 21 and a thin supporting light-transmitting film 22, and the fluorescent film layer 21 is made on the supporting light-transmitting film 22 by pasting; The production of fluorescent film layer 21 is to firstly mix transparent colloids such as epoxy resin, silicone resin or ink with fluorescent powder raw materials to form fluorescent powder colloids, and then use printing technology to evenly print phosphor powder colloids on the supporting light-transmitting film 22 , and finally made on the supporting light-transmitting film 22 after heating and drying or drying at room temperature;

[0039] Wherein, the phosphor raw material is one or two of yellow YAG phosphor, yellow TAG phosphor, green aluminate phosphor, red silicate phosphor or red nitride phosphor;

[0040] The weight ratio of phosphor raw materials is 10% to 90%;

[0041] 10% to 90%...

Embodiment 3

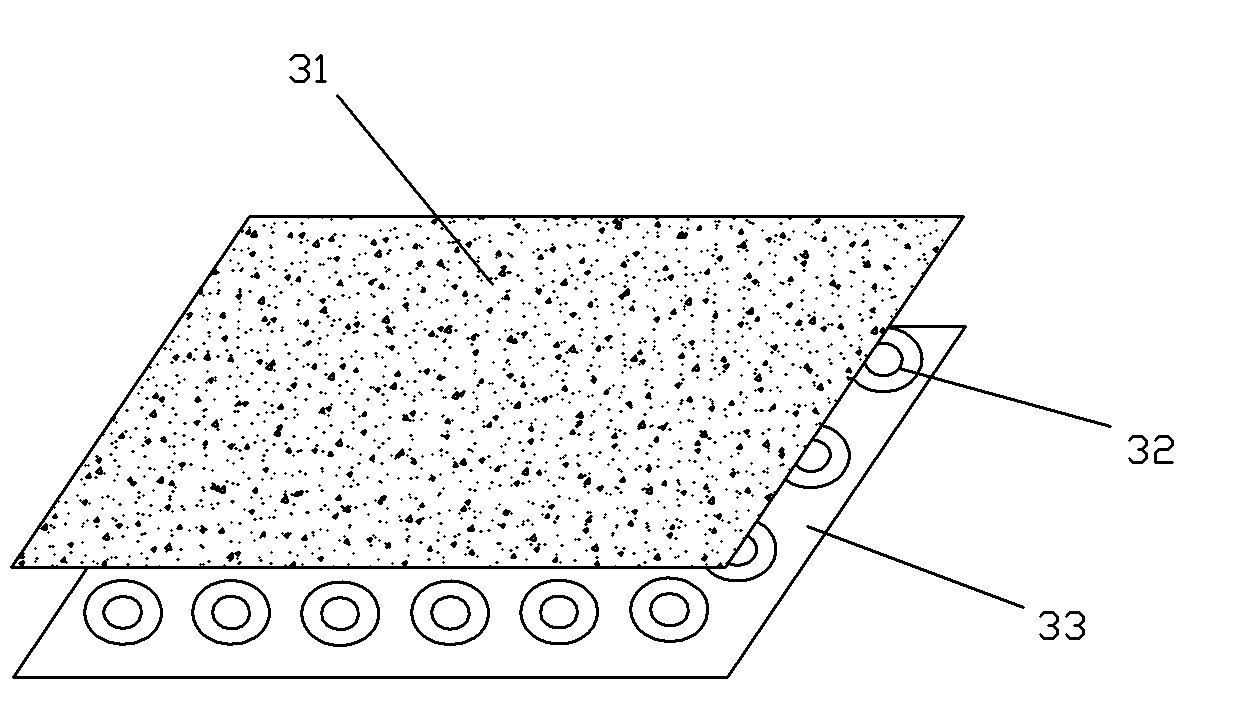

[0046] Embodiment three, see image 3 As shown, a LED lighting fixture based on the above-mentioned LED fluorescent film of the present invention includes an LED fluorescent film 31 and a lamp support frame 33 (a schematic diagram) equipped with a blue LED chip or an ultraviolet LED chip 32; the LED The fluorescent film 31 is covered and fixed on a fixed or adjustable spacing lamp support frame 33 at a certain distance, and there is a preset between the bottom end surface of the LED fluorescent film 31 and the upper end surface of the blue LED chip or the ultraviolet LED chip 32. cavities with a certain distance.

[0047] Wherein, the LED fluorescent film 31 may be the LED fluorescent film produced in the first embodiment, or the LED fluorescent film produced in the second embodiment.

[0048] The invention can produce LED lighting fixtures of various geometric shapes.

[0049] According to user's preferences and different purposes, the present invention can select different...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com