Method for preparing high-performance titanium and silicon molecular sieve

A titanium-silicon molecular sieve, high-performance technology, applied in molecular sieve catalysts, chemical instruments and methods, crystalline aluminosilicate zeolites, etc., can solve the problems of poor product catalytic performance and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

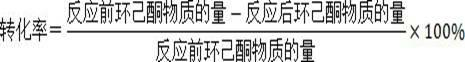

Method used

Image

Examples

Embodiment 1

[0022] Weigh 15g of tetrapropylammonium bromide (TPABr content> 99 wt %), dissolved in 25g water, added 2.4g hydrogen peroxide solution (H 2 O 2 The content is 27wt%), 4g tetrabutyl titanate (TBOT, TiO 2 Content> 23 wt %), using concentrated ammonia (NH 3 The content is 25wt%) adjust the pH to 11, stir until it is clear, and then add 36g silica sol (SiO 2 The content is 31.4wt%), add water to form a molar ratio of 1 SiO 2 : 0.06 TiO 2 : 0.30 TPA + : 0.24 H 2 O 2 : 25H 2 The crystallization mother liquor of O was mixed well and transferred to a stainless steel crystallization kettle lined with polytetrafluoroethylene. It was dynamically crystallized at 170°C for 48 hours. The product was filtered, washed, and dried at 120°C for 6 hours, and then at 550°C. It is calcined for 4 hours to remove the template to obtain the original powder C of the titanium silicate molecular sieve.

Embodiment 2

[0024] Weigh 5g of tetrapropylammonium bromide (TPABr content> 99 wt %), dissolved in 15g water, added 2.4g hydrogen peroxide solution (H 2 O 2 The content is 27wt%), 4g tetrabutyl titanate (TBOT, TiO 2 Content> 23 wt %), using concentrated ammonia (NH 3 The content is 25wt%) adjust the pH to 12, stir until clear, and then add 36g silica sol (SiO 2 The content is 31.4wt%), add water to form a molar ratio of 1 SiO 2 : 0.06 TiO 2 : 0.10 TPA + : 0.24 H 2 O 2 : 25H 2 The crystallization mother liquor of O was mixed well and transferred to a stainless steel crystallization kettle lined with polytetrafluoroethylene. It was dynamically crystallized at 170°C for 48 hours. The product was filtered, washed, and dried at 120°C for 6 hours, and then at 550°C. It is calcined for 4 hours to remove the template agent to obtain the original powder D of titanium silicate molecular sieve.

Embodiment 3

[0026] Weigh 5g of tetrapropylammonium bromide (TPABr content> 99 wt %) and 1.4g ammonium fluoride (NH 4 F content> 99wt%), dissolved in 15g water, added 2.4g hydrogen peroxide solution (H 2 O 2 The content is 27wt%), 4g tetrabutyl titanate (TBOT, TiO 2 Content> 23 wt %), using concentrated ammonia (NH 3 The content is 25wt%) adjust the pH to 12, stir until clear, and then add 36g silica sol (SiO 2 The content is 31.4wt%), add water to form a molar ratio of 1 SiO 2 : 0.06 TiO 2 : 0.10 TPA + : 0.20 F - : 0.24 H 2 O 2 : 25H 2 The crystallization mother liquor of O was mixed well and transferred to a stainless steel crystallization kettle lined with polytetrafluoroethylene. It was dynamically crystallized at 170°C for 48 hours. The product was filtered, washed, and dried at 120°C for 6 hours, and then at 550°C. It is calcined for 4 hours to remove the template agent to obtain the original titanium silicate powder E.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com