Method for producing bright oxygen-free copper rod

An oxygen-free copper rod and bright technology, which is applied in the field of copper rod manufacturing, can solve the problems of high oxygen content and low oxygen content in copper rods, achieve low oxygen content, reduce the impact, and realize the effect of continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

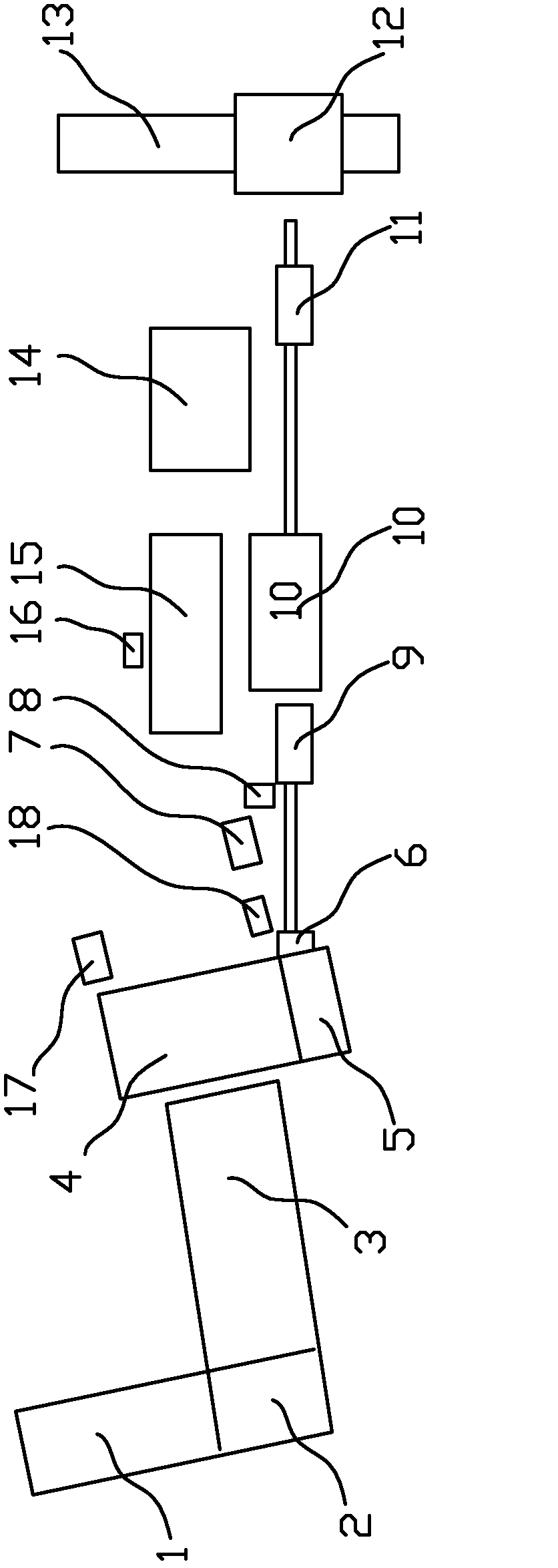

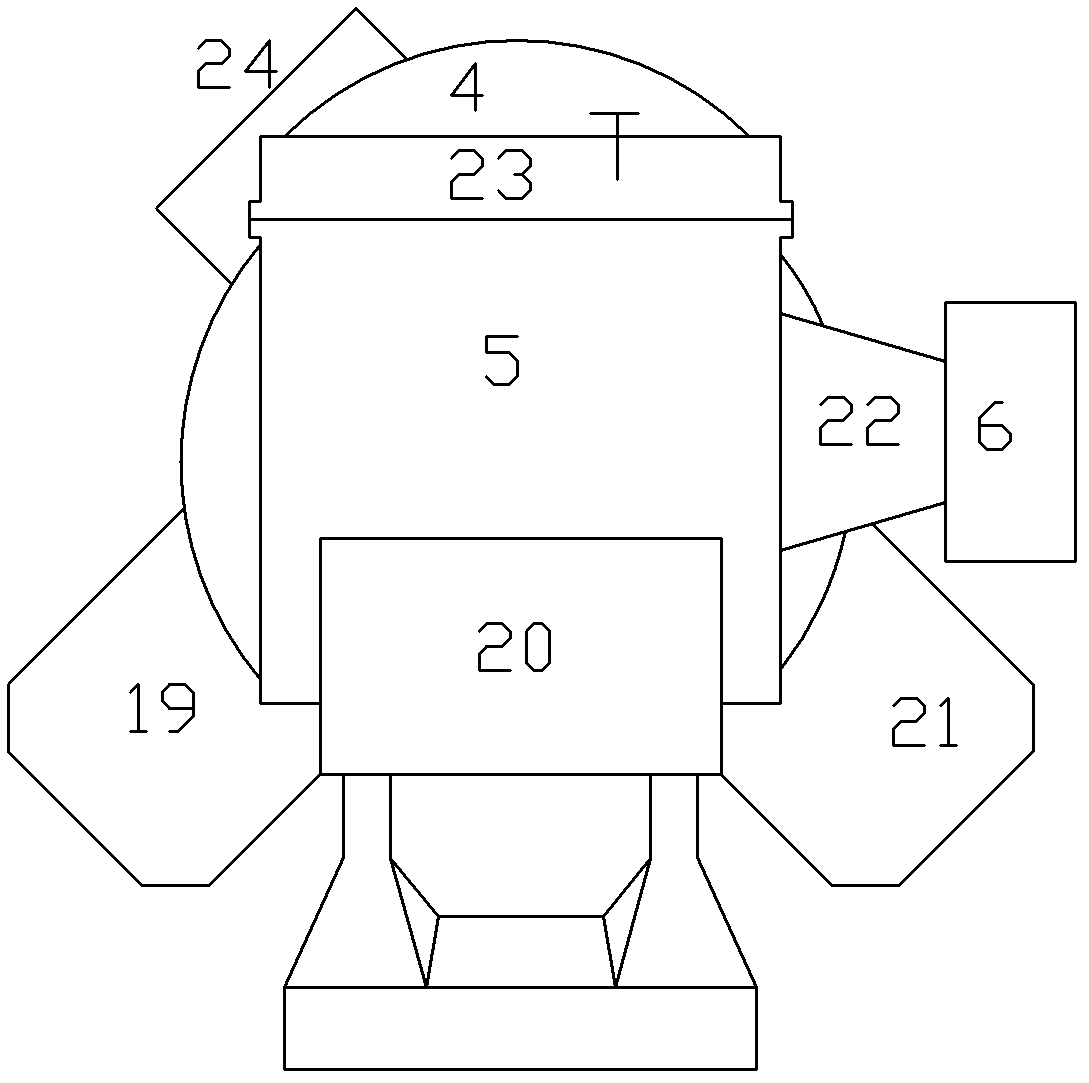

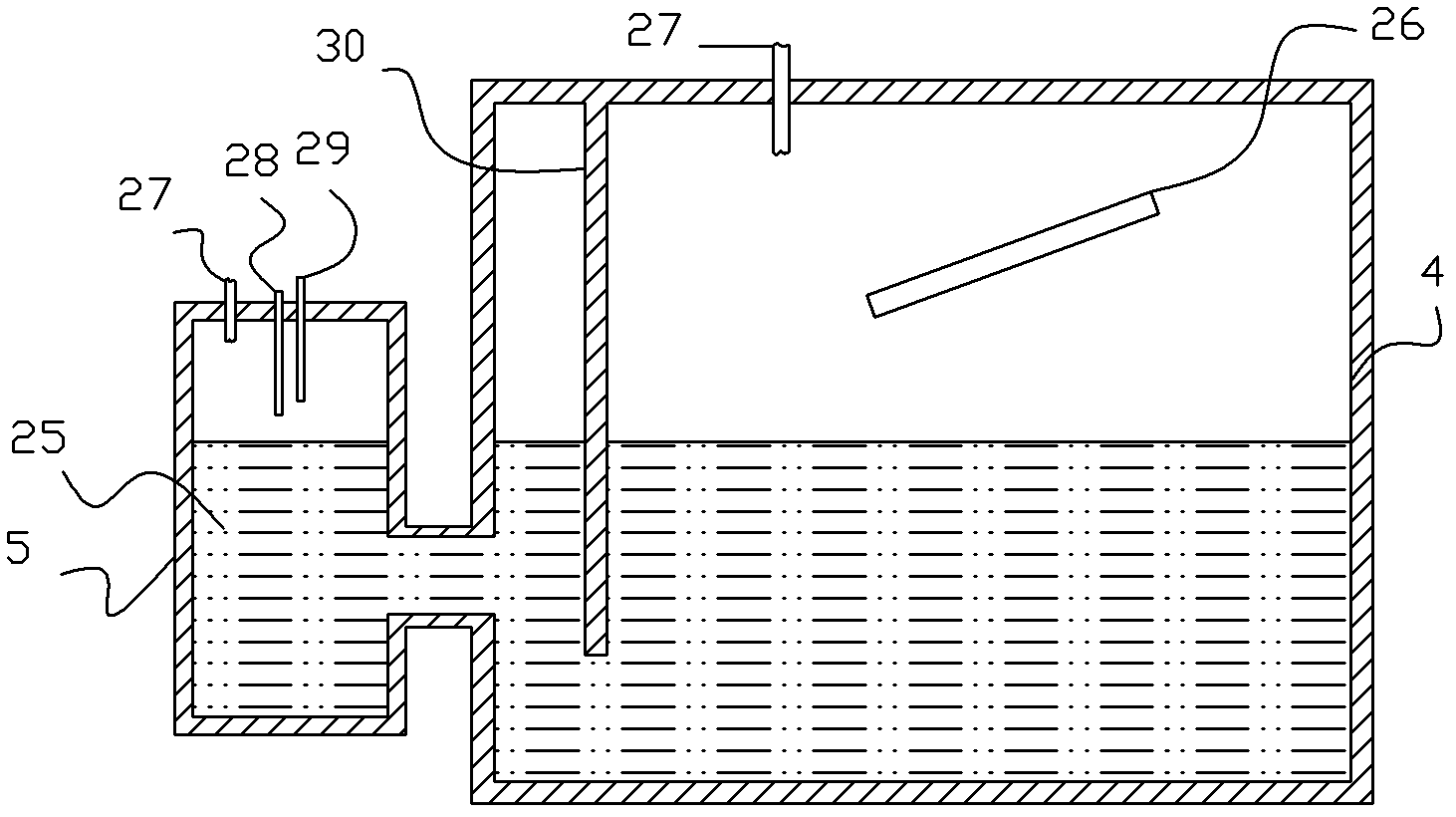

[0080]Bright oxygen-free copper rods were fabricated using the equipment shown in Figures 1 to 4 above. The specific method is to put the electrolytic copper plates heated by the drying furnace into the melting furnace in batches, and dissolve them at a temperature of 1160 degrees. The molten copper flows into the holding furnace through the flow channel to keep warm, and keeps warm at a temperature of 1160°C.

[0081] A thinner copper rod busbar is passed through the coating chamber connected with the holding furnace, and copper liquid is attached to the surface of the copper rod to form a thicker copper casting rod. In addition, before the busbar passes through the coating chamber, it is stripped to remove the oxygen-rich oxide layer on the busbar surface.

[0082] Afterwards, the copper rods are sequentially cooled, hot-rolled, and re-cooled. At this time, the temperature of the copper rod covered with copper liquid before entering the hot rolling process after cooling is...

Embodiment 5~7

[0088] When manufacturing bright oxygen-free copper rods, other conditions are the same as in Example 1, except that the processes of attaching molten copper, cooling, hot rolling, recooling, and coiling are repeated as shown in Table 2.

[0089] In addition, in Table 1 to Table 2, for "whether blocking occurred during the annealing process during loop formation", ○ represents the pass state where no blocking occurred; × represents the unacceptable state that blocking occurred.

[0090] For the "welding state", respectively use ◎ to indicate that when the terminal is welded to a bright oxygen-free copper rod, the solder joint has no air bubbles at all; Insufficient welding with air bubbles.

[0091] In addition, in the "comprehensive results", after comprehensively examining "whether sticking occurs during the annealing process during loop formation" and "welding state", ◎ indicates a very ideal result; ○ indicates an ideal result; × indicates bad result.

[0092] Accordingl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com