Equipment for synchronously producing multiple fiber insulating sleeves with ultraviolet light curing technology

A curing technology, insulating sleeve technology, applied in insulators, electrical components, circuits, etc., can solve problems such as unfavorable efficiency, low cost performance, and improvement, and achieve the effect of improving quality and saving coating materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

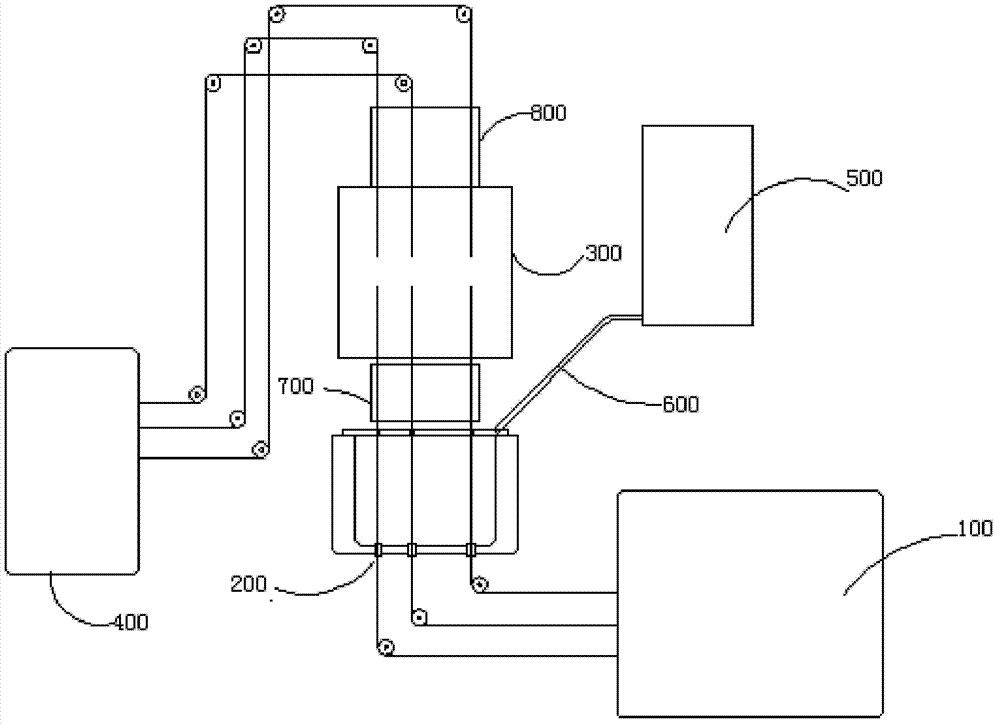

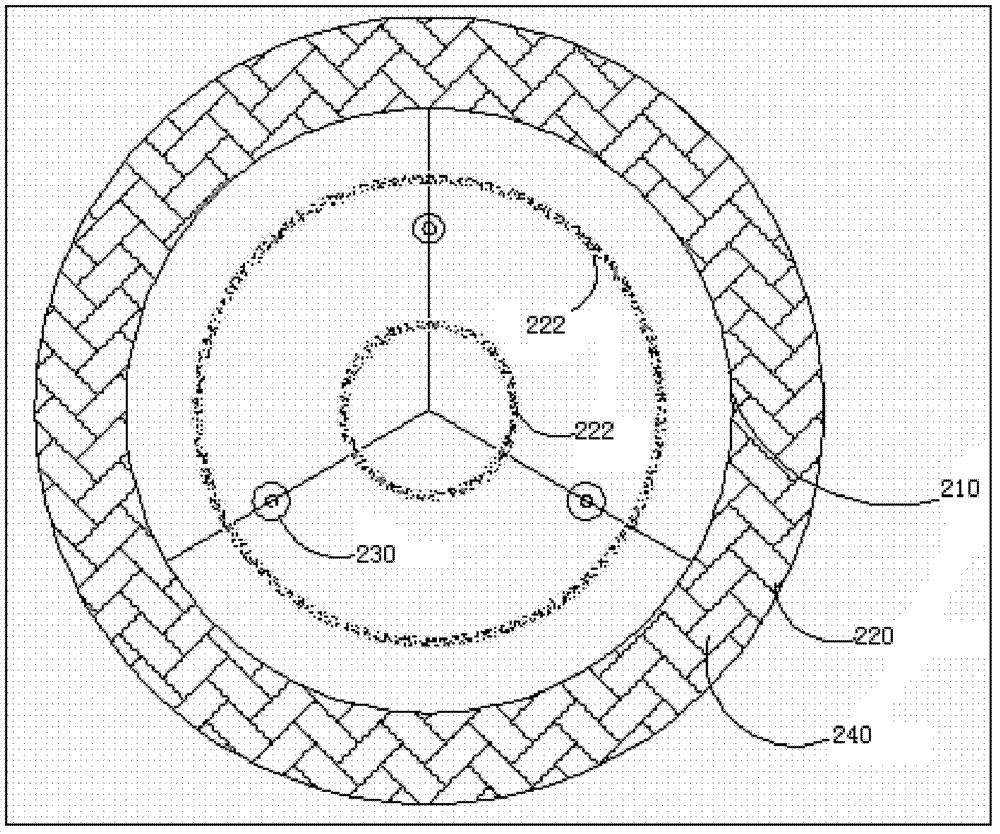

[0016] like figure 1 As shown, the present invention includes a blank tube guiding device 100 , a coating device 200 , a light source system 300 , a sleeve pulling device 400 , and a resin mixing and preheating tank 500 . The blank tube guiding device 100 is located at the forefront, and the coating device 200 is arranged behind it, the light source system 300 is located directly above the coating device 200, the sleeve pulling device 400 is located at the rear of the coating device 200, and the resin mixing and preheating tank 500 It is located obliquely above the coating device 200 and communicates with the coating device 200 through the feed pipe 600 to ensure continuous supply of photocurable coating.

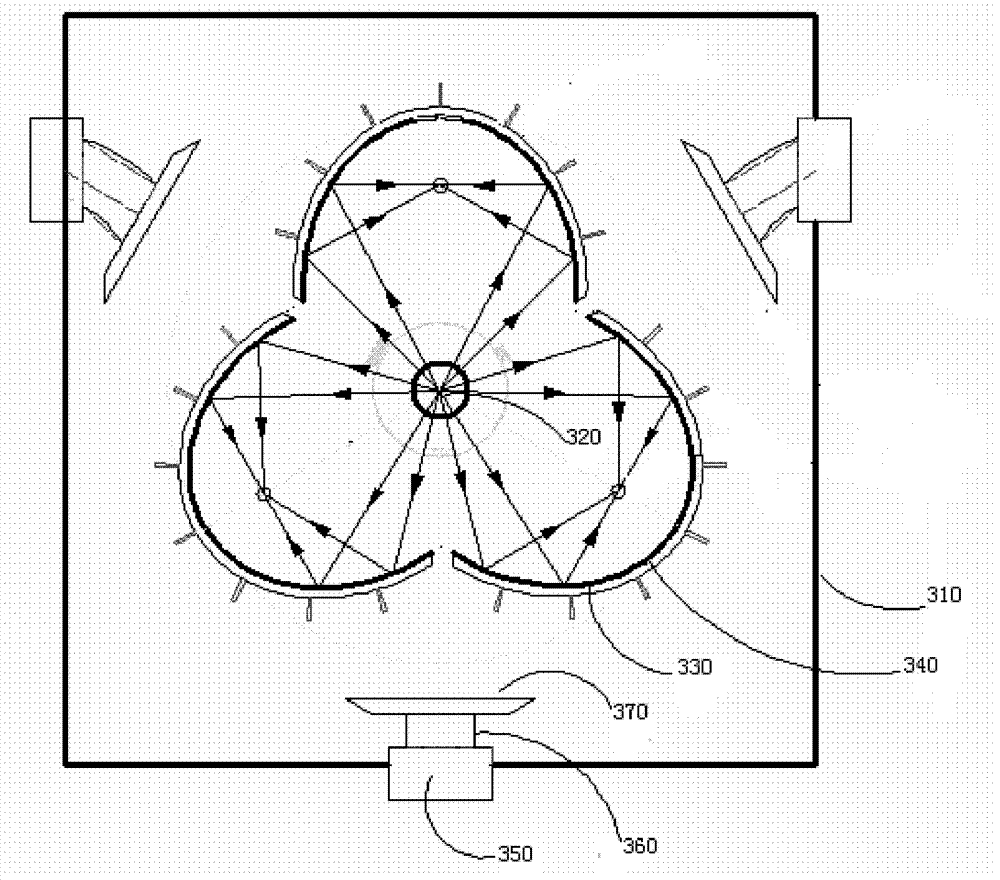

[0017] like figure 2 As shown, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com