Heavy-metal chromium form separating method

A separation method and heavy metal technology are applied in the field of environmental analysis to achieve the effects of wide source, obvious adsorption effect and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

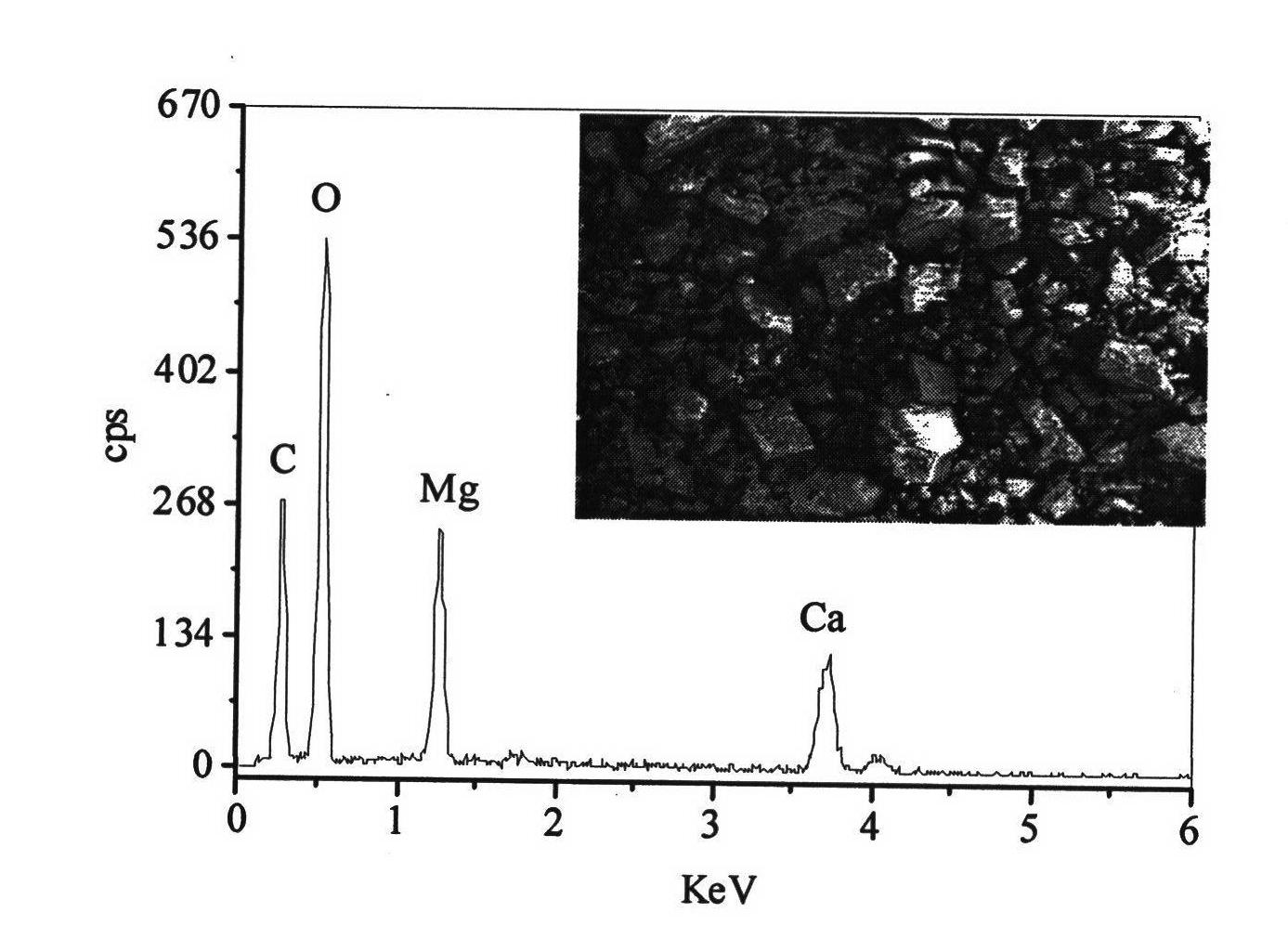

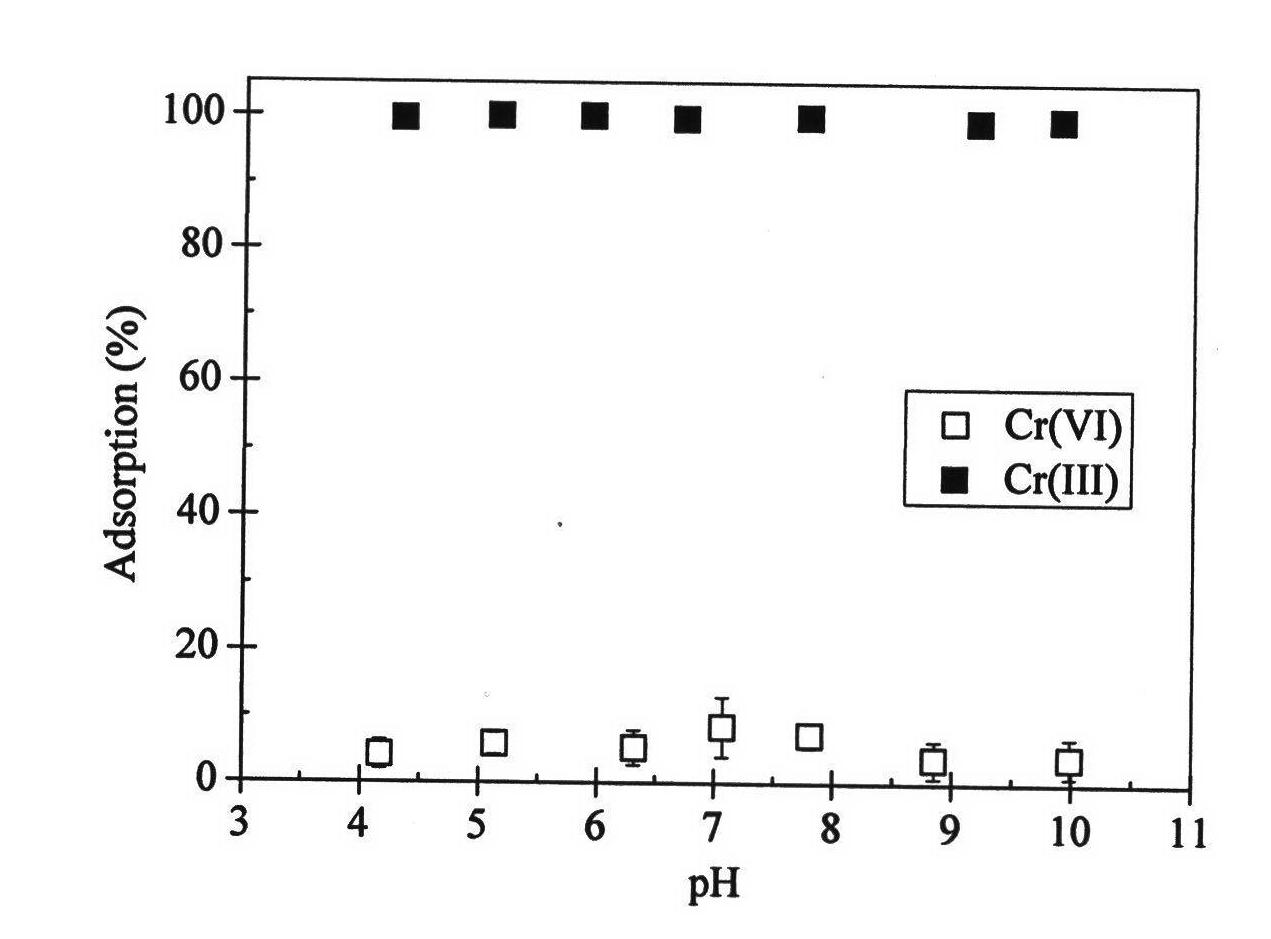

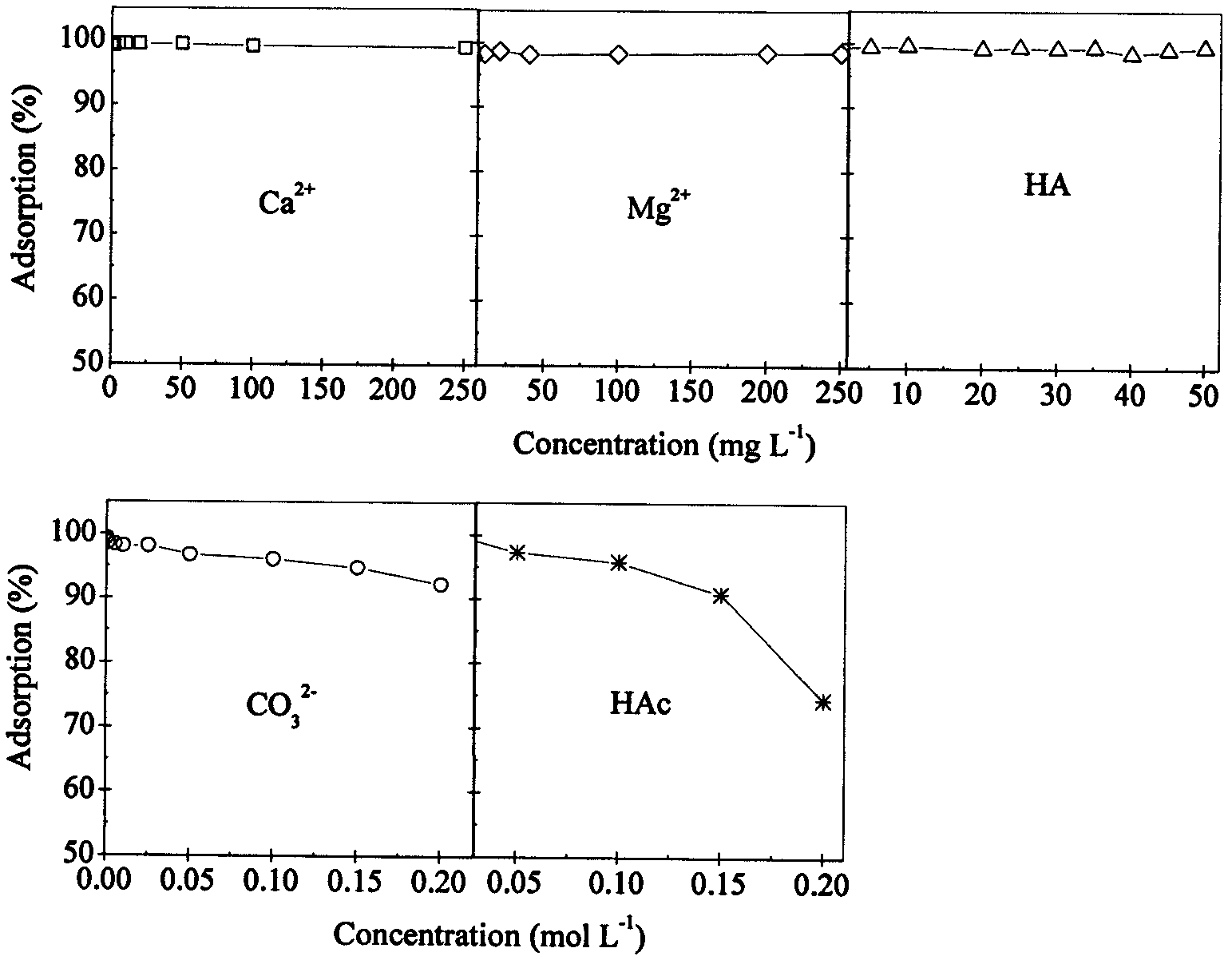

Image

Examples

Embodiment 1

[0021] Example 1 Add 30 μg / L Cr(III) and 20 μg / LCr(VI) to tap water, well water and river water respectively, and only add 1000 μg / L Cr(III) to electroplating wastewater and chromium slag extract. Use dolomite to separate Cr(III) and Cr(VI) from the above actual water samples: take 12mL water samples respectively, and absorb them in SPE cartridges with 4g dolomite at a flow rate of 0.7mL / min. The concentration of total Cr before adsorption (that is, the concentration of Cr(III) and Cr(VI) included in Total Cr) and the concentration of Cr(III) after adsorption were measured by graphite furnace atomic absorption spectrometry (GFAAS). Then use a spectrophotometer to detect the concentration of Cr(VI) after adsorption at a wavelength of 540 nm. The result of the experiment was that Cr(III) was not detected after adsorption, but the amount of Cr(VI) measured was consistent with that before adsorption (Table 1). Therefore, this example illustrates that the present invention has a r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com