Ladle permanent lining pouring material capable of rapid roasting

A castable and permanent layer technology is applied in the field of unshaped refractory materials, which can solve the problems of easy dropping of bricks when dismantling the working layer of the ladle, difficulty in turnover of the ladle, and low service life, and achieve long service life, high strength and refractoriness. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

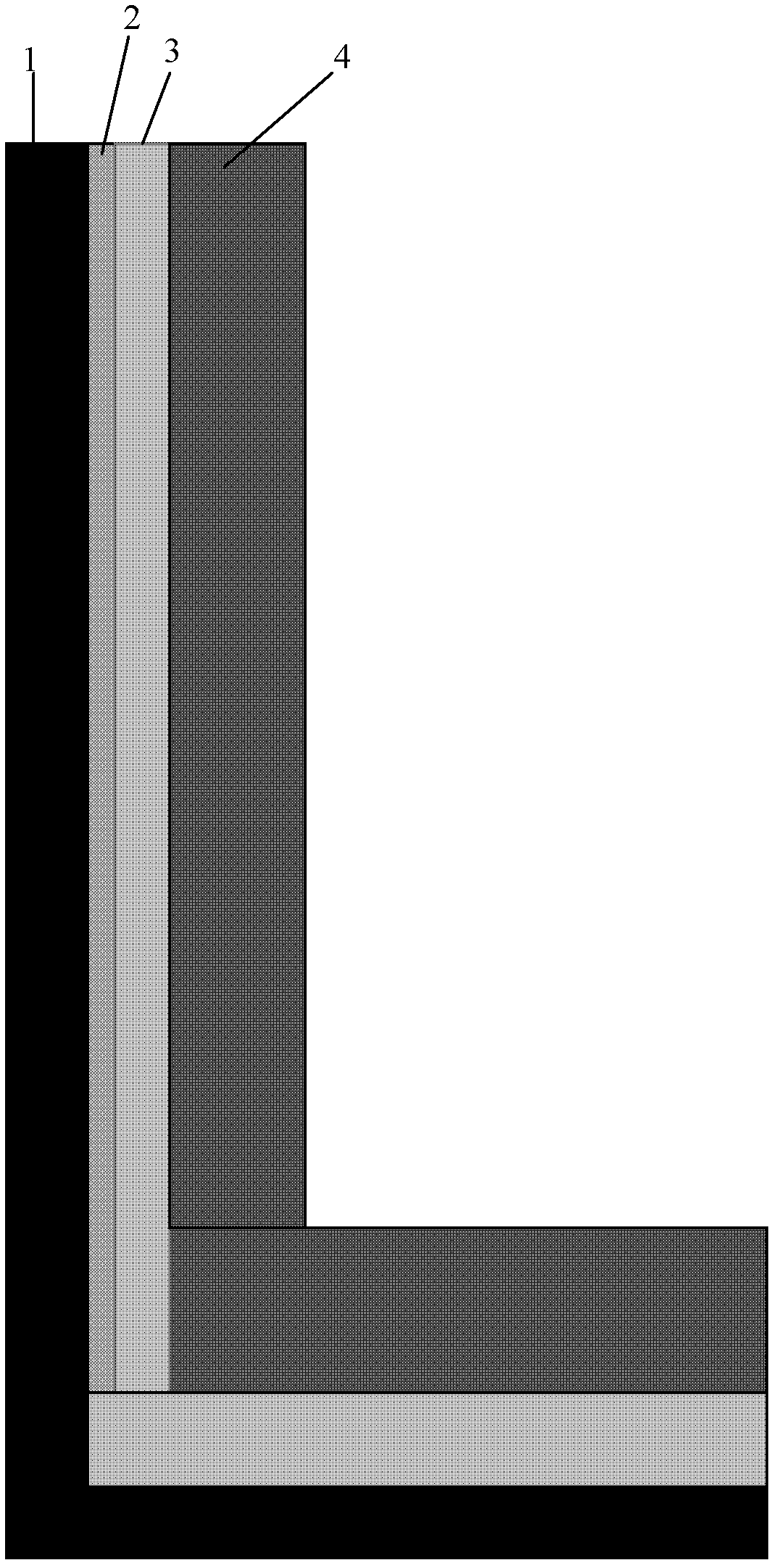

Image

Examples

Embodiment 1-6

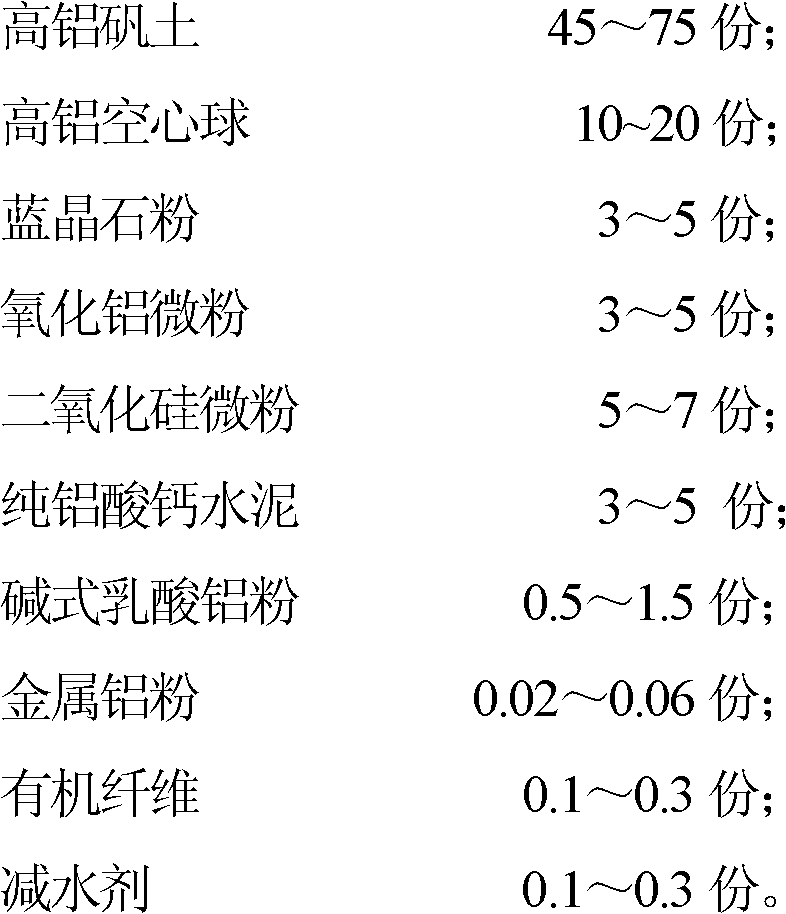

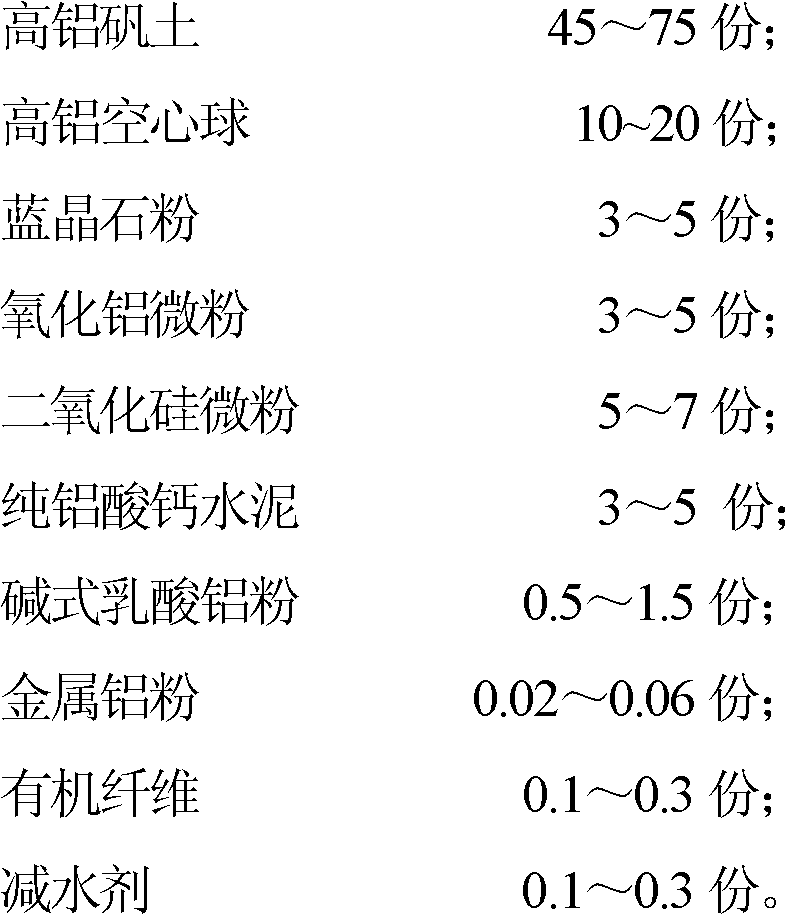

[0027] According to the content of the components described in Table 1, each raw material is weighed in turn, and the castable for the permanent layer of the ladle of the present invention can be prepared through forced kneading.

[0028] Various components involved in the present invention are common raw materials, which can be purchased conveniently in the chemical raw material market.

[0029] Table 1: Contents of each component in castables for ladles (unit: kg)

[0030]

[0031] α-alumina fine powder

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com