Antifogging agent composition and transparent antifogging window membrane formed therefrom

A technology of anti-fogging agent and composition, applied in the direction of synthetic resin layered products, adhesives, film/sheet adhesives, etc., can solve the problems of large waste of resources, poor anti-fog durability, high price, etc., and achieve production costs Low, easy to operate, with high light transmittance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

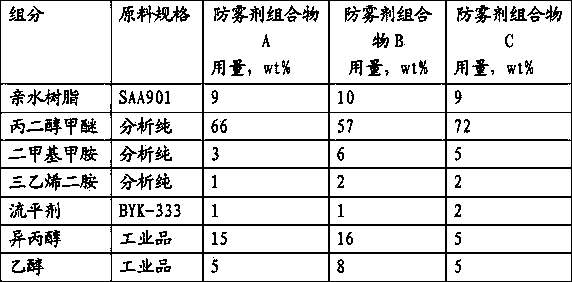

[0037] Embodiment 1 Preparation of antifogging agent compositions A~C

[0038] ① Formula

[0039] The specific formula is shown in Table 1.

[0040] Table 1

[0041]

[0042] Note 1: SAA901 is the product brand of hydrophilic resin of Xi'an Aerospace Sanwo Chemical Co., Ltd.; propylene glycol methyl ether, dimethylmethylamine, and triethylenediamine are all products of Shanghai Experimental Reagent Co., Ltd.; BYK-333 is German BYK Chemicals The company's product grade; isopropanol and ethanol are from Changzhou Yuanxing Chemical Co., Ltd.;

[0043] Note 2: SAA901 product performance: the appearance is a colorless transparent liquid, the composition is hydrophilic acrylate

[0044] Oligomer-like, the solid content is 44.5±1wt% (measured at 150°C), and the viscosity is 5±0.5cps / 25°C.

[0045] ② preparation

[0046] Weigh each component according to the formula amount in Table 1, put them into a container, stir and mix evenly at room temperature to prepare antifogging age...

Embodiment 2

[0048] Example 2 Preparation of transparent anti-fog window film

[0049] The specific operation is as follows:

[0050] (A) Prepare raw materials

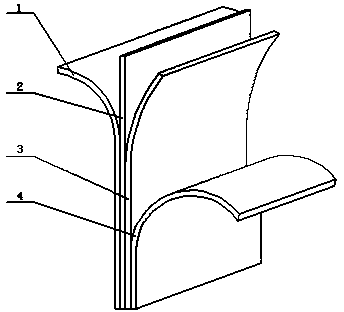

[0051] ① Prepare a transparent polyester film substrate 2 with a thickness of 50 μm; a release film 4 with a thickness of 23 μm;

[0052] ② Prepare the antifogging agent composition A obtained in Example 1;

[0053] ③Prepare the mixed material forming the acrylic adhesive layer 3

[0054]According to the mass ratio of acrylic adhesive: curing agent: methyl ethyl ketone: toluene is 10: 0.13: 5: 3 to prepare the above-mentioned components. After stirring for 12 to 18 minutes, add curing agent and stir for 18 to 22 minutes, measure the viscosity as 80 to 300 centipoise, and store it for later use;

[0055] Among them, the acrylic adhesive is SAA1401 produced by Xi'an Aerospace Sanwo Chemical Co., Ltd., and its solid content is 40wt%-45wt%. The curing agent is SAC12 produced by Xi'an Aerospace Sanwo Chemical Co., Ltd., and its sol...

Embodiment 3

[0061] Example 3 Preparation of transparent anti-fog window film

[0062] The specific operation is as follows:

[0063] (A) Prepare raw materials

[0064] ① Prepare a transparent polyester film substrate 2 with a thickness of 50 μm; a release film 4 with a thickness of 39 μm;

[0065] ② Prepare the antifogging composition B prepared in Example 1;

[0066] ③Prepare the mixed material forming the acrylic adhesive layer 3

[0067] Prepare the above components according to the mass ratio of acrylic adhesive: curing agent: butanone: toluene: 10:0.15:6:4, and mix the butanone, toluene and acrylic adhesive evenly at the ambient temperature of 18-28°C After stirring for 12 to 18 minutes, add curing agent and stir for 18 to 22 minutes, measure the viscosity to 80 to 300 centipoise, and store it for later use;

[0068] Among them, the acrylic adhesive is WA-240 produced by Shanghai Kailanda Industrial Co., Ltd., and its solid content is 40wt%-45wt%. The curing agent is KS-05 produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com