Ball body of rupture-preventing heavy-caliber composite ceramic ball valve, composite ceramic ball valve and manufacture methods thereof

A composite ceramic and large-diameter technology, which is applied in valve details, valve devices, and valve housing structures, can solve problems such as low internal density, difficulty in realizing ceramic ball valves, and incomplete sintering, and achieve simplification of production process and torque distribution. Uniform, production-controlled improved results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

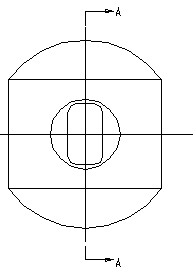

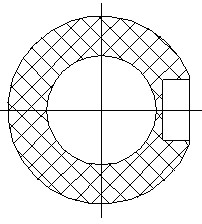

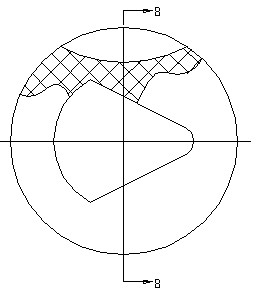

[0027] Such as Figure 3-8 The shown anti-cracking large-diameter composite ceramic ball valve is assembled from a ceramic cylinder 14, a metal ring 11, a left ceramic spherical cap 12 and a right ceramic spherical cap 13. The metal ring 11 is on the outer wall of the ceramic cylinder 14 and in the middle of the ceramic cylinder. The metal ring 11 and the ceramic cylinder 14 are combined by a heat-fitting process or an adhesive process. The left and right ceramic spherical caps are inserted into the outside of the ceramic cylinder and moved to the center line to cover the metal ring. The end faces of the left and right ceramic spherical caps are tightly fitted. It is filled with high-temperature and high-strength glue and bonded firmly. On the metal ring 11, an arc groove matching the valve stem 10 or an elliptical hole is milled out. The ceramic cylinder 14 is a zirconia ceramic cylinder or an alumina-toughened zirconia composite. The materials of the ceramic cylinder, the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com