Resistor body and preparation method thereof, and spark plug and preparation method thereof

A technology of resistors and spark plugs, which is applied in the manufacture of spark plugs, spark plugs, resistors, etc., can solve the problems of high equipment requirements, long production cycle of spark plugs, and easy falling off of silver paste, so as to improve mechanical strength, good mechanical and electrical properties, and improve The effect of thermal shock stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

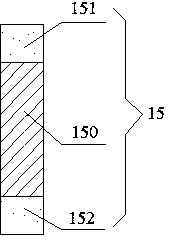

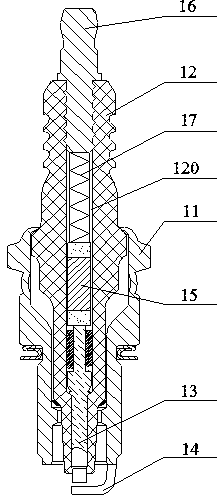

[0038] The present invention also provides a preparation method for the resistor body 15, which includes the following steps: firstly put conductive powder into the pressing mold for pre-press molding; then put resistance powder for pre-press molding; Pressing and maintaining the pressure to obtain a cylindrical blank; finally, sintering the blank in an oxygen-free atmosphere to obtain the resistor 15 .

[0039] The preparation method of the resistor 15 provided by the present invention is formed by pressing the resistor powder and the conductive layer and then sintering, and can be directly assembled into the through hole of the porcelain insulator 12 to prepare the spark plug provided by the present invention, without subsequently combining the resistor with the conductive layer. The porcelain insulator 12, the central electrode 13, and the terminal screw 16 are sintered together, so the requirements for the insulator 12, the central electrode 13, and the terminal screw 16 ar...

Embodiment 1

[0058] (1) Weigh 41 parts by weight of 90 mesh corundum, 22.5 parts by weight of 250 mesh zirconia, 120 mesh lithium calcium barium borosilicate glass (49wt% SiO 2 , 25.6wt%B 2 o 3 , 7wt%Li 2 O, 16wt% BaO, 2.4wt% CaO) 29.2 parts by weight, carbon black N220 3.4 parts by weight, add it to the ball mill and mix for 1h, then move the mixture to the mixer, add zirconium sol (oxychloride Add 12 parts by weight of hydrogen peroxide to calcium, stir for 30 minutes, then bake in an infrared drying oven at 90°C for 8 hours, pass through a 30-mesh and 100-mesh double-layer sieve to obtain resistance powder.

[0059] (2) Weigh 51 parts by weight of 200 mesh copper powder, 7 parts by weight of 200 mesh nickel powder, lithium calcium barium borosilicate glass (49wt% SiO 2 , 25.6wt%B 2 o 3 , 7wt%Li 2 (0, 16wt%BaO, 2.4wt%CaO) 42 parts by weight, add it into the ball mill and mix for 30min, then move the mixture to the mixer, add 10 parts by weight of PVA aqueous solution with a concent...

Embodiment 2

[0070] (1) Weigh 48.5 parts by weight of 100 mesh corundum, 24 parts by weight of 250 mesh zirconia, 100 mesh lithium calcium barium borosilicate glass (46.7wt% SiO 2 , 22wt%B 2 o 3 , 9.2wt%Li 2 O, 18.7wt%BaO, 1.9wt%CaO, 1.5wt%Al 2 o 3 ) 25.6 parts by weight, carbon black N220 1.9 parts by weight, add them to the ball mill and mix for 1 hour, then move the mixture to the mixer, add zirconium sol (made by adding hydrogen peroxide to calcium oxychloride and hydrolyze) 16.5 parts by weight under stirring portion, stirred for 30 minutes, then baked in an infrared drying oven at 90°C for 8 hours, and passed through a 30-mesh and 100-mesh double-layer sieve to obtain resistance powder.

[0071] (2) Weigh 48.5 parts by weight of 200 mesh copper powder, 6.5 parts by weight of 200 mesh nickel powder, lithium calcium barium borosilicate glass (46.7wt% SiO 2 , 22wt%B 2 o 3 , 9.2wt%Li 2 O, 18.7wt%BaO, 1.9wt%CaO, 1.5wt%Al 2 o 3 ) 45 parts by weight, put it into the ball mill and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com