Method for evaluating vapor blocking performance

An evaluation method, water vapor technology, applied in the direction of suspension and porous material analysis, permeability/surface area analysis, measuring device, etc., can solve the problems of complicated preparation process, time-consuming, time-consuming and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

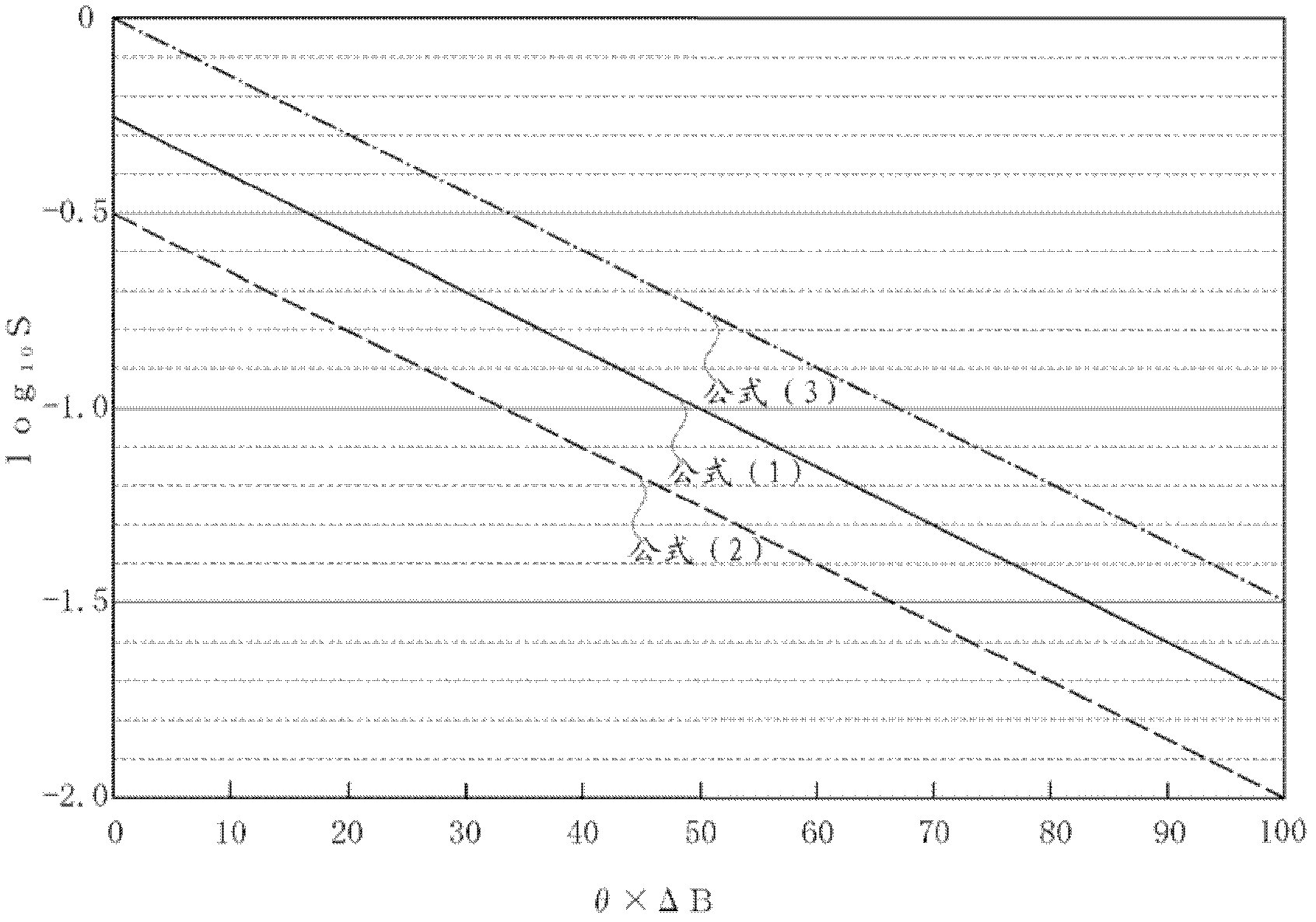

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

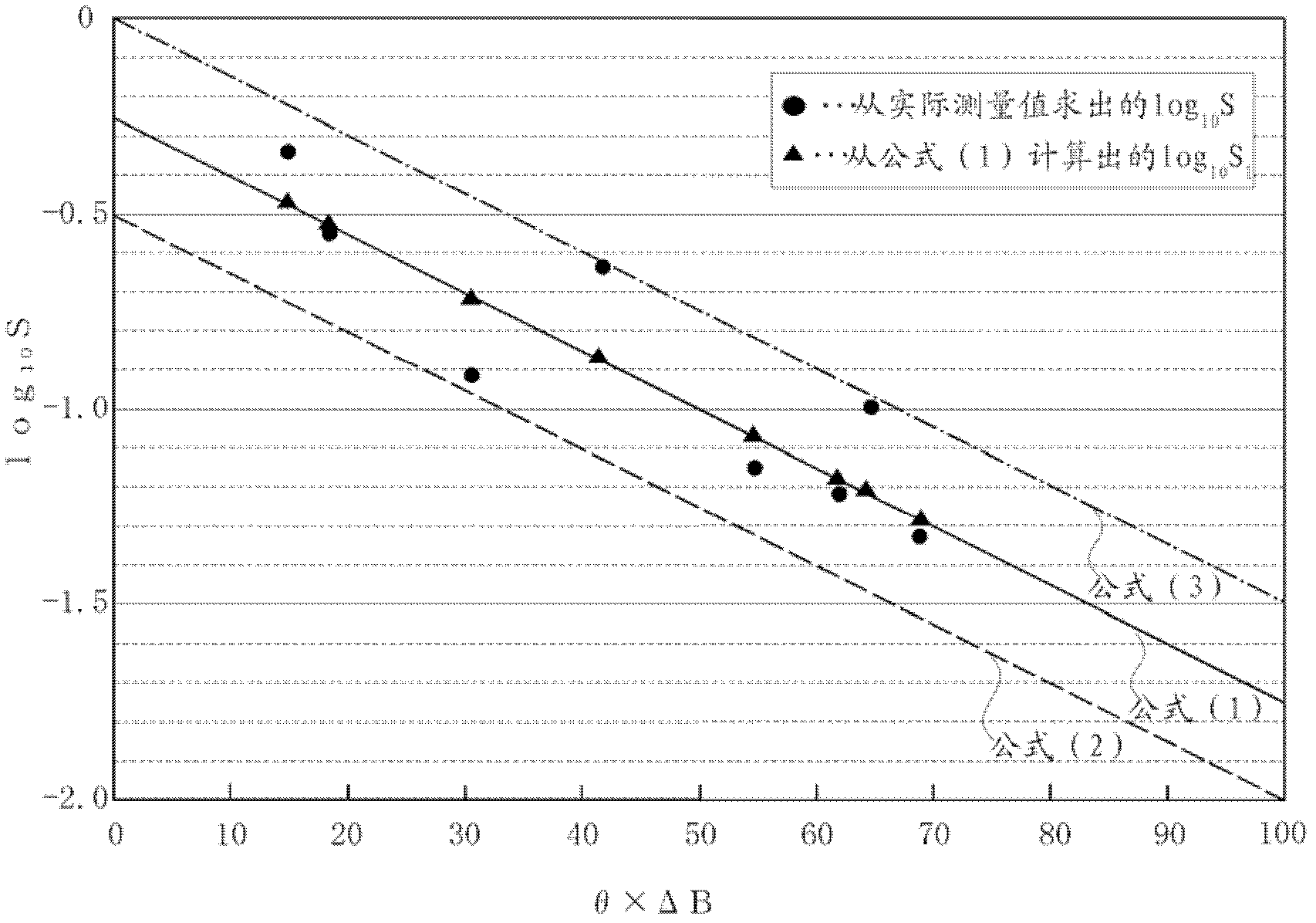

[0053] A test piece in which a water vapor barrier film was formed on a glass substrate was obtained under the conditions shown in Table 1 below. In addition, the film formation of the water vapor barrier film is carried out by reactive plasma vapor deposition, and Examples 1 to 7 use a vapor deposition material composed of the first oxide (X) and a vapor deposition material composed of the second oxide (Y). Co-deposition of two vapor deposition materials was performed, and Example 8 was performed using one vapor deposition material including both the first oxide (X) and the second oxide (Y).

Embodiment 8

[0053] A test piece in which a water vapor barrier film was formed on a glass substrate was obtained under the conditions shown in Table 1 below. In addition, the film formation of the water vapor barrier film is carried out by reactive plasma vapor deposition, and Examples 1 to 7 use a vapor deposition material composed of the first oxide (X) and a vapor deposition material composed of the second oxide (Y). Co-deposition of two vapor deposition materials was performed, and Example 8 was performed using one vapor deposition material including both the first oxide (X) and the second oxide (Y).

[0054] Next, these test pieces were left to stand under conditions of a temperature of 25° C. and a relative humidity of 50% RH for one day, and then the water drop contact angle θ of the water vapor barrier film was obtained. The water droplet contact angle θ is a contact angle based on a droplet method measured 2 seconds after dropping 2 μL of ion-exchanged water onto a film formed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com