Acrylic polymer material with high refractive index

A technology for polymers and medical equipment, which is applied to non-active ingredients in medical preparations, drug combinations, pharmaceutical sciences, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

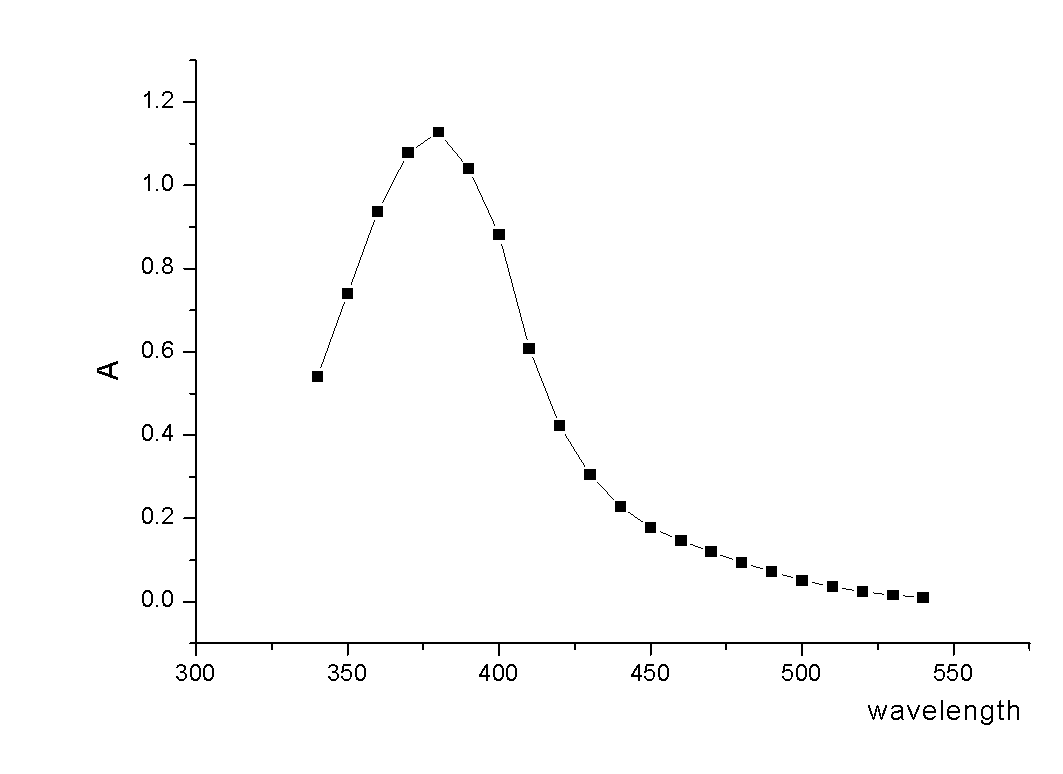

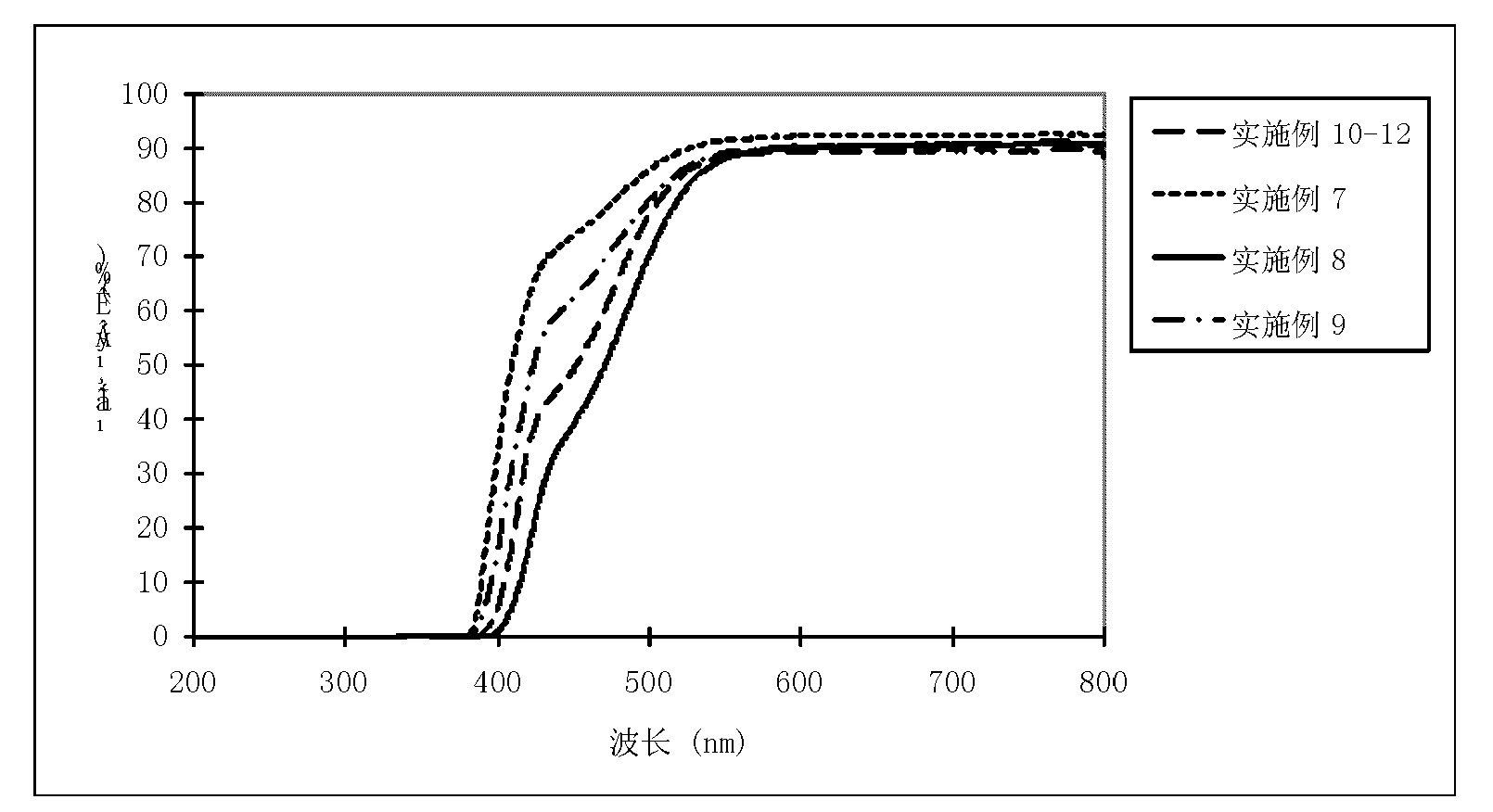

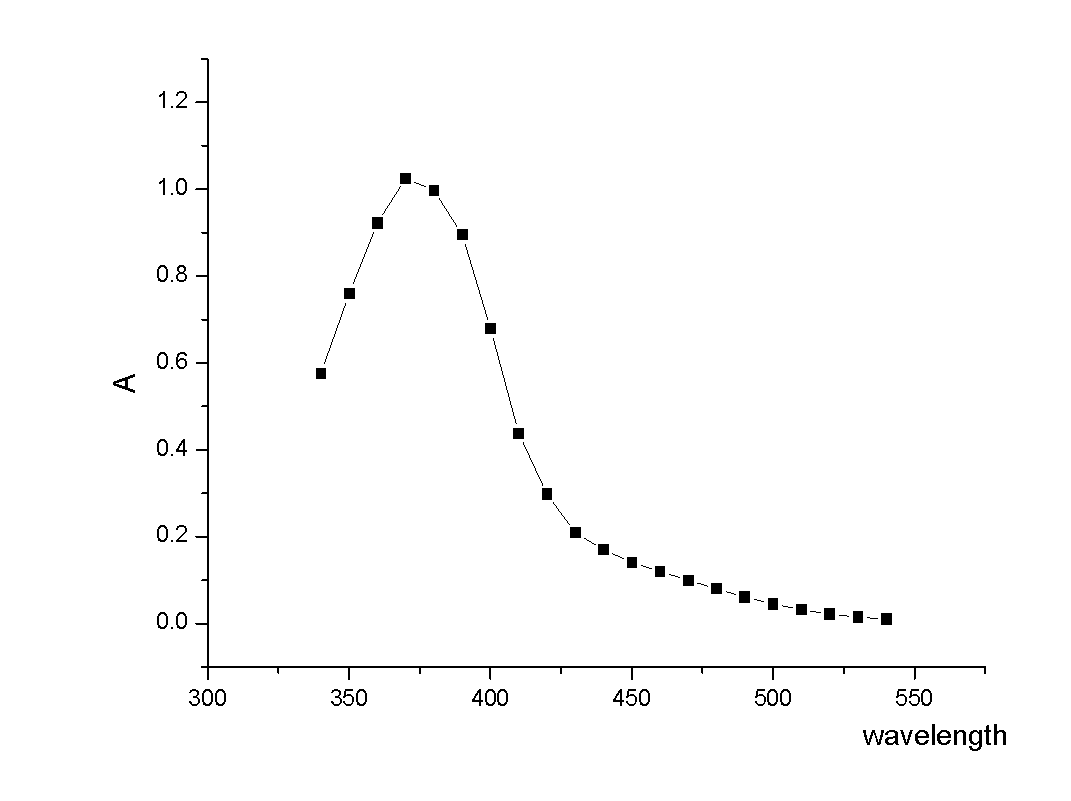

Image

Examples

preparation Embodiment 1

[0133]

[0134] Weigh 12.17g (0.12mol) of 36% hydrochloric acid in a 100ml three-neck flask, add 20ml of water, add 4.14g (0.03mol) of p-nitroaniline, dissolve into a transparent liquid, cool down to 0-5°C, add dropwise 2.07g ( 0.03mol) sodium nitrite solution, keep warm for 1h and set aside; weigh 3.4g (0.03mol) m-cresol in a 1000ml beaker, add 100ml water, add 1.2g (0.03mol) sodium hydroxide to dissolve. Slowly drop the above diazo solution into the beaker to complete the coupling. Filter, wash and dry.

[0135] Weigh 2.7g (0.01mol) of the above dye into a 100ml three-neck flask, add 40ml of water, add 2.6g (0.02mol) of sodium sulfide solution, heat up to 94-95°C after the addition, and keep it warm for about 1h to complete the reaction. Use 36% hydrochloric acid to adjust the ph to partial acidity, and solids precipitate out, filter, wash with water, and dry. The yield is more than 95%, and the HPLC content is more than 95%.

[0136] Weigh 2.39g (0.01mol) of the above ...

preparation Embodiment 2

[0138]

[0139] Weigh 12.17g (0.12mol) of 36% hydrochloric acid in a 100ml three-neck flask, add 20ml of water, add 4.14g (0.03mol) of p-nitroaniline, dissolve into a transparent liquid, cool down to 0-5°C, add dropwise 2.07g ( 0.03mol) sodium nitrite solution, keep warm for 1h and set aside; weigh 3.4g (0.03mol) m-cresol in a 1000ml beaker, add 100ml water, add 1.2g (0.03mol) sodium hydroxide to dissolve. Slowly drop the above diazo solution into the beaker to complete the coupling. Filter, wash and dry.

[0140] Weigh 2.56g (0.01mol) of the above dye into a 100ml three-neck flask, add 40ml of water, and add 2.6g (0.02mol) of sodium sulfide solution. After the addition, raise the temperature to 94-95°C and keep it warm for about 1 hour to complete the reaction. Use 36% hydrochloric acid to adjust the ph to partial acidity, and solids precipitate out, filter, wash with water, and dry. The yield is more than 95%, and the HPLC content is more than 95%.

[0141] Weigh 2.24g ...

preparation Embodiment 3

[0143]

[0144] Weigh 12.17g (0.12mol) of 36% hydrochloric acid in a 100ml three-neck flask, add 20ml of water, add 4.14g (0.03mol) of p-nitroaniline, dissolve into a transparent liquid, cool down to 0-5°C, add dropwise 2.07g ( 0.03mol) sodium nitrite solution, keep warm for 1h and set aside; weigh 3.4g (0.03mol) m-cresol in a 1000ml beaker, add 100ml water, add 1.2g (0.03mol) sodium hydroxide to dissolve. Slowly drop the above diazo solution into the beaker to complete the coupling. Filter, wash and dry.

[0145]Weigh 2.87g (0.01mol) of the above dye into a 100ml three-neck flask, add 40ml of water, add 2.6g (0.02mol) of sodium sulfide solution, after the addition is complete, raise the temperature to 94-95°C, and keep it warm for about 1h to complete the reaction. Use 36% hydrochloric acid to adjust the ph to partial acidity, and solids precipitate out, filter, wash with water, and dry. The yield is more than 95%, and the HPLC content is more than 95%.

[0146] Weigh 2....

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com