UV antifogging coating for protective mask and preparation method of UV antifogging coating

A technology for protective masks and anti-fog coatings, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of mirror fogging, affecting user experience, blocking vision, etc., achieves rapid curing, excellent surface anti-fog performance, and reduces cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

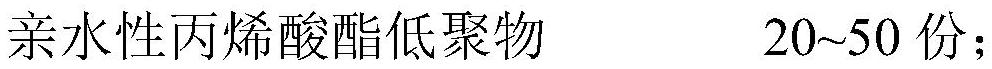

[0031] A kind of UV anti-fog paint for protective mask, its component and mass parts are as follows:

[0032]

[0033] In this embodiment, the hydrophilic acrylate oligomer is selected from polyurethane acrylate oligomer, the hydrophilic reactive diluent is selected from ethoxylated trimethylolpropane triacrylate (15EO-TMPTA), and the reactive diluent The agent is dipentaerythritol hexaacrylate, the photoinitiator is initiator 2959, the solvent is ethyl acetate, and the leveling agent is BYK-333.

[0034] The protective mask is obtained by the following method with UV anti-fog coating:

[0035] Put the hydrophilic acrylate oligomer, hydrophilic reactive diluent, high-functional reactive diluent, solvent, and photoinitiator into the reactor in turn, stir at 400 rpm for 25 minutes, then reduce the speed to 150 rpm, and then add the leveling agent. Stir for 10 minutes, adjust the viscosity, let it stand for 12 minutes, and filter to obtain the UV anti-fog coating for protecti...

Embodiment 2

[0037] A kind of UV anti-fog paint for protective mask, its component and mass parts are as follows:

[0038]

[0039] In this embodiment, the hydrophilic acrylate oligomer is selected from polyurethane acrylate oligomer, the hydrophilic reactive diluent is selected from ethoxylated trimethylolpropane triacrylate (15EO-TMPTA), and the reactive diluent The agent is dipentaerythritol hexaacrylate, the photoinitiator is initiator 2959, the solvent is ethyl acetate, and the leveling agent is BYK-333.

Embodiment 3

[0041] A kind of UV anti-fog paint for protective mask, its component and mass parts are as follows:

[0042]

[0043] In this embodiment, the hydrophilic acrylate oligomer is selected from polyurethane acrylate oligomer, the hydrophilic reactive diluent is selected from ethoxylated trimethylolpropane triacrylate (15EO-TMPTA), and the reactive diluent The agent is dipentaerythritol hexaacrylate, the photoinitiator is initiator 2959, the solvent is ethyl acetate, and the leveling agent is BYK-333.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com