Medium-and-low-temperature solar selective absorption thin film and preparation method thereof

A technology that selectively absorbs and solar energy is applied in the field of solar photothermal conversion, which can solve the problems of reducing film performance and achieve low cost, strong practical value, and good process stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

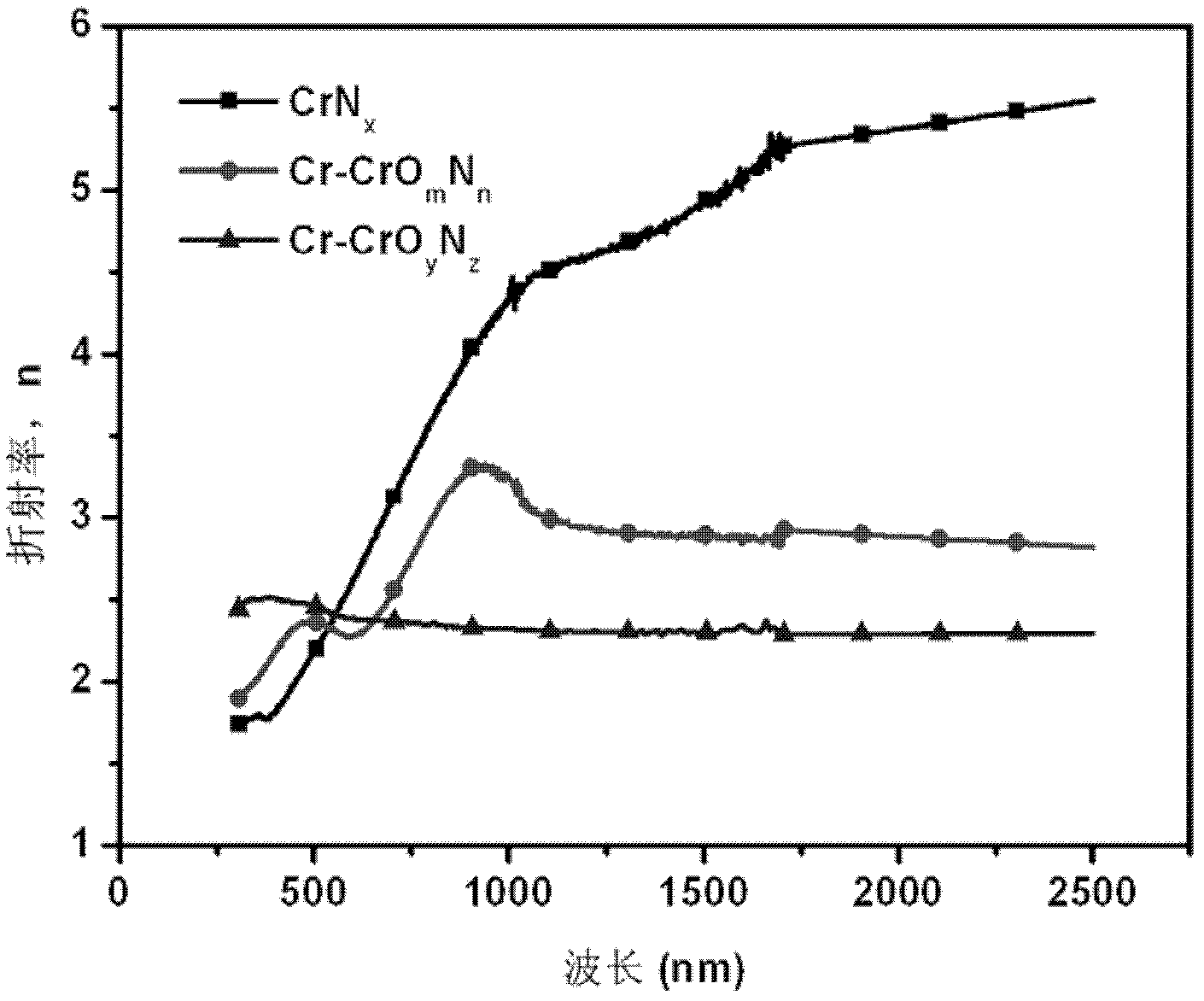

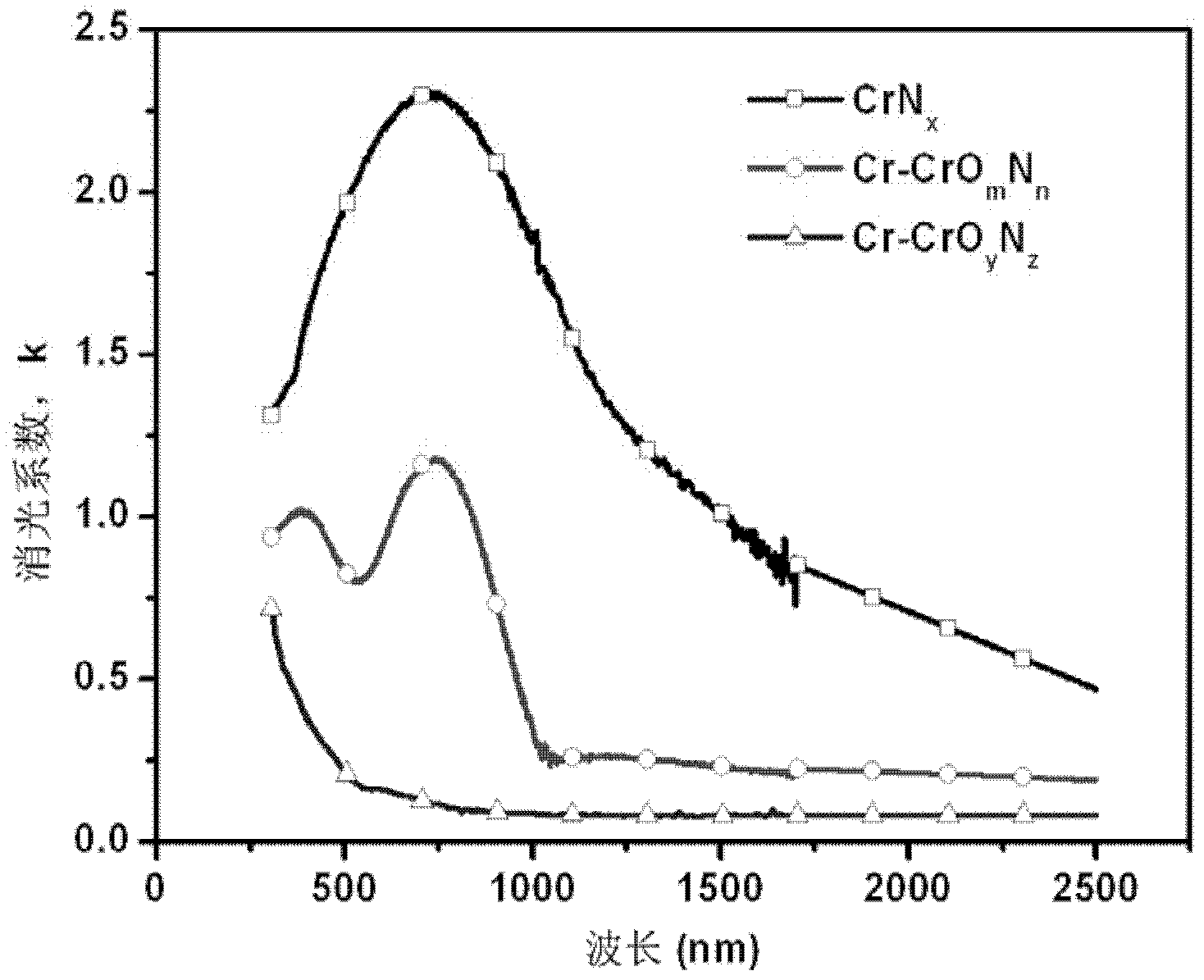

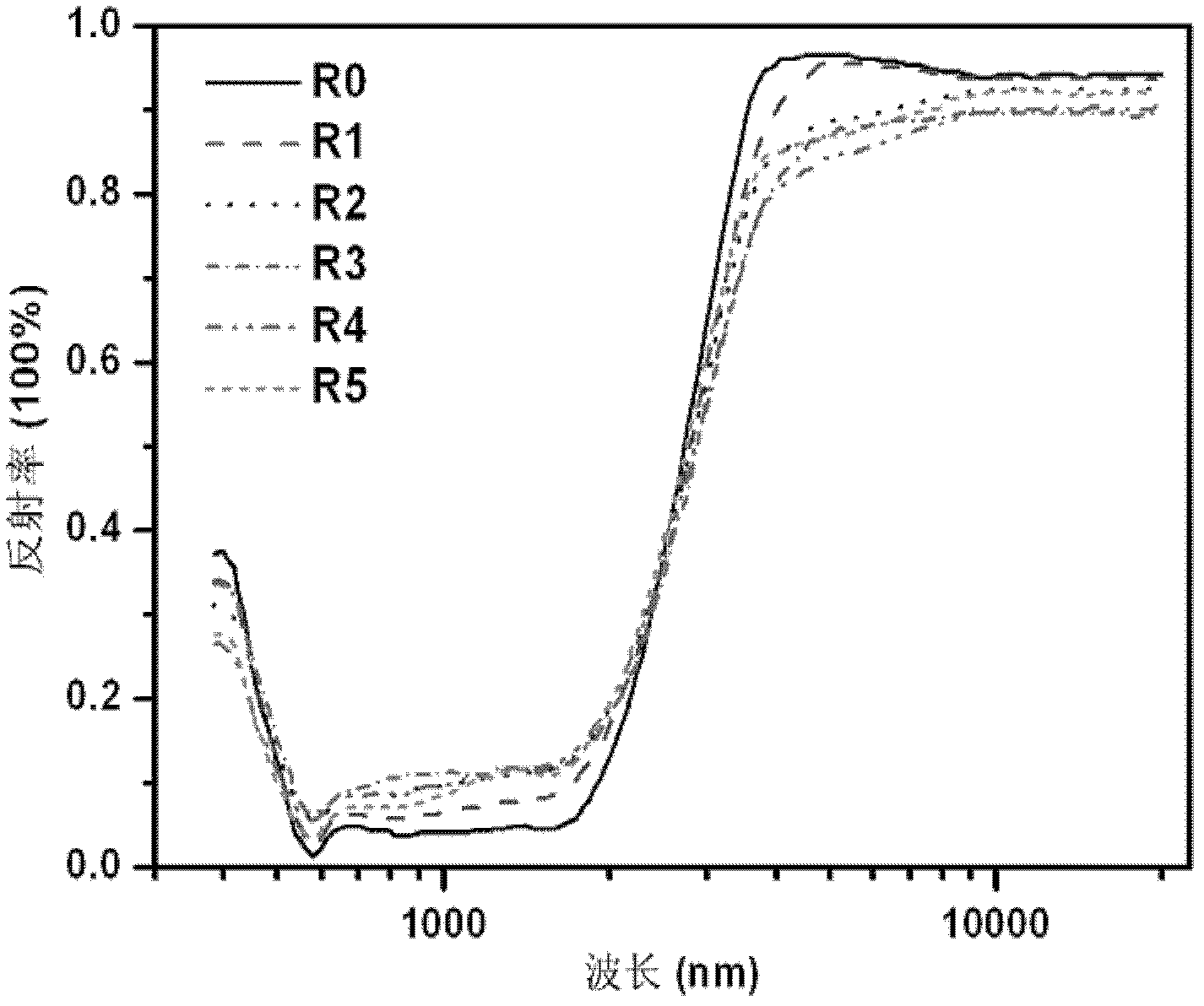

[0041] This example describes the process of preparing a medium-low temperature solar selective absorption film on a pure aluminum substrate, and analyzes its performance.

[0042] Step 1: Pretreatment of the substrate: select pure aluminum foil (thickness 0.4mm) as the substrate of the absorbing coating, clean it with detergent, deionized water, acetone and alcohol for 10 minutes, and dry it with N2 gas. Put it into the vacuum chamber and wait for the vacuum to reach 2×10 -4 After Pa, it was baked at 300°C for 30 minutes, and then Ar plasma treatment was performed on the sample by a reverse sputtering device, wherein the Ar pressure was 0.45 Pa, and the treatment time was 10 minutes to obtain a pretreated substrate.

[0043] Step 2: Preparation of the infrared reflective layer: select the metal Cu target material, pass Ar gas into the vacuum chamber, and prepare the metal infrared reflective layer on the pretreated substrate at room temperature by DC magnetron sputtering meth...

Embodiment 2

[0054] This example describes the process of preparing a medium-low temperature solar selective absorption thin film on a pure aluminum substrate, and analyzes its performance.

[0055] Step 1: Pretreatment of the substrate: select pure aluminum foil (thickness 0.4mm) as the substrate of the absorbing coating, clean it with detergent, deionized water, acetone and alcohol in order for 10 minutes, and pass through N 2 After the air is dried, put it into the vacuum chamber and wait for the vacuum to reach 2×10 -4 After Pa, it was baked at 300°C for 30 minutes, and then Ar plasma treatment was performed on the sample by a reverse sputtering device, wherein the Ar pressure was 0.45 Pa, and the treatment time was 10 minutes to obtain a pretreated substrate.

[0056] Step 2: Preparation of the infrared reflective layer: select the metal Cu target material, pass Ar gas into the vacuum chamber, and prepare the metal infrared reflective layer on the pretreated substrate at room temperat...

Embodiment 3

[0063] This example describes the process of preparing a medium-low temperature solar selective absorption film on a copper substrate, and analyzes its performance.

[0064] Step 1: Select red copper (thickness 0.2mm) as the substrate of the absorbing coating, clean it with detergent, deionized water, acetone and alcohol in sequence for 10 minutes, and pass through N 2 After air drying, put it into a vacuum chamber. To be vacuumed to 2×10 -4 After Pa, it was baked at 300°C for 30 min, and then the sample was treated with Ar plasma by a reverse sputtering device, where the Ar pressure was 0.46 Pa, and the treatment time was 10 min. The copper substrate also serves as an infrared reflective layer.

[0065] Step 2: Preparation of diffusion barrier layer and absorbing layer: use Cr target, adopt reactive magnetron sputtering method, pass Ar gas and N into the vacuum chamber at the same time 2 gas, on the infrared reflective layer to prepare Cr x N diffusion barrier layer, wher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com