Multilayer thin film OTFT (organic thin film transistor) formaldehyde gas sensor and preparation method thereof

A technology of formaldehyde sensor and multi-layer thin film, which is applied in the direction of coating, instrument, scientific instrument, etc., can solve the problems of poor stability and repeatability, slow response time, poor selectivity, etc., achieve low cost, improve device performance, and small size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

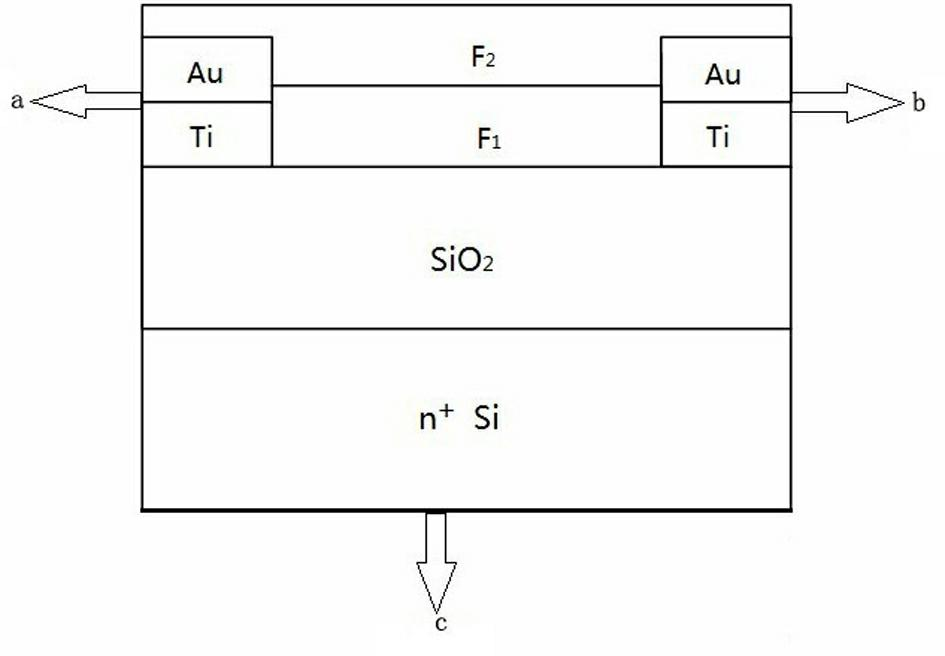

[0041] Multilayer thin film OTFT formaldehyde gas sensor prepared by MEMS technology and thin film, combined with figure 1 As shown, an n-type silicon substrate is taken, and the insulating layer silicon dioxide is prepared by thermal oxidation, gold is used as an electrode, and titanium is used as a transition layer. The electrode layer is located on the transition layer for the purpose of enhancing adhesion. The source a, The drain b and gate c three-terminal electrodes respectively have external leads for testing. The invention utilizes the characteristics of the OTFT sensor structure itself, and directly adopts the method of sintering the conductive glue on the silicon chip substrate to lead out the grid, which greatly simplifies the preparation process and improves the performance of the device.

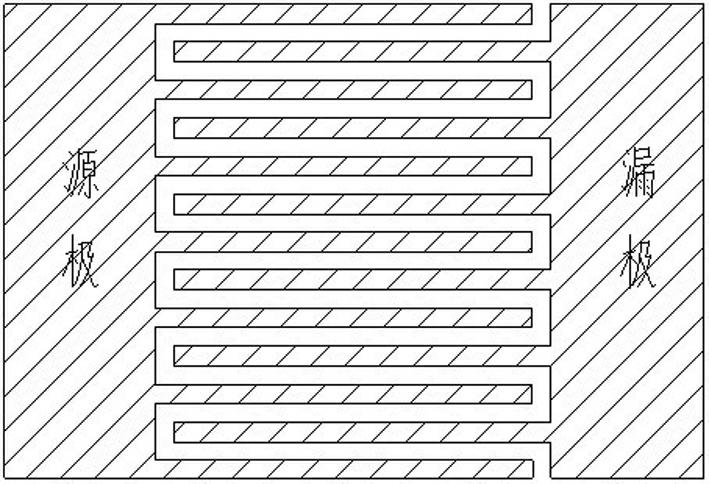

[0042] combine figure 2 Shown is the gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com