Method for preparing high-purity tabular corundum with low energy consumption

A high-purity tabular alumina technology, which is applied in the field of preparing high-purity tabular alumina with low energy consumption, can solve the problems of increased production costs and high energy consumption for firing, and achieve the effects of shortening firing time, improving purity, and good high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

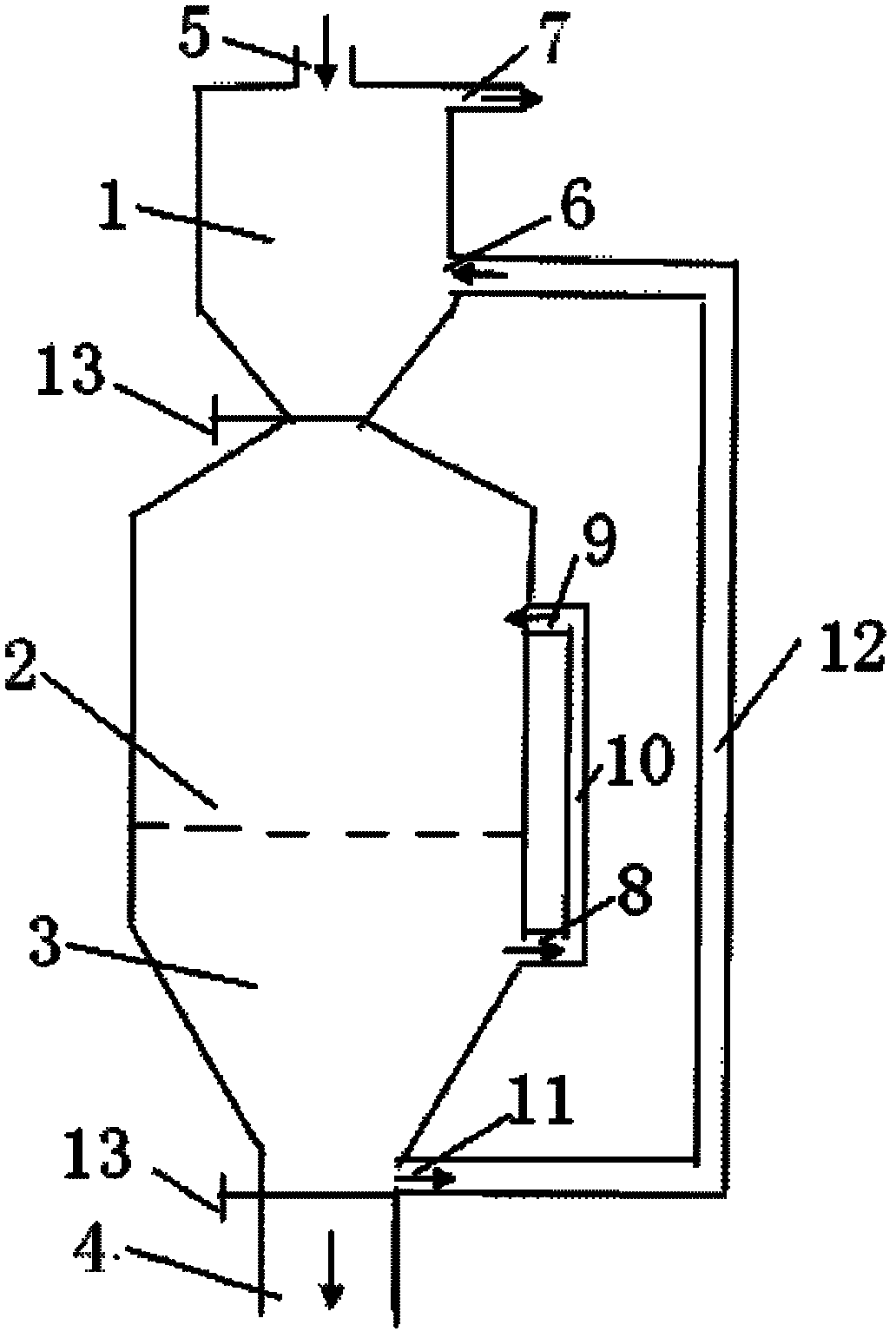

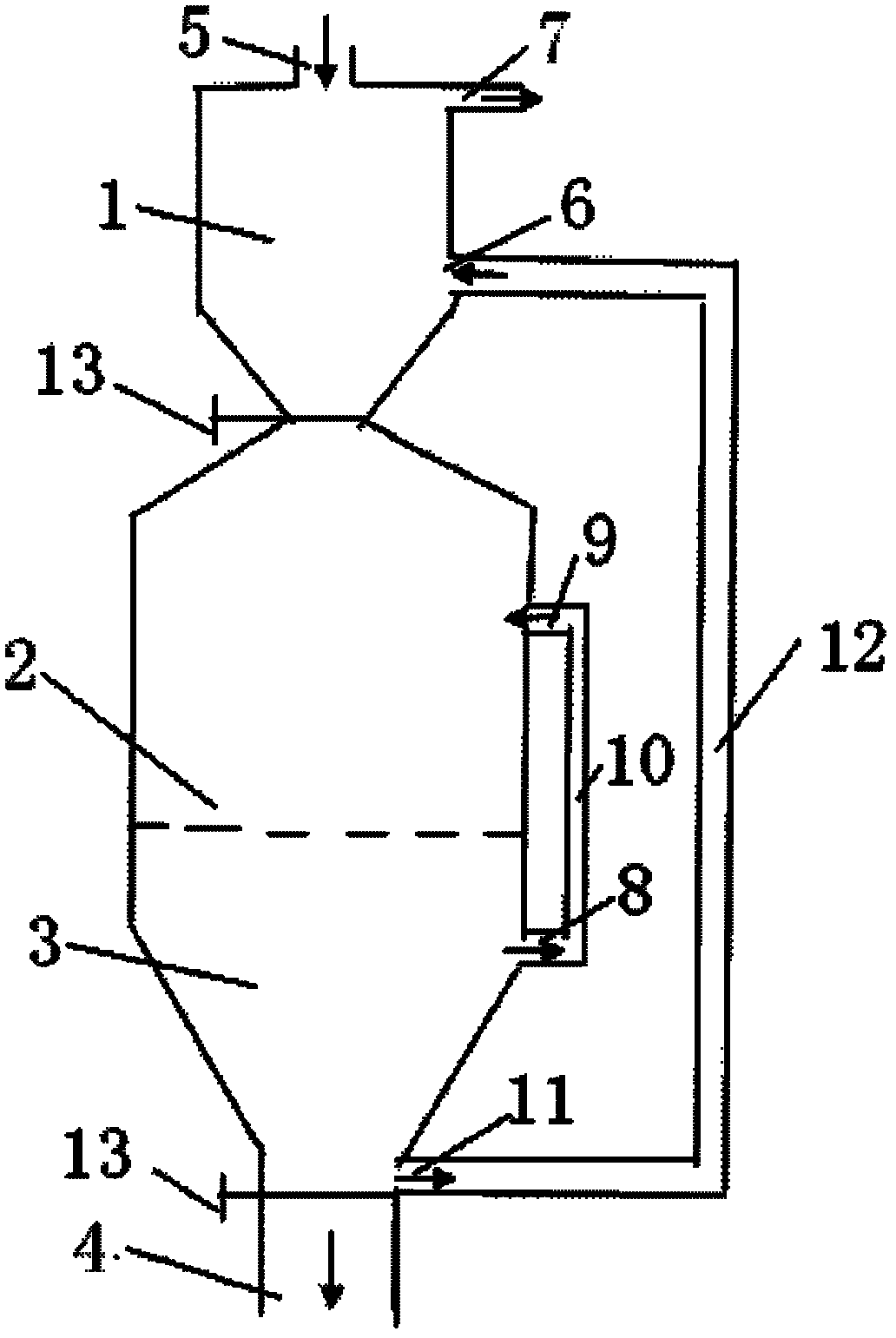

[0027] A high-temperature shaft kiln, its structure diagram is shown in the attached figure 1 , the specific structure is as follows:

[0028] The high-temperature shaft kiln consists of a drying chamber 1, a firing chamber 2, a cooling chamber 3 and a discharge port 4 from top to bottom; Inlet 6, waste gas outlet 7 is arranged above the side wall of the drying chamber; combustion-supporting hot air outlet 8 is arranged above the side wall of the cooling chamber, and combustion-supporting hot air inlet 9 and combustion-supporting hot air outlet 8 are arranged on the side wall of the firing chamber It communicates with the combustion-supporting hot-blast inlet 9 through a combustion-supporting hot-blast pipeline 10; a hot-blast outlet 11 is arranged below the side wall of the cooling chamber, and the hot-blast outlet 11 and the hot-blast inlet 7 below the sidewall of the drying chamber pass through a drying hot-blast pipeline 12 connected.

[0029] The high-temperature hot ai...

Embodiment 2

[0037] The method for preparing high-purity tabular alumina with the high-temperature shaft kiln of Example 1, the specific steps are:

[0038] (1) Mix 1000 kg of calcined industrial alumina powder with a purity of 98.5%, 5 kg of boric acid and 3 kg of aluminum fluoride in a QM-1 ball mill, use sintered plate-shaped corundum balls as grinding bodies, and dry grind to obtain an average Mixtures with a particle size of less than 5 microns.

[0039] (2) Add 5 kg of hydroxypropyl methylcellulose and 80 kg of water to the above mixture, and make green balls with a diameter of 20 mm to 30 mm in a drum type ball forming machine (model Φ2.5*3m).

[0040] (3) Send the green balls to the drying chamber at the top of the high-temperature shaft kiln, and dry the green balls with hot air drawn from the bottom of the cooling chamber of the high-temperature shaft kiln. The temperature of the hot air is 400°C to 650°C, and the drying time is 120 minutes;

[0041] (4) The dried green balls en...

Embodiment 3

[0044] The method for preparing high-purity tabular alumina with the high-temperature shaft kiln of Example 1, the specific steps are:

[0045] (1) Mix 1000 kg of calcined industrial alumina powder with a purity of 98.5%, 5 kg of boric acid and 5 kg of aluminum fluoride in a QM-1 ball mill, use sintered plate-shaped corundum balls as grinding bodies, and dry grind to obtain an average Mixtures with a particle size of less than 5 microns.

[0046] (2) Add 6 kg of hydroxypropyl methylcellulose and 100 kg of water to the above mixture, and make green balls with a diameter of 20 mm to 30 mm in a drum type ball forming machine (model Φ2.5*3m).

[0047] (3) Send the green balls to the drying chamber at the top of the high-temperature shaft kiln, and dry the green balls with hot air drawn from the bottom of the cooling chamber of the high-temperature shaft kiln. The temperature of the hot air is 400°C to 650°C, and the drying time is 100 minutes;

[0048] (4) The dried green balls e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com