Micro-nano-structure anode material for Li-air battery and preparation method of micro-nano-structure anode material

A lithium-air battery and positive electrode material technology, applied in battery electrodes, structural parts, circuits, etc., can solve the problems of inability to exert electrochemical performance, large catalyst particle size, and reduced battery capacity, and achieve good ion transmission capacity and preparation process Simple and feasible, the effect of smooth oxygen diffusion channel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

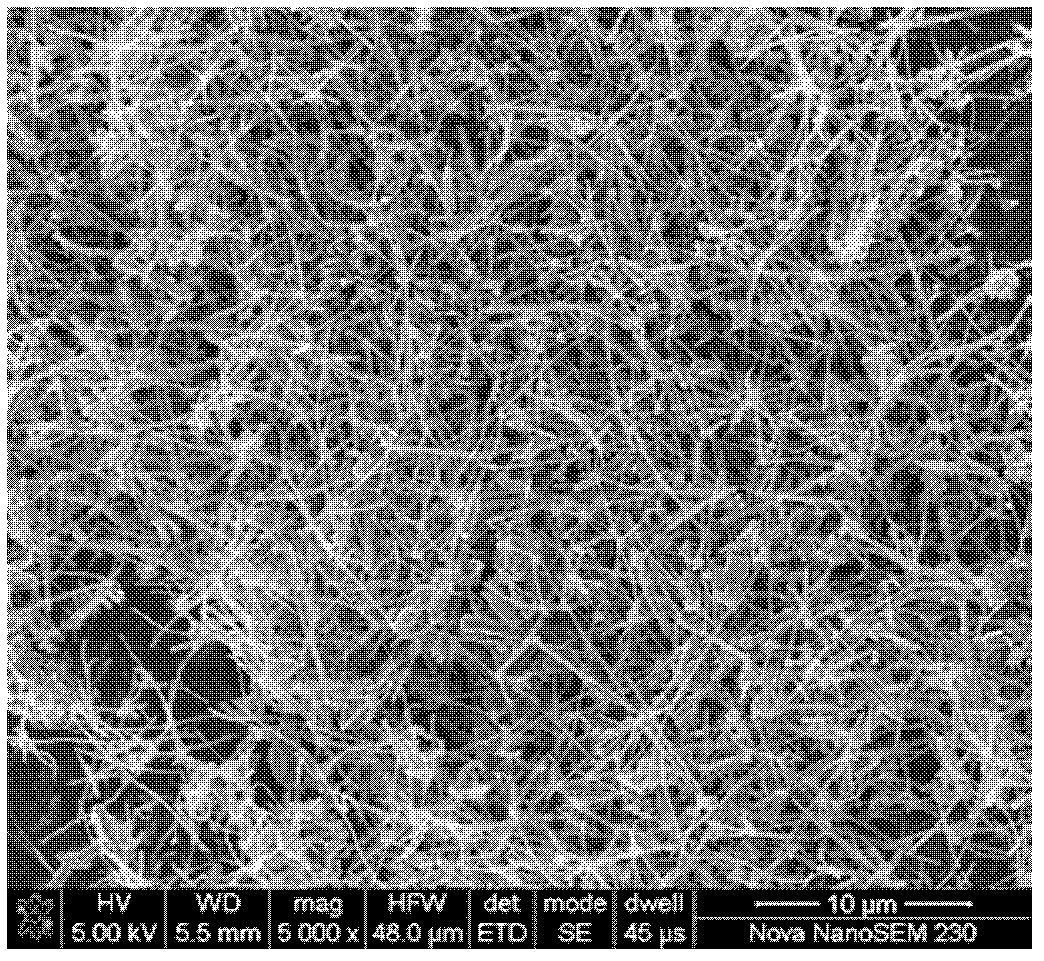

[0045] Weigh 1.8g polyacrylonitrile (PAN), add 15mL N,N-dimethylformamide (DMF), stir in a 60°C water bath for 3h, then add 5g ammonium molybdate, stir for 1h, control voltage 11kV, indirect The collection distance is 15cm, the liquid flow rate is 30μl / min, and the PAN / ammonium molybdate hollow fiber is obtained through the electrospinning process. The obtained composite fibers were put into a tube furnace and pretreated at 250°C for 1 h. Under an ammonia atmosphere, the nitriding temperature is 800°C, and the heating rate is 3°C / min, the hollow composite fiber is nitrided to obtain the hollow carbon / molybdenum nitride composite fiber. The obtained material was mixed with potassium hydroxide in a ratio of 1:4, and chemically activated at 800 ° C for 2 h under the protection of argon, and then changed to CO 2 The gas is physically activated and kept for 1 hour to obtain porous hollow carbon / molybdenum nitride fibers.

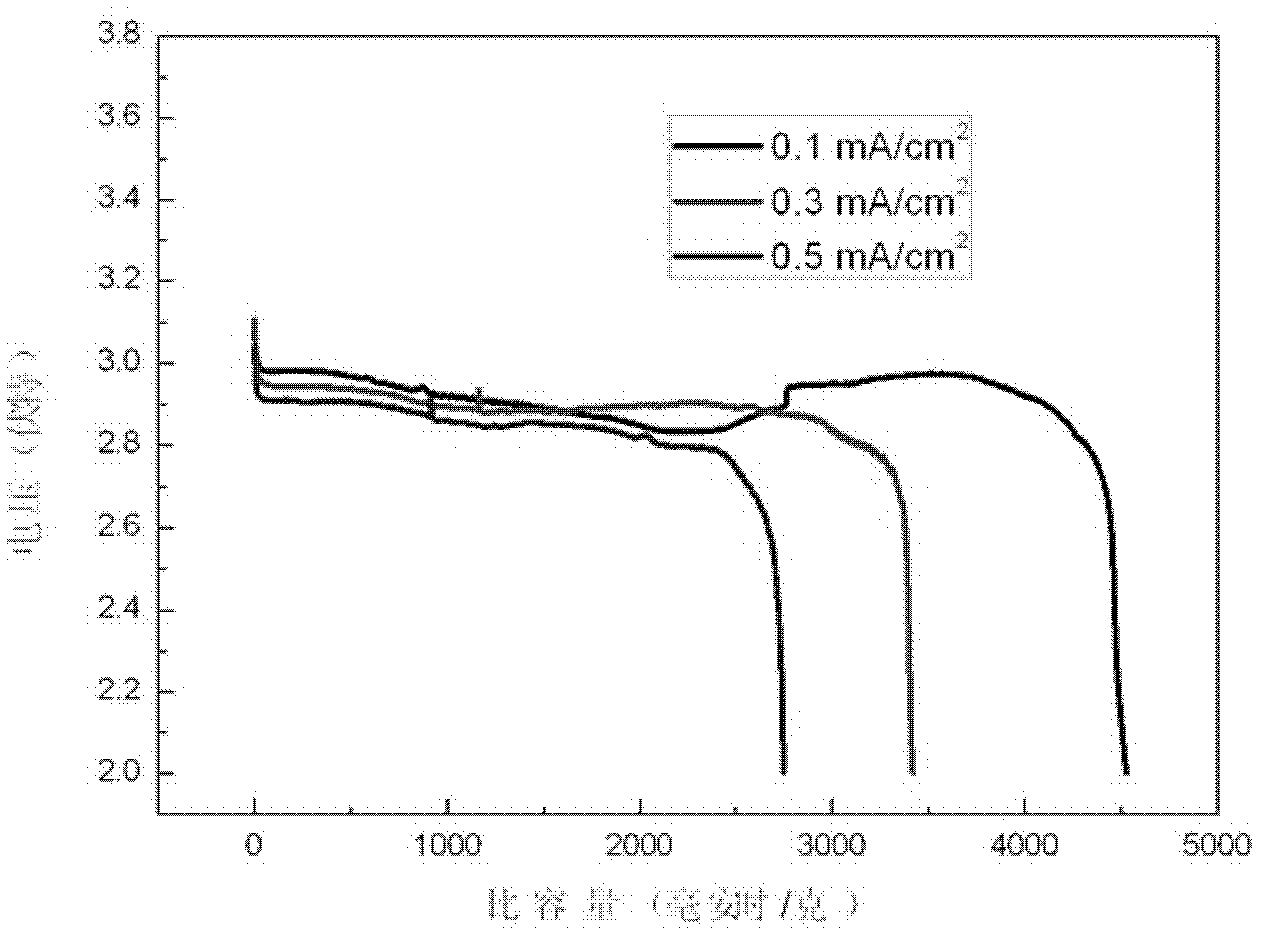

[0046] Electrode preparation, battery assembly and testin...

Embodiment 2

[0048] Weigh 1.8g polyacrylonitrile (PAN), add 15mL N,N-dimethylformamide (DMF), stir in a 60°C water bath for 3h, then add 1g ammonium molybdate, stir for 1h, control voltage 11kV, indirect The collection distance is 15cm, the liquid flow rate is 30μl / min, and the PAN / ammonium molybdate hollow fiber is obtained through the electrospinning process. The obtained composite fibers were put into a tube furnace and pretreated at 250°C for 1 h. Under an ammonia atmosphere, the nitriding temperature is 800°C, and the heating rate is 3°C / min, the hollow composite fiber is nitrided to obtain the hollow carbon / molybdenum nitride composite fiber. The obtained material was mixed with potassium hydroxide in a ratio of 1:4, and chemically activated at 800 ° C for 2 h under the protection of argon, and then changed to CO 2 The gas is physically activated and kept for 1 hour to obtain porous hollow carbon / molybdenum nitride fibers.

[0049] Pole sheet preparation and battery assembly are th...

Embodiment 3

[0051] Weigh 1.8g polyacrylonitrile (PAN), add 15mL N,N-dimethylformamide (DMF), stir in a 60°C water bath for 3h, then add 5g ammonium molybdate, stir for 1h, control voltage 11kV, indirect The collection distance is 15cm, the liquid flow rate is 30μl / min, and the PAN / ammonium molybdate hollow fiber is obtained through the electrospinning process. The obtained composite fibers were put into a tube furnace and pretreated at 250°C for 1 h. Under an ammonia atmosphere, the nitriding temperature is 800°C, and the heating rate is 3°C / min, the hollow composite fiber is nitrided to obtain the hollow carbon / molybdenum nitride composite fiber. The obtained material was mixed with KOH in a ratio of 1:4, and chemically activated at 800° C. for 2 hours under the protection of argon to obtain porous hollow carbon / molybdenum nitride fibers.

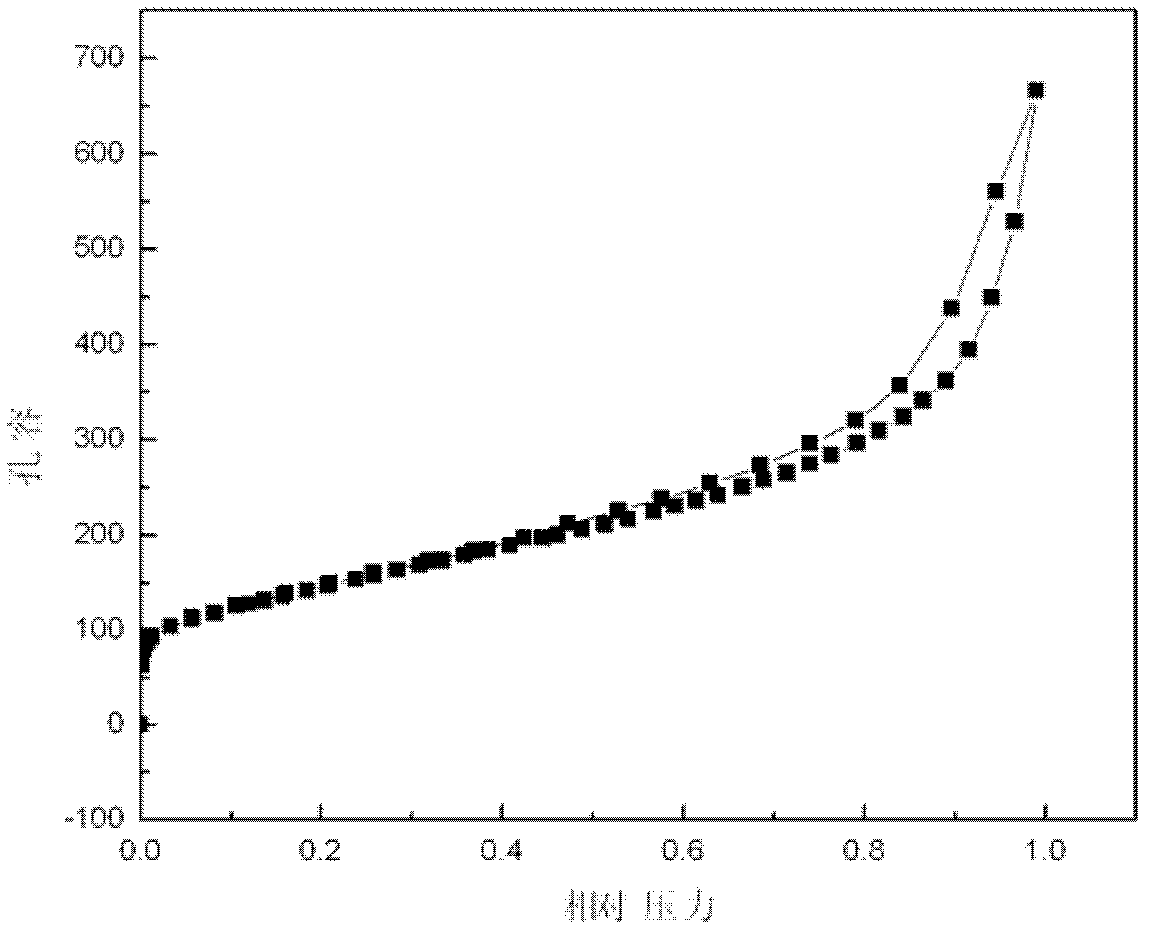

[0052] Pole sheet preparation and battery assembly are the same as the test and Example 1. The specific surface area of the positive electrode ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com