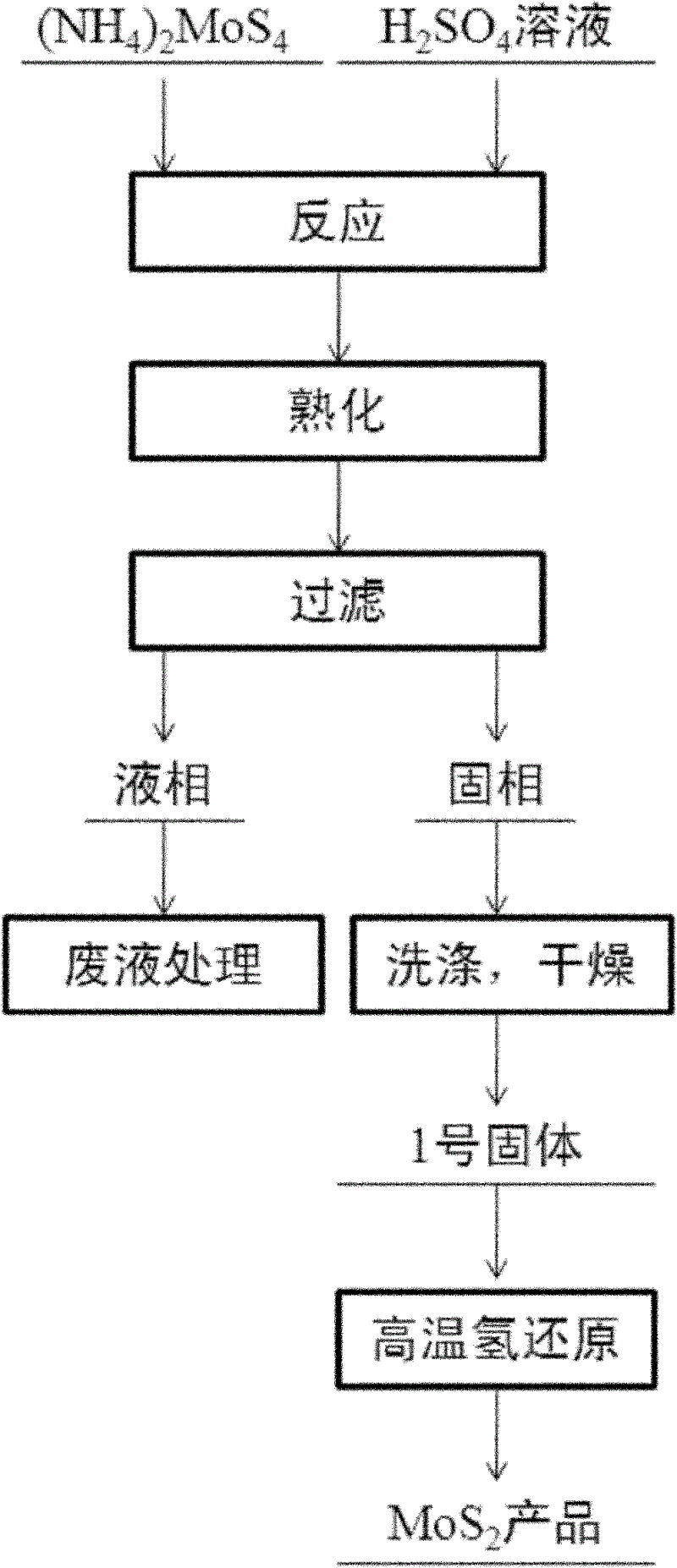

Preparation method of monodisperse spherical MoS2 ultrafine powder

An ultra-fine powder, monodisperse technology, applied in the direction of molybdenum sulfide, nanotechnology, etc., can solve the problems of long production process, large impact on subsequent applications, low recovery rate of molybdenum, etc., to achieve good product quality and high utilization rate of raw materials , Engineering zoom in easily effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

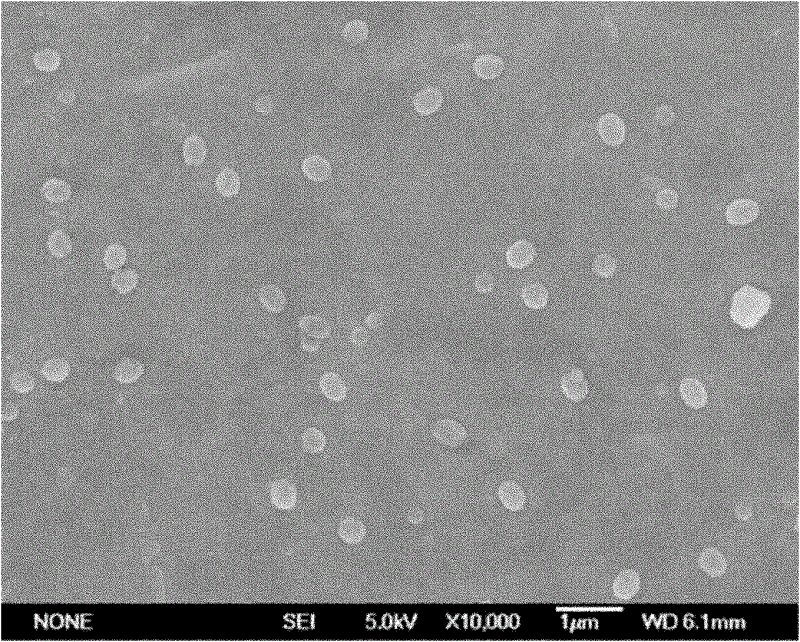

[0030] The ammonium tetrathiomolybdate and sulfuric acid are reacted in a ratio of 1:1, (NH 4 ) 2 MoS 4 The concentration of the solution is 0.01mol / L, the concentration of the sulfuric acid solution is 0.05mol / L, no surfactant is added, the stirring rate is 350rpm, the reaction temperature is 20℃, the feed rate is 0.4L / h with a peristaltic pump, and the solution is taken out after 60min of maturation , Separate and wash the solid 3 times, place it in a constant temperature drying oven at 100°C for 2 hours to obtain MoS 3 Of monodisperse particles, figure 2 Monodisperse spherical MoS 3 Scanning electron microscope (SEM) image of. Weigh a certain amount of MoS 3 Place the monodisperse particles in a porcelain boat, put it into the tubular resistance furnace, close the tubular furnace, and inject nitrogen gas at a rate of 0.8L / min for 30 minutes. After replacing the remaining air in the furnace, reduce the nitrogen flow rate to 0.4L / After the furnace body is heated to 800°C, hyd...

Embodiment 2

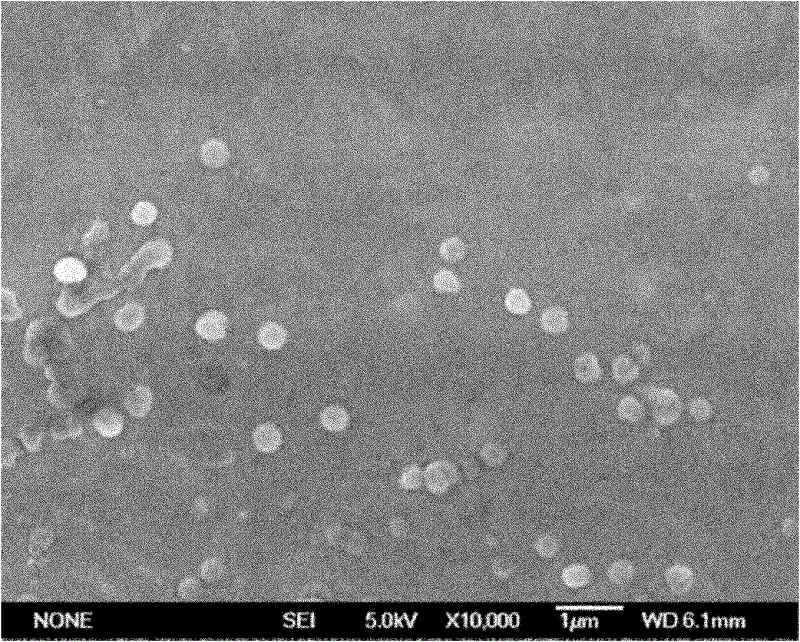

[0032] The ammonium tetrathiomolybdate and sulfuric acid are reacted in a ratio of 1:1, (NH 4 ) 2 MoS 4 The concentration of the solution is 0.05mol / L, the concentration of the sulfuric acid solution is 10mol / L, the sodium dodecylbenzene sulfonate (DBS) is used as the surfactant, and the amount of surfactant added is the same as the amount of ammonium tetrathiomolybdate The ratio is 0.02:1, the stirring rate is 350rpm, the reaction temperature is 60℃, the feed rate is 0.4L / h with a peristaltic pump, the solution is taken out after 30 minutes of maturation, the solid is separated and washed 3 times, and placed in a constant temperature drying oven at 100℃ Dry for 2h to get MoS 3 Monodisperse particles, weigh a certain amount of MoS 3 Place the monodisperse particles in a porcelain boat, put it into the tubular resistance furnace, close the tubular furnace, and inject nitrogen gas at a rate of 0.8L / min for 30 minutes. After replacing the remaining air in the furnace, reduce the nit...

Embodiment 3

[0034] The ammonium tetrathiomolybdate and nitric acid are reacted at a ratio of 1:0.8, (NH 4 ) 2 MoS 4 The concentration of the solution is 0.01 mol / L, the concentration of the nitric acid solution is 0.05 mol / L, and the cetyl trimethyl ammonium chloride (CTAC) is used as the surfactant. The amount of surfactant added is the same as that of ammonium tetrathiomolybdate. The ratio of the amount of substances is 0.05:1, the stirring rate is 350rpm, the reaction temperature is 0°C, the feed rate of the peristaltic pump is 0.4L / h, the solution is taken out after 5 minutes of maturation, the solid is separated and washed 3 times, and placed in a constant temperature drying box Dry at 100℃ for 2h to get MoS 3 Monodisperse particles, weigh a certain amount of MoS 3 The monodisperse particles, the solids are placed in a porcelain boat, put into the tube-type resistance furnace, the tube-type furnace is sealed, and nitrogen is introduced at a rate of 0.8L / min for 30 minutes. After the res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com