High-conductivity non-heat-treatment type moderate-intensity aluminum alloy wire and production method thereof

A medium-strength aluminum alloy, non-heat treatment technology, applied in the field of electrical material manufacturing, can solve the problems of uneven heat treatment of aluminum alloy wires, restricting production efficiency and delivery cycle, increasing product cost, etc. Fatigue characteristics, reducing investment in line construction and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: A non-heat-treated medium-strength aluminum alloy wire with high conductivity, characterized in that the weight ratio of raw materials is: Fe: 0.10%, Si: 0.3%, Mg: 0.10%, Cu: 0.05%, Re: 0.5 %, the balance is aluminum and unavoidable trace impurities.

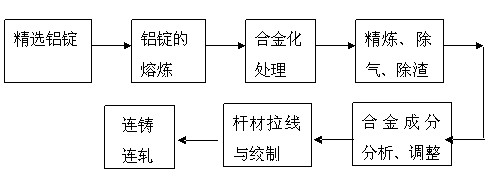

[0025] A method for manufacturing a high-conductivity non-heat-treated medium-strength aluminum alloy wire, characterized by comprising the following steps:

[0026] (1) Selected aluminum ingots: select aluminum ingots with impurity weight percentages of Si≤0.1%, Fe≤0.20%, Cu≤0.01%, Ti+V+Cr+Mn≤0.02%, and other impurities ≤0.03% ;

[0027] (2) Melting of aluminum ingots: Put the aluminum ingots into a vertical melting furnace heated to 800~950°C to melt into molten aluminum, and then transfer them to a holding furnace heated to 750~850°C;

[0028] (3) Alloying treatment: Add Fe: 0.10%, Si: 0.3%, Mg: 0.10%, Cu: 0.05% and Re: 0.5% in the above weight ratio to the molten aluminum as alloying additive elements;

...

Embodiment 2~9

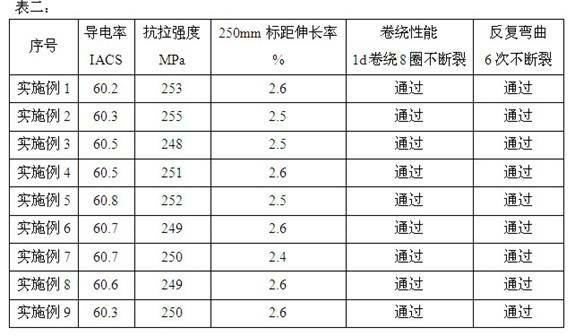

[0034] Examples 2-9, the raw material formula of a high-conductivity non-heat-treated medium-strength aluminum alloy wire is shown in Table 1, the manufacturing method refers to Example 1, and the experimental results of each embodiment correspond to Table 2.

[0035]

[0036]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com