Low divergence angle full Bragg reflector waveguide semiconductor laser array

A Bragg reflection and laser array technology, applied in the structure of optical waveguide semiconductors, etc., can solve the problems of poor beam quality, complex process, large divergence angle, etc., to reduce the longitudinal and lateral divergence angles, mature preparation process, and good repeatability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

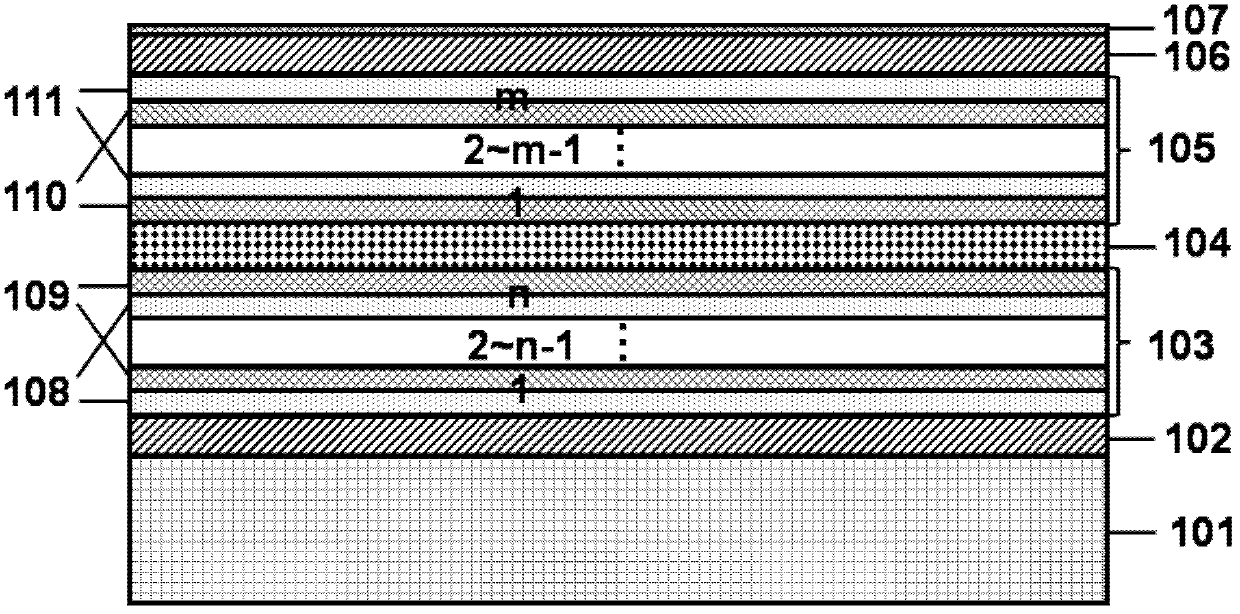

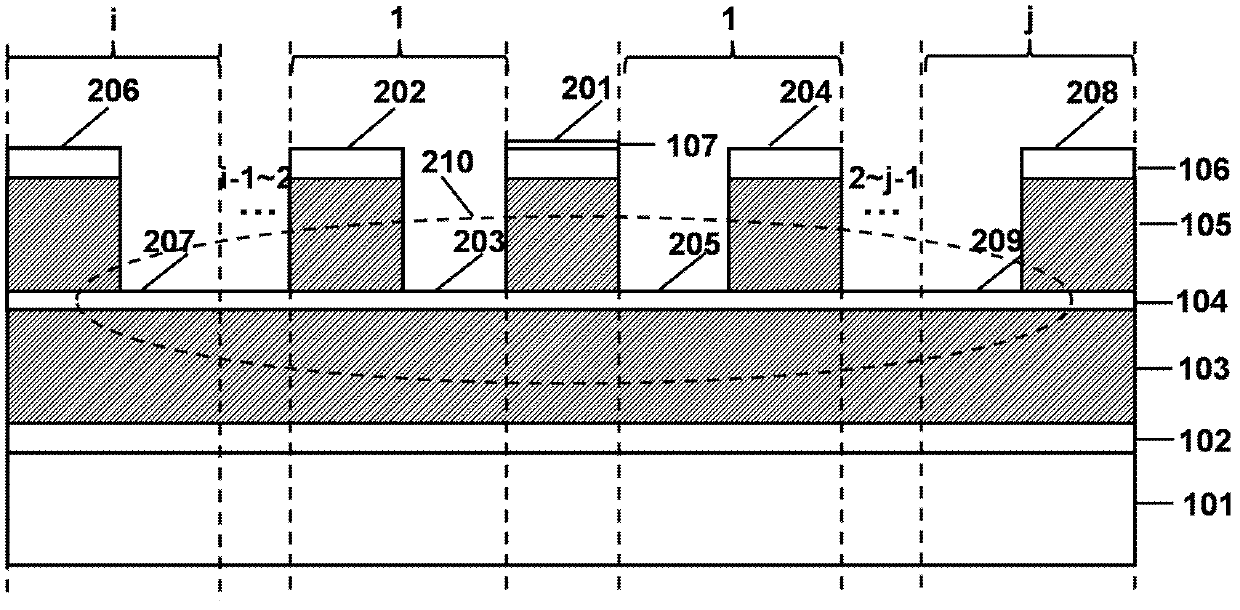

[0013] Such as figure 1 As shown, the longitudinal structure of the low divergence angle full Bragg reflective waveguide semiconductor laser array of the present invention is as follows from bottom to top: N-type substrate 101, N-type confinement layer 102, N-type Bragg reflective waveguide 103, active region 104, P-type Bragg reflection waveguide 105 , P-type confinement layer 106 , and P-type capping layer 107 . Among them, the N-type Bragg reflective waveguide 103 is composed of n (n≥1) pairs of high and low refractive index materials periodically arranged, and each period includes an N-type high-refractive-index layer 108 and an N-type low-refractive-index layer 109; a P-type Bragg The reflective waveguide 105 is composed of m (m≥1) pairs of high and low refractive index materials periodically arranged, and each period includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com