Mold manufacture method and mold formed by said method

A technology of metal mold and manufacturing method, which is applied in the photoplate making process of patterned surface, semiconductor/solid-state device manufacturing, transportation and packaging, etc., and can solve the problems of filling holes that cannot be plated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

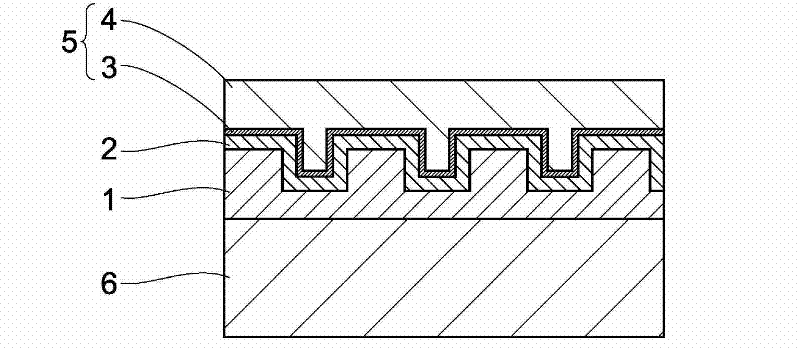

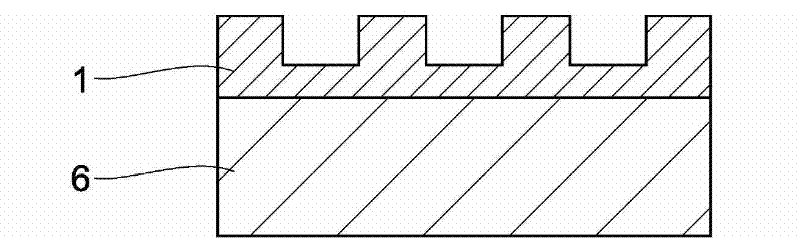

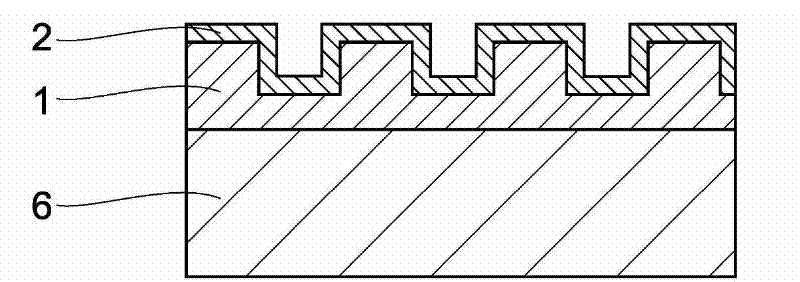

Method used

Image

Examples

Embodiment 1)

[0069] First, a nanoscale pattern is formed on an Si oxide film which is an inorganic thin film formed on a Si substrate. Si substrates use 1-inch wafers. In addition, the specification of the formed pattern was 200 nm in diameter.

[0070] Then, a self-assembled film is formed by liquid phase growth on the pattern. In this example, a toluene solution containing 1 wt.% of a silane coupling agent heated to 60° C. was used as the first solution, and a self-assembled film was formed by dipping in the solution for 10 minutes. As the silane coupling agent, 3-[2-(2-aminoethylamino)ethylamino]propyl-trimethoxysilane (TAS) was used.

[0071] Next, a metal ion layer and a thin film plating layer are sequentially formed as a conductive layer. The metal ion layer was formed by immersing the Si substrate on which the self-assembled film had been formed in a solution containing Pd as the second solution for 1 minute. The solvent uses dilute hydrochloric acid. In addition, the concentr...

Embodiment 2)

[0078] Next, the adhesion between the inorganic thin film and the conductive layer was confirmed. Self-assembled films were formed on Si substrates using 3-[2-(2-aminoethylamino)ethylamino]propyl-trimethoxysilane (TAS) as a silane coupling agent. A metal ion layer of Pd is formed on this self-assembled film. Further, an electroless sample is formed on the metal ion layer. As a comparative example, a Si substrate given a Sn-Pd treatment was formed.

[0079] Adhesion was measured using the Figure 9 The assay device 10 is shown. The measurement device 10 includes an electronic digital scale 11 , a displacement meter 12 , a piezoelectric transmission device 13 , a microscope 14 and an electronic computer 15 .

[0080] The electronic digital scale 11 is provided with a sample pan 16 . The sample disk 16 is configured to hold the sample S in a state inclined at a predetermined angle. Also, its given angle is 30 degrees in this embodiment.

[0081] The piezoelectric actuator ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com