Color bending-resistant co-extruded section bar reflecting infrared rays and preparation method thereof

A kind of anti-bending, infrared technology, applied in the field of extrusion processing of plastic products, can solve the problems of affecting sealing and service life, and achieve the effect of increasing service life, reducing the amplitude of thermal deformation, and avoiding the reduction of sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Embodiment 1: A colored co-extruded profile that reflects infrared rays and resists bending: contains 100 parts of acrylic acid-styrene-acrylonitrile copolymer or polymethyl methacrylate in parts by weight; 0 to 110 parts of PVC; 5 parts of stabilizer 1 to 16 parts; 1 to 12 parts of processing aid; 5 to 25 parts of impact modifier; 1 to 70 parts of potassium titanate whisker after treatment with silane coupling agent. Potassium titanate whiskers treated with stabilizers, processing aids, impact modifiers and silane coupling agents are all known technologies.

Embodiment 2

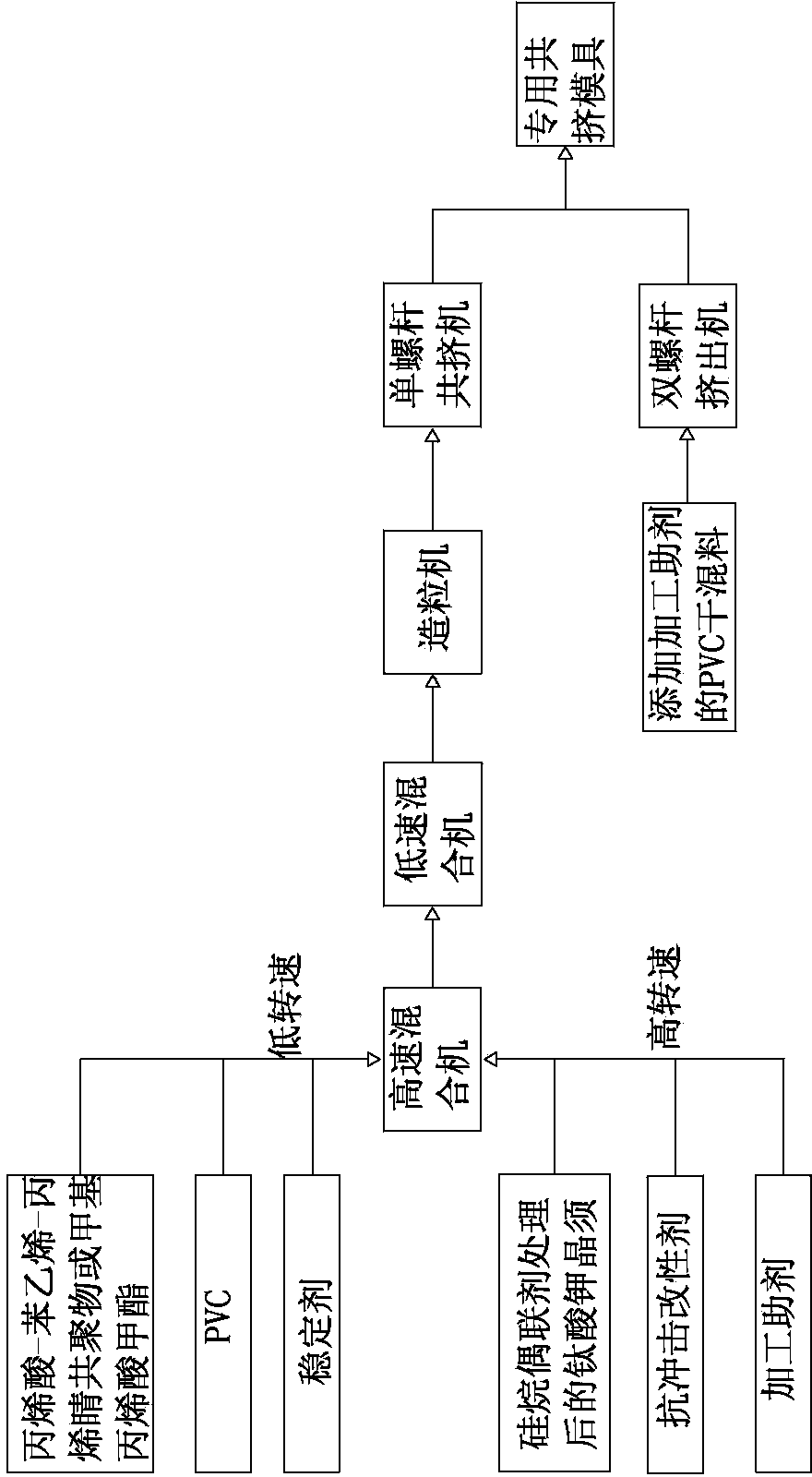

[0011] Embodiment 2: A preparation method of a colored co-extruded profile that reflects infrared rays and is resistant to bending: proceed as follows: Step 1: Mix acrylic acid-styrene-acrylonitrile copolymer or polymethyl acrylic acid at a low speed state of a high-speed mixer Add methyl acrylate, PVC and stabilizer to the high-speed mixer, and then heat the added material at the high speed of the high-speed mixer to make the temperature of the material reach 60°C to 80°C; the second step: in the high-speed mixer Add the potassium titanate whiskers treated with processing aids, impact modifiers and silane coupling agents into the high-speed mixer under the rotating speed state and continue heating until the material temperature in the high-speed mixer reaches 110°C to 130°C. Discharge the materials in the high-speed mixer into the rotating low-speed mixer at the low speed state of the high-speed mixer to cool down, wait until the temperature of the materials in the low-speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com