Light source preparation method for nondispersive spectrum gas analysis instrument

A gas analyzer, non-dispersive technology, applied in the direction of transmittance measurement, etc., can solve the problems of low detection sensitivity, poor signal-to-noise ratio of the system, etc., and achieve the effects of high thermal conductivity, low heat loss, and low thermal residence characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

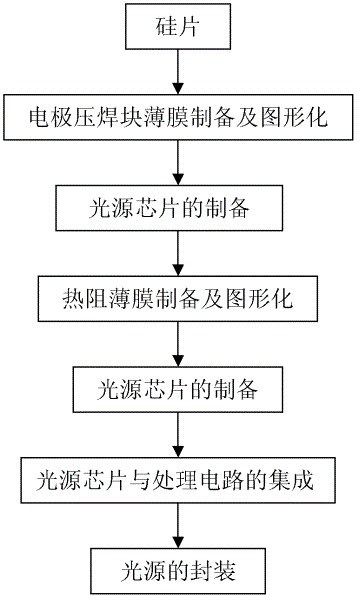

[0022] A method for preparing a light source for a non-dispersive spectroscopic gas analyzer, such as figure 1 As shown, the specific implementation steps of this method are as follows:

[0023] Step 1: preparing a thermal insulation film on the substrate;

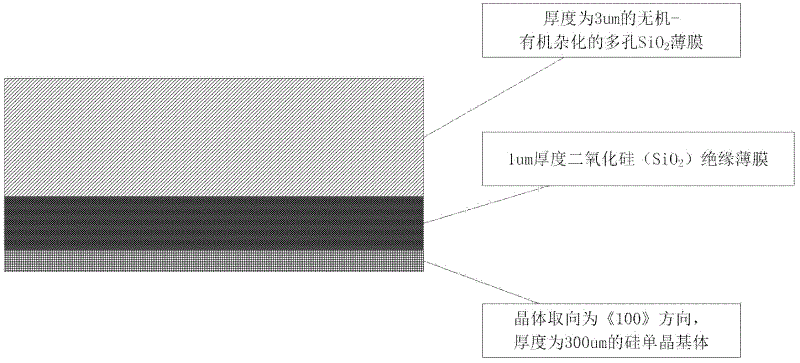

[0024] Using the silicon single crystal coated with a silicon dioxide insulating film on the surface as the substrate, a layer of inorganic-organic hybrid porous SiO was prepared according to the method described in the patent application number 201010257991.3: A thermal insulation structure film preparation 2 film;

[0025] The area of the silicon single crystal substrate can be Φ10mm~Φ100mm or 10mm×10mm~100mm×100mm; the prepared inorganic-organic hybrid porous SiO 2 The thickness of the film is 2 μm to 6 μm.

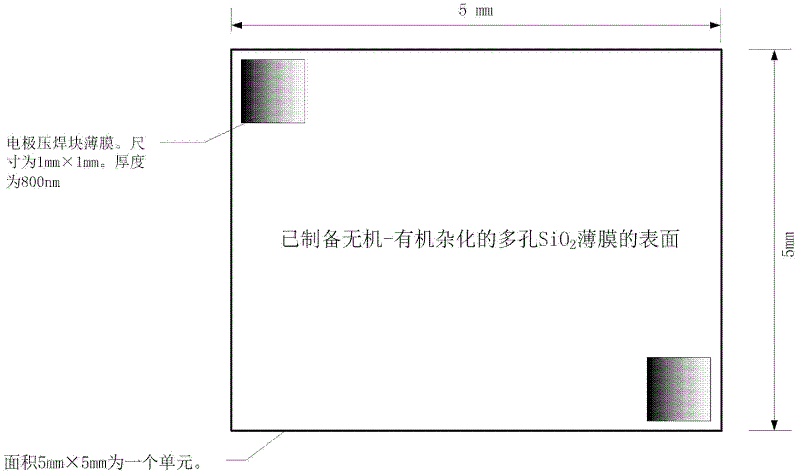

[0026] In this embodiment, an area of 20mm×20mm is taken, and the surface is coated with silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com