Low-acid phenolic resin foam and preparation method thereof

A technology of phenolic resin foam and low acidity, which is applied in the field of phenolic resin foam and its preparation, can solve problems such as no effect data, and achieve the effects of easy operation, reduced corrosion, and simplified operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

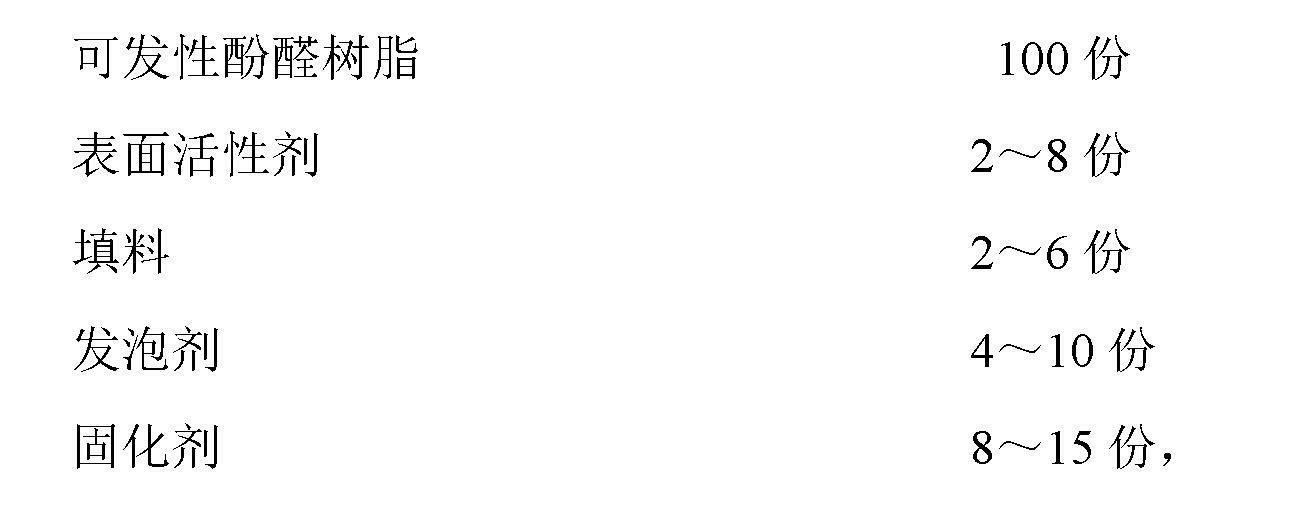

Method used

Image

Examples

Embodiment 1

[0029] Put stearic acid and magnesium oxide powder with a mass ratio of 1:1 into a container, heat and stir continuously in a water bath at 80°C until the stearic acid gradually melts and coats the magnesium oxide powder, then cools. Then it is pulverized and sieved to obtain a filler with a particle size of 80 mesh.

[0030] Add 100 parts of expandable phenolic resin, 4 parts of op-10, and 5 parts of 80-mesh magnesium oxide / stearic acid filler synthesized by the aforementioned method into a high-speed mixer at room temperature and mix evenly, then add 4 parts of n-pentane Add and continue stirring to mix evenly, then add 12 parts of concentrated hydrochloric acid and stir rapidly for 1 minute, then pour the mixture into a preheated mold, place it in an environment of 70°C for foaming and curing for 10 minutes.

[0031] Dip a small amount of water with broad pH test paper to test the pH of the foam to 5-6.

Embodiment 2

[0033] Put stearic acid and magnesium oxide powder with a mass ratio of 1:1 into a container, heat and stir continuously in a water bath at 80°C until the stearic acid gradually melts and coats the magnesium oxide powder, then cools. Then it is pulverized and sieved to obtain a filler with a particle size of 160 mesh.

[0034] Add 100 parts of expandable phenolic resin, 2 parts of op-10, and 2.5 parts of 160-mesh magnesium oxide / stearic acid filler synthesized according to the aforementioned method into a high-speed mixer at room temperature and mix evenly, then add 6 parts of cyclopentane Add and continue stirring to mix evenly, then add 12 parts of concentrated hydrochloric acid and stir quickly for 2 minutes, then pour the mixture into a preheated mold, place it in an environment of 80°C for foaming and curing for 20 minutes.

[0035] Dip a small amount of water with broad pH test paper to test the pH of the foam to 5-6.

Embodiment 3

[0037] First add solid paraffin and nano-calcium carbonate powder with a mass ratio of 1:1 into the container, heat and stir continuously in a water bath at 80°C until the solid paraffin is gradually melted and coated on the nano-calcium carbonate powder, and then cooled. Then it is pulverized and sieved to obtain a filler with a particle size of 40 mesh.

[0038]Add 100 parts of expandable phenolic resin, 8 parts of Tween-80, and 6 parts of 40-mesh solid paraffin / calcium carbonate filler synthesized according to the aforementioned method into a high-speed mixer at room temperature and mix evenly, then mix 6 parts of cyclopentane Add and continue stirring to mix evenly, then add 8 parts of concentrated hydrochloric acid and stir rapidly for 1 minute, then pour the mixture into a preheated mold, place it in an oven at 60°C for foaming and curing for 30 minutes.

[0039] Dip a small amount of water with broad pH test paper to test the pH of the foam to 5-6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com