Method for synthesizing coating printing thickening agent

A technology of pigment printing and synthesis method, which is applied in the field of chemical synthesis and fabric printing additive synthesis, which can solve the problems of application limitation of acrylic inverse emulsion thickener and achieve high thickening ability and high anti-seepage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

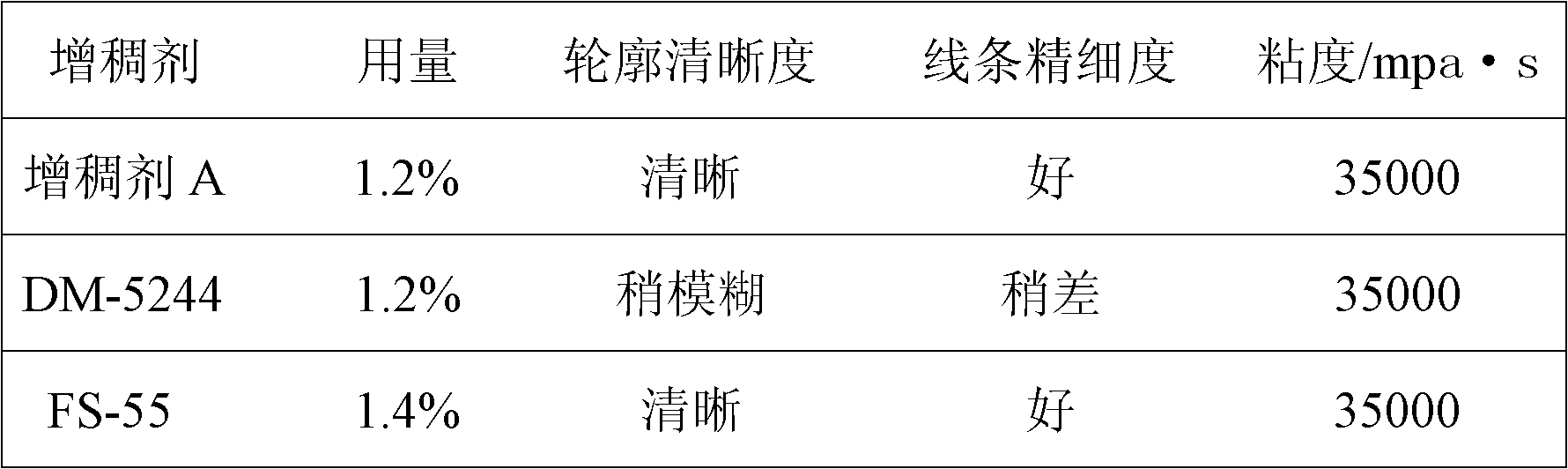

Image

Examples

preparation example Construction

[0013] Preparation steps of the present invention are:

[0014] Include the following steps:

[0015] (1) Polyurethane prepolymer preparation, take the polyether glycol 5-25 weight part of dehydration, 1,4-butanediol 2-7 weight part and toluene diisocyanate 20-40 weight part, in 70-100 ℃ for 2-4 hours, then lower the temperature to below 40 ℃, add 2-6 parts by weight of triethylamine to neutralize the pH value to 7, and add 0.15-1 part by weight of ethylenediamine under high-speed shearing to prepare polyurethane pre- Polymers; high-speed shearing generally requires a shearing speed greater than 1000 rpm.

[0016] (2) preparation of polyurethane-polyacrylic acid composite emulsion, adding in the prepolymer prepared in step (1): 40-80 parts by weight of acrylic acid, 10-20 parts by weight of acrylamide, 10-20 parts by weight of ethyl methacrylate and 0.1-0.3 parts by weight of ammonium persulfate, reacted at 30-90° C. for 1-3 hours, and then vacuumized to remove acetone to pr...

Embodiment 1

[0020] Weigh 5 parts by weight of dehydrated polyether diol, 2 parts by weight of 1,4-butanediol and 20 parts by weight of toluene diisocyanate, react at 70°C for 2 hours, then cool down to 40°C, add 2 parts by weight of triethylamine 0.15 parts by weight of ethylenediamine under high-speed shearing to obtain a polyurethane prepolymer;

[0021] Add to the prepolymer prepared above: 40 parts by weight of acrylic acid, 10 parts by weight of acrylamide, 10 parts by weight of ethyl methacrylate, 0.1 part by weight of ammonium persulfate, react at 30°C for 1 hour, and then vacuumize and remove In addition to acetone, the polyurethane-polyacrylic acid composite emulsion is obtained;

[0022] Ammonia water is added dropwise to the above compound emulsion, and the pH value of the emulsion is adjusted to 5.0, thereby preparing a novel pigment printing thickener with high thickening ability and high anti-seepage effect.

Embodiment 2

[0024] Weigh 25 parts by weight of dehydrated polyether diol, 7 parts by weight of 1,4-butanediol and 40 parts by weight of toluene diisocyanate, react at 100°C for 4 hours, then cool to 20°C, add triethylamine 6 Parts by weight are neutralized, and 1 part by weight of ethylenediamine is obtained under high-speed shear to obtain a polyurethane prepolymer;

[0025] Add to the prepolymer prepared above: 80 parts by weight of acrylic acid, 20 parts by weight of acrylamide, 20 parts by weight of ethyl methacrylate, 0.3 parts by weight of ammonium persulfate, react at 90°C for 3 hours, and then vacuumize and remove In addition to acetone, the polyurethane-polyacrylic acid composite emulsion is obtained;

[0026] Ammonia water is added dropwise to the above composite emulsion, and the pH value of the emulsion is adjusted to 6.0, thereby preparing a new type of pigment printing thickener with high thickening ability and high anti-seepage effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com