Composite metal salt catalyst for hydrochlorination reaction of acetylene

A composite metal salt, acetylene hydrochlorination technology, applied in physical/chemical process catalysts, organic chemistry, hydrogen halide addition preparation, etc. The effect of enhancing activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

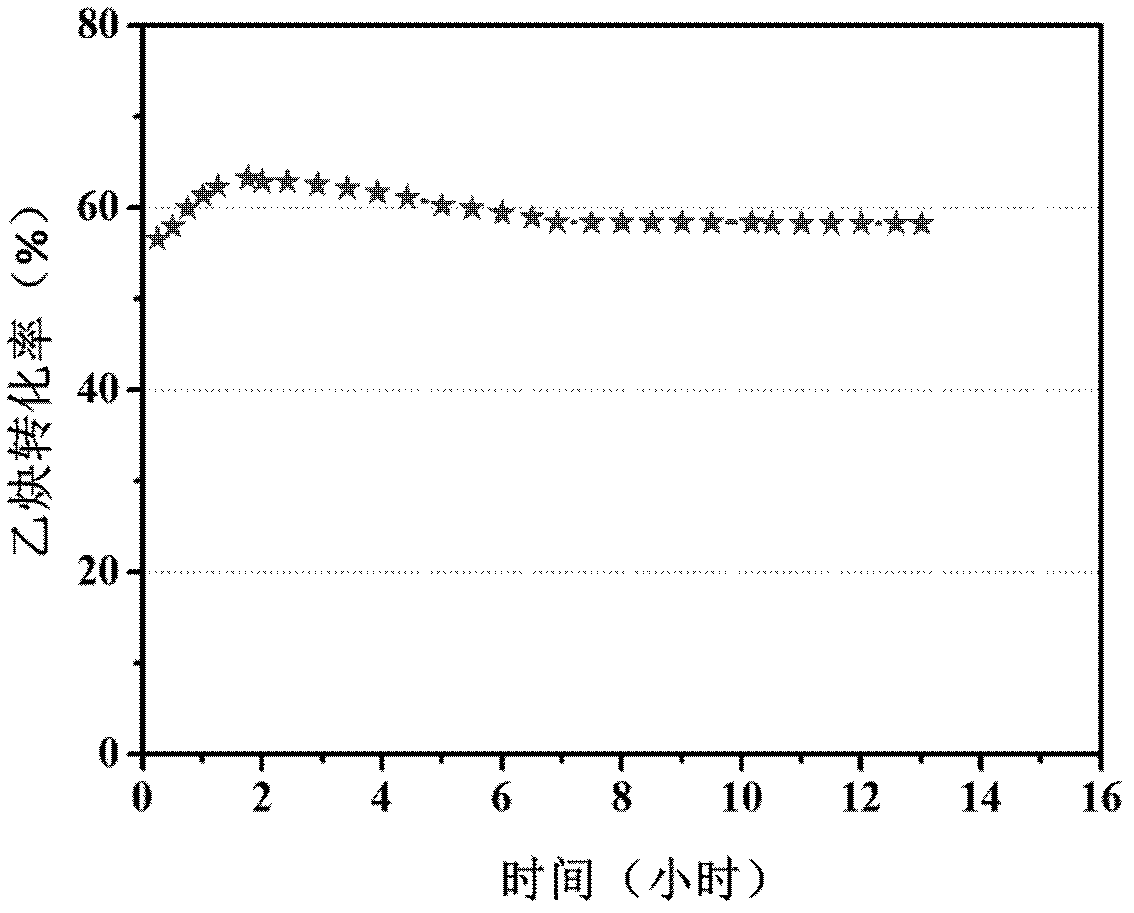

[0035] A catalyst prepared with coconut shell charcoal as a carrier, chloroauric acid and cupric chloride as active component precursors, wherein the loading amount of gold is 0.25%. The micro-reaction evaluation conditions are as follows:

[0036] Reaction temperature: 180°C; Reaction pressure: normal pressure; Reaction space velocity: 1200h -1 (volume space velocity, acetylene metering); hydrogen chloride flow / acetylene flow=1.1:1.0. The conversion and selectivity of the catalyst are as follows figure 1 , Table 1 shows.

Embodiment 2

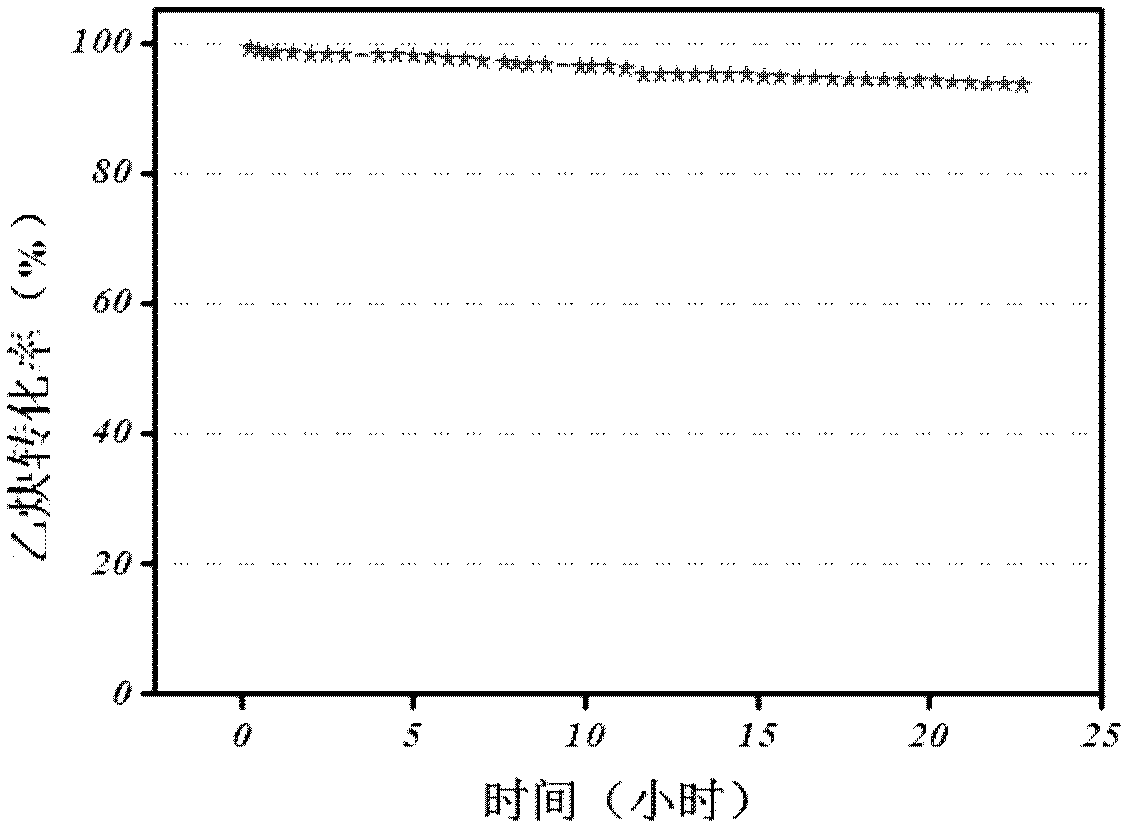

[0038] Coconut shell charcoal is used as a carrier, chloroauric acid and copper chloride are used as active component precursors, and cerium chloride is used as a catalyst prepared by adding auxiliary agents, wherein the loading amount of gold is 0.25%. The micro-reaction evaluation conditions are as follows:

[0039] Reaction temperature: 180°C; Reaction pressure: normal pressure; Reaction space velocity: 360h -1 (volume space velocity, acetylene metering); hydrogen chloride flow / acetylene flow=1.1:1.0. The conversion and selectivity of the catalyst are as follows figure 2 , Table 1 shows.

Embodiment 3

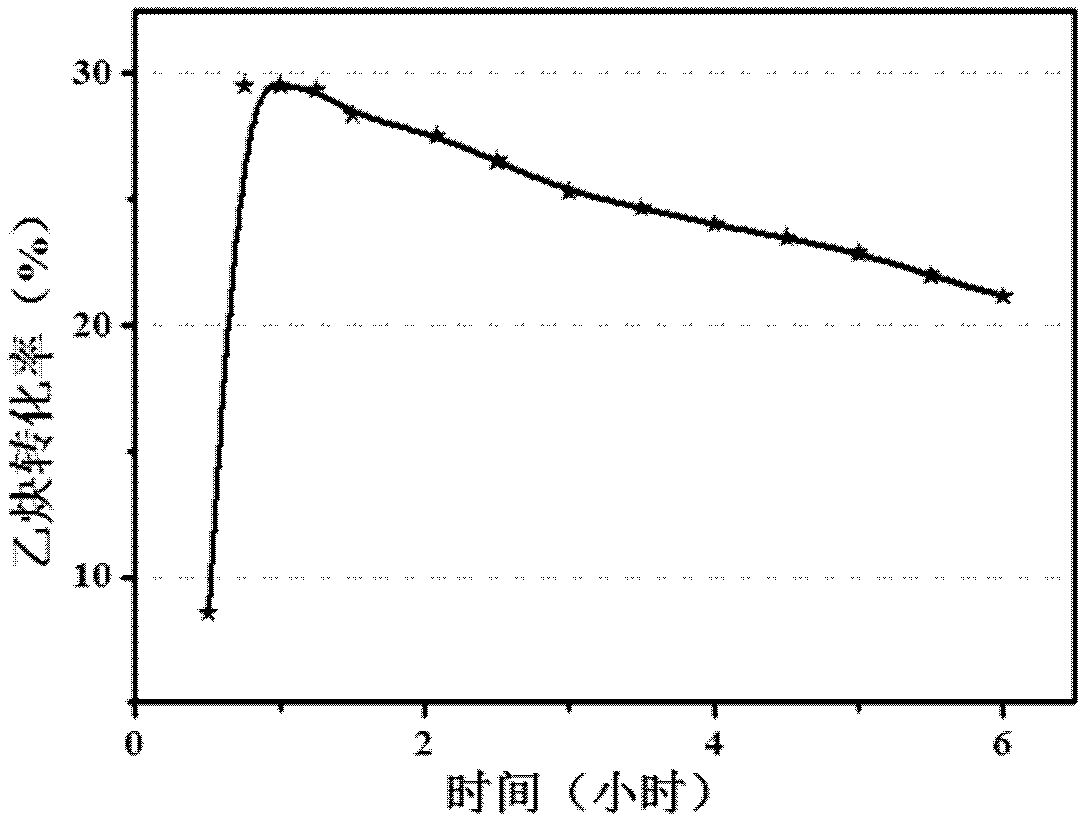

[0041]Carbon nanotubes are used as the carrier, chloroauric acid is used as the precursor of the active component, and the loading amount of Au is 0.10%. The micro-reaction evaluation conditions are as follows:

[0042] Reaction temperature: 180°C; Reaction pressure: normal pressure; Reaction space velocity: 1200h -1 (volume space velocity, acetylene metering); hydrogen chloride flow / acetylene flow=1.1:1.0. The conversion and selectivity of the catalyst are as follows image 3 , Table 1 shows.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com