Preparation method and application of phosphorus-halide-cooperation inflaming retarding polyether polyol

A technology of flame retardant polyether and phosphorus halogen synergy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

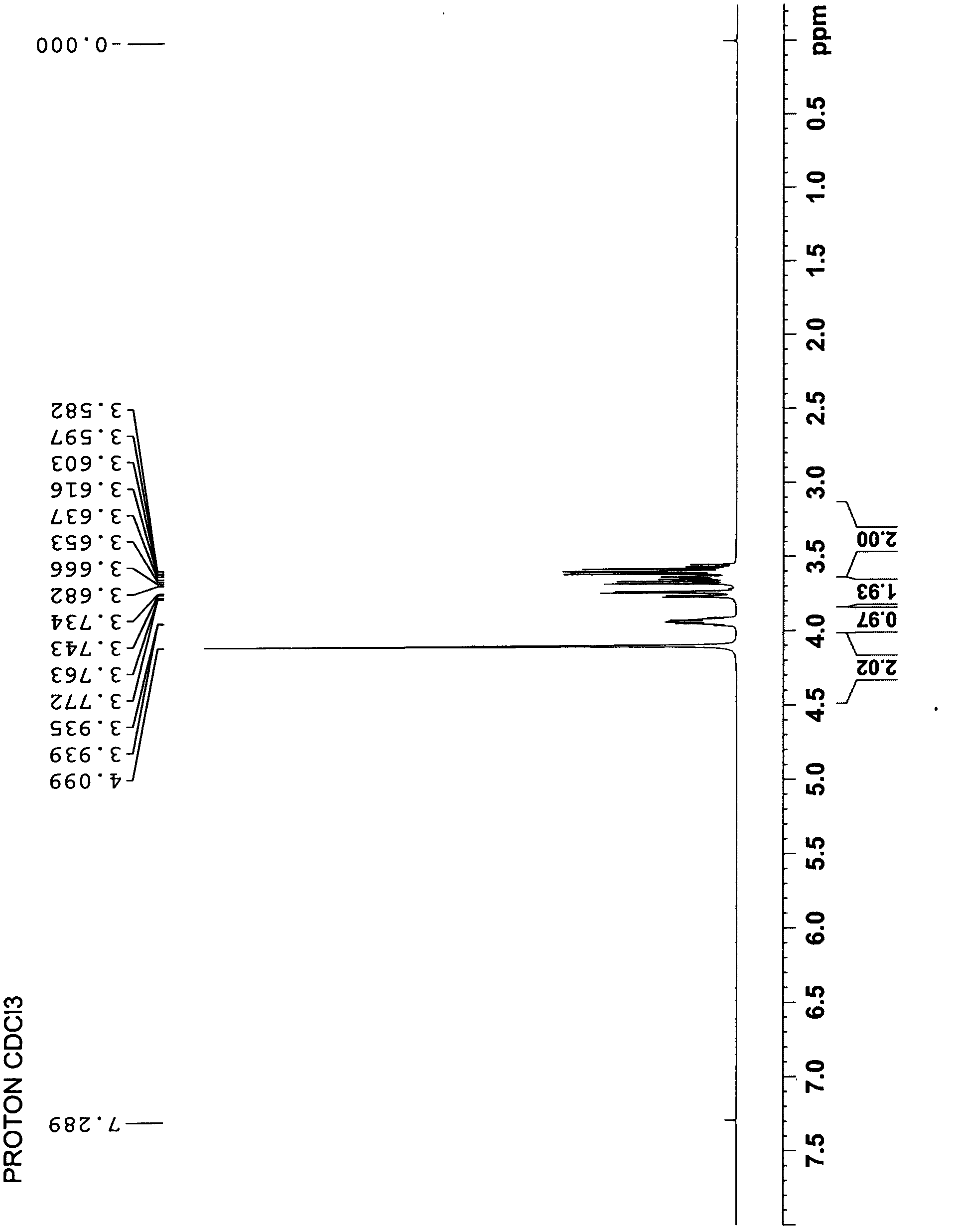

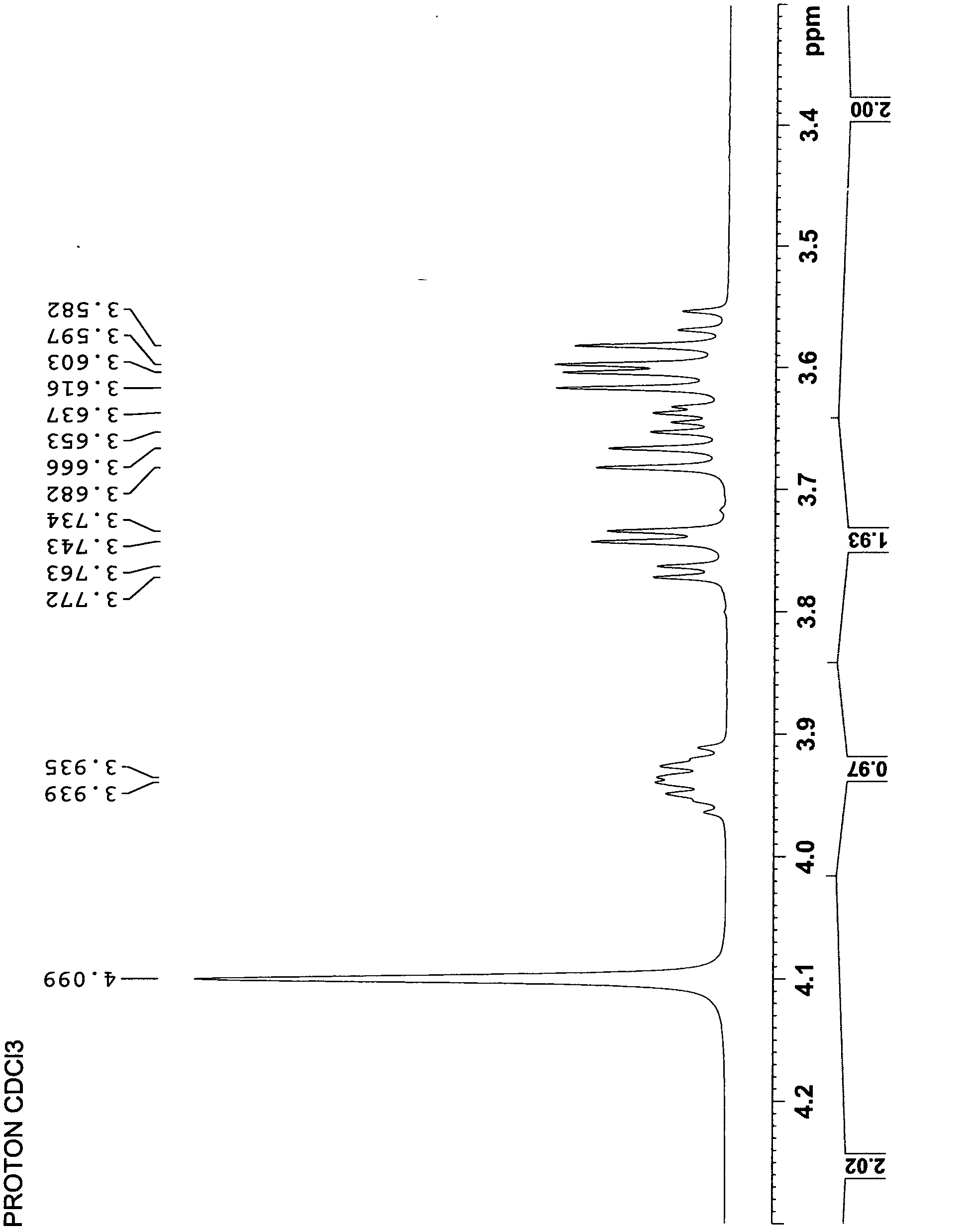

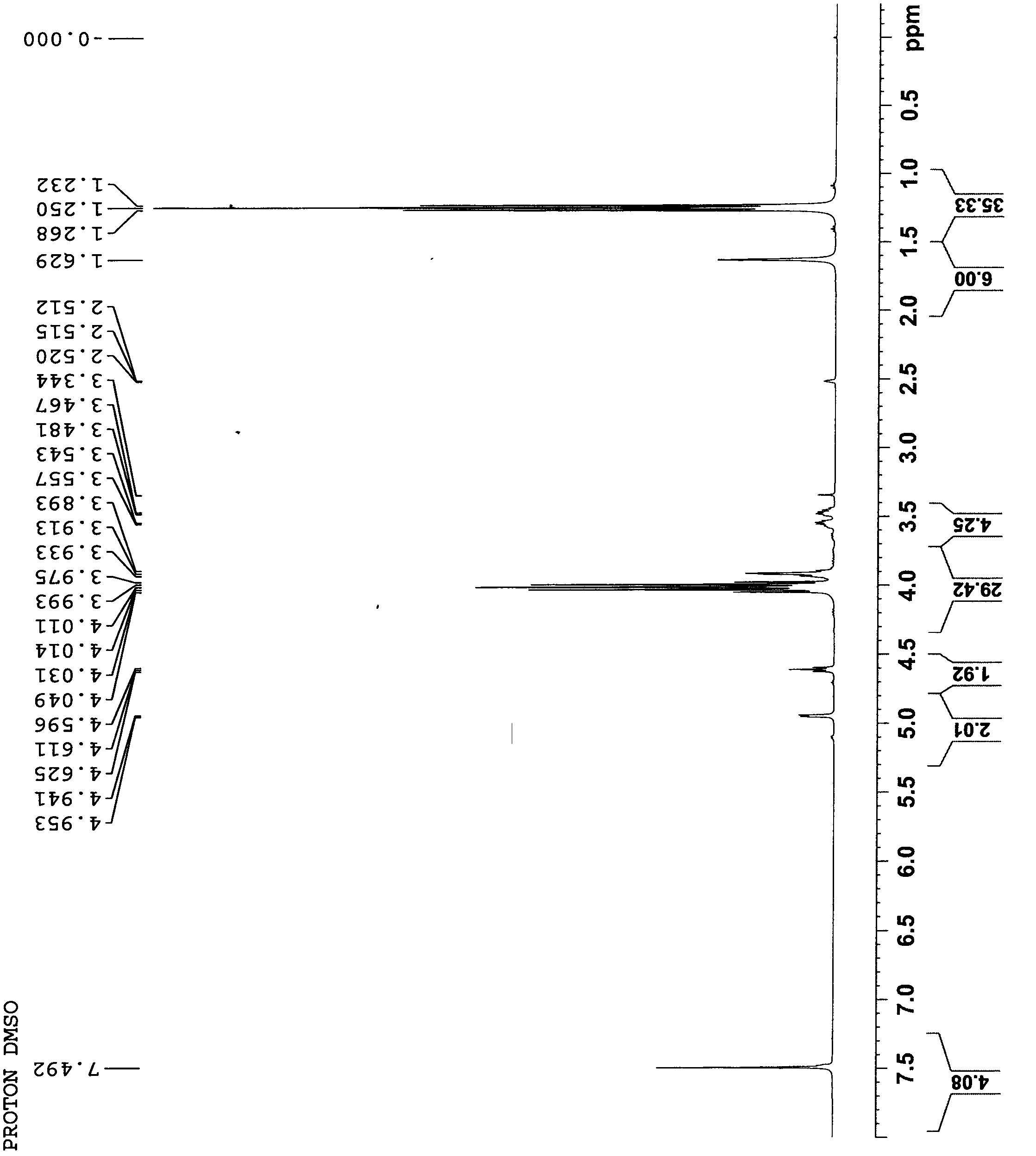

Image

Examples

Embodiment 1

[0054] 1. Weigh 92.5g of epichlorohydrin into a 500mL three-necked flask with a magnetic stirrer, a constant pressure dropping funnel and a thermometer, weigh 0.23g of concentrated sulfuric acid and dissolve it in 144g of water and transfer it to a constant pressure dropping funnel , the inner air of the flask was replaced with nitrogen three times at room temperature, then the temperature was raised to 80° C., and the water containing sulfuric acid was started to be added dropwise.

[0055] 2. Cool down the reaction solution obtained in step 1 to 55-65°C, first use a water pump to remove the water in the system by vacuum distillation under the condition that the vacuum degree is not less than 0.095Mpa, and gradually raise the temperature to 100°C to ensure that the system The water in it is completely removed. Then use an oil pump to further distill under reduced pressure, and heat up to 160 ° C. The collected fraction is the target product 3-chloro-1,2-propanediol (intermedi...

Embodiment 2

[0059] 1. Weigh 92.5g of epichlorohydrin and add it to a 500mL three-neck flask with a magnetic stirrer, constant pressure dropping funnel and thermometer, add 0.9g of ion resin, weigh 180g of water in the constant pressure dropping funnel, and Replace the internal air with nitrogen three times at room temperature, then raise the temperature to 60°C, start to add sulfuric acid water dropwise, and continue to insulate and reflux for 5 hours after the dropwise addition is completed;

[0060] 2. Cool down the reaction solution obtained in step 1 to 55-65°C, first use a water pump to remove the water in the system by vacuum distillation under the condition that the vacuum degree is not less than 0.095Mpa, and gradually raise the temperature to 100°C to ensure that the system The water in it is completely removed. Then use an oil pump to further distill under reduced pressure, and heat up to 160°C. The collected fraction is the target product 3-chloro-1,2-propanediol (intermediate ...

Embodiment 3

[0064] 1. Weigh 92.5g of epichlorohydrin into a 500mL three-neck flask with a magnetic stirrer, constant pressure dropping funnel and thermometer, add 1.8g of aluminum trichloride, weigh 90g of water in the constant pressure dropping funnel , the internal air of the flask was replaced with nitrogen three times at room temperature, then the temperature was raised to 100°C, and water containing sulfuric acid was started to be added dropwise.

[0065] 2. Cool down the reaction solution obtained in step 1 to 55-65°C, first use a water pump to remove the water in the system by vacuum distillation under the condition that the vacuum degree is not less than 0.095Mpa, and gradually raise the temperature to 100°C to ensure that the system The water in it is completely removed. Then use an oil pump to further distill under reduced pressure, and heat up to 160°C. The collected fraction is the target product 3-chloro-1,2-propanediol (intermediate CPG), which is a colorless viscous liquid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com