Terbinafine hydrochloride solid dispersoid and tablet thereof

A technology of terbinafine hydrochloride and solid dispersion, which is applied in the directions of pill delivery, antifungal agent, organic active ingredients, etc. The effect of active ingredient dosage, maintaining drug efficacy and improving in vitro dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

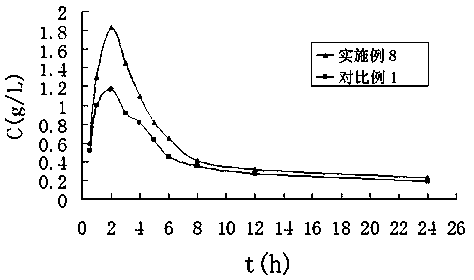

Image

Examples

Embodiment 1

[0025] Preparation of Terbinafine Hydrochloride Solid Dispersion

[0026] Take 50g of poloxamer 188 into a suitable container, place it in a water bath at 65°C-68°C and heat it to a molten liquid state, add 10g of terbinafine hydrochloride fine powder, and stir rapidly at 63°C-66°C until it is evenly mixed. Stand still to remove air bubbles, spread the mixture into a thin layer and put it in a -5°C refrigerator for rapid cooling. After the mixture is completely solidified, take it out, crush it, and dry it in a vacuum dryer at 35°C for 24 hours, and crush it through an 80-mesh sieve to obtain Terbinafine hydrochloride solid dispersion.

Embodiment 2

[0028] Preparation of Terbinafine Hydrochloride Solid Dispersion

[0029] Take 10g of terbinafine hydrochloride and add it to 200mL of water and ethanol for ultrasonic dissolution; take 150g of polyoxyethylene (40) stearate and heat it to 60°C-62°C to make it into a molten liquid state, and add the prepared The ethanol solution of terbinafine hydrochloride was evaporated to dryness, put into a refrigerator at -5°C for rapid cooling, and pulverized through an 80-mesh sieve to obtain a solid dispersion of terbinafine hydrochloride.

Embodiment 3

[0031] Preparation of Terbinafine Hydrochloride Solid Dispersion

[0032] Take 20g of poloxamer 188 into a suitable container, place it in a water bath at 65°C-68°C and heat it to a molten liquid state, add 10g of terbinafine hydrochloride fine powder, stir rapidly at 63°C-66°C until the mixture is uniform, Stand still to remove air bubbles, spread the mixture into a thin layer and put it in a -5°C refrigerator for rapid cooling. After the mixture is completely solidified, take it out and pulverize it, dry it in a vacuum dryer at 35°C for 24 hours, and pulverize it through an 80-mesh sieve to obtain Terbihydrochloride Nafine solid dispersion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com