Preparation method of Ni-P alloy lithium ion battery cathode material of core-shell structure

A lithium-ion battery, core-shell structure technology, applied in battery electrodes, structural parts, circuits, etc., can solve the problems of hidden dangers of reaction safety, complicated preparation process, cumbersome methods, etc., and achieves low equipment requirements, high solution purity, and reaction. Conditional effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

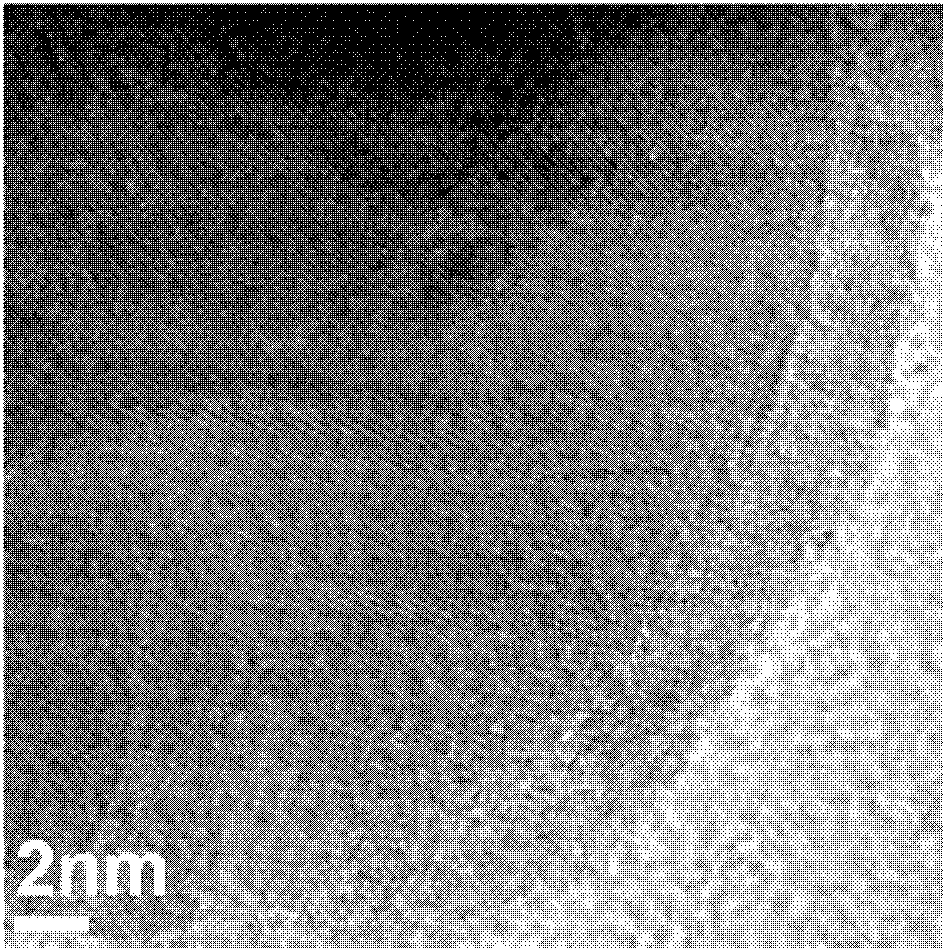

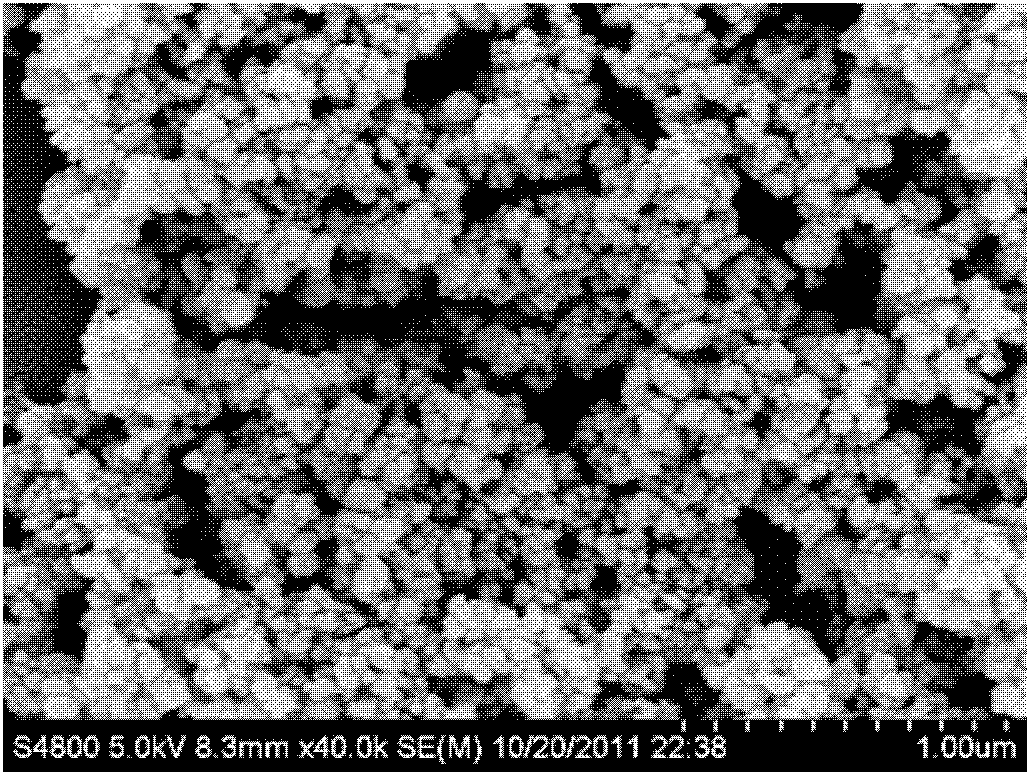

[0023] Add 27g of choline chloride (purchased from Aladdin Reagent (Shanghai) Co., Ltd.), 13g of ethylene glycol and 15g of propylene glycol into a three-necked flask, stir and mix at 120°C to obtain a mixed solution, about 50ml. 0.2594gNiCl 2 and 0.1681gNH 4 h 2 PO 2 Sequentially added to the mixed solution, ultrasonically dissolved for 1 h to obtain a reaction precursor solution. Afterwards, the reflux device was connected, and the reaction precursor solution was heated to 90° C. under normal pressure. After reacting for 2 hours, the three-necked bottle was removed and immediately quenched with cold water. Ultrasonic disperse the obtained precipitate in a three-necked bottle for 30 minutes, then transfer it to a centrifuge tube for centrifugation, and then alternately wash the obtained precipitate with methanol and deionized water, and dry it in a vacuum oven at 60°C after cleaning. After 8 hours, black solid powder Ni-P alloy lithium ion battery negative electrode mater...

Embodiment 2

[0026] Add 27g of choline chloride (purchased from Aladdin Reagent (Shanghai) Co., Ltd.), 13g of ethylene glycol and 15g of propylene glycol into a three-necked flask, stir and mix at 120°C to obtain a mixed solution, about 50ml. 1.9454gNiCl 2 and 3.7352gNH 4 h 2 PO 2 Sequentially added to the mixed solution, ultrasonically dissolved for 1.5 h to obtain a reaction precursor solution. Afterwards, the reflux device was connected, and the reaction precursor solution was heated to 180°C under normal pressure. After reacting for 4 hours, the three-necked bottle was removed and immediately quenched with cold water. The obtained precipitate was ultrasonically dispersed in a three-necked bottle for 30 minutes, then transferred to a centrifuge tube for centrifugation, and then washed with methanol and deionized water alternately, and dried in a vacuum oven at 60°C for 8 Hour, obtain black solid powder Ni-P alloy lithium ion battery negative electrode material.

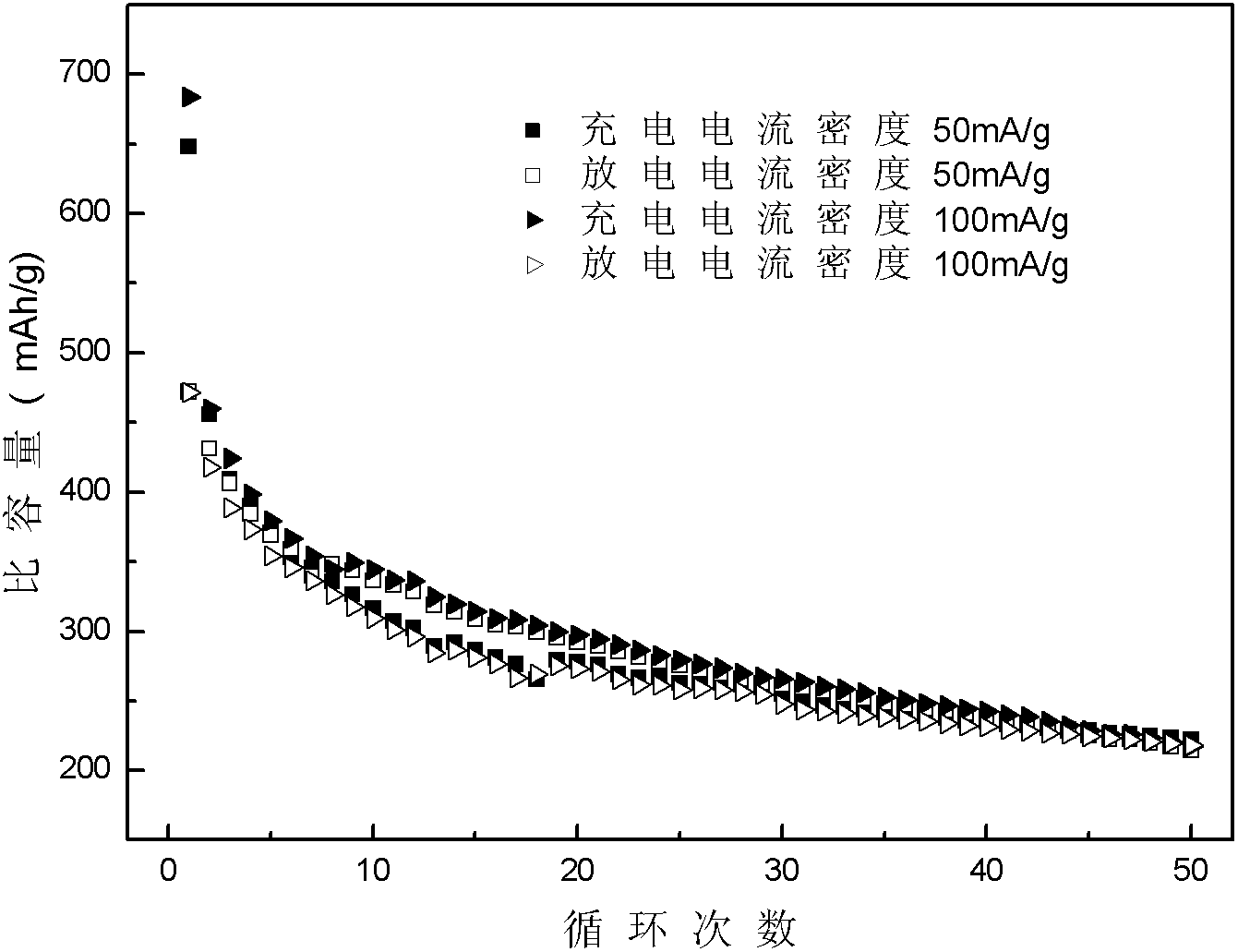

[0027] The negativ...

Embodiment 3

[0029] Add 27g of choline chloride, 17g of ethylene glycol and 20g of propylene glycol into a three-necked flask, stir and mix at 120°C to obtain a mixed solution, about 60ml. 3.2423gNiCl 2 and 4.1515gNH 4 h 2 PO 2 Sequentially added to the mixed solution and ultrasonically dissolved for 2 hours to obtain a reaction precursor solution. Afterwards, the reflux device was connected, and the reaction precursor solution was heated to 210°C under normal pressure. After reacting for 5 hours, the three-necked bottle was removed and immediately quenched with cold water. The obtained precipitate was ultrasonically dispersed in a three-necked bottle for 50 minutes, then transferred to a centrifuge tube for centrifugation, and then washed with methanol and deionized water alternately, and dried in a vacuum oven at 80°C for 8 Hour, obtain black solid powder Ni-P alloy lithium ion battery negative electrode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com