AM/NaAA/NAC water-soluble polymer oil-displacement agent and synthesizing method thereof

A technology of water-soluble polymer and oil-displacement agent, which is applied in the field of polymer oil-displacement agent and synthesis, to achieve the effects of enhanced oil recovery, increased viscosity, and enhanced rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: the preparation of NAC monomer

[0020] In a 250ml three-neck flask equipped with a reflux tube, dissolve 11.3g of caprolactam in tetrahydrofuran as a solvent, then add 3.0g of NaH, slowly add 13.5g of allyl bromide dropwise under constant stirring, and adjust the temperature to 10 o C, reaction 4h. Add a large amount of water under ice-cooling, extract with solvent dichloromethane, wash with saturated brine, dry and filter, and evaporate the solvent to obtain light yellow liquid NAC with a yield of 99%.

Embodiment 2

[0021] Example 2: Synthesis of AM / NaAA / NAC Terpolymer

[0022] First weigh acrylic acid and sodium hydroxide according to the ratio in Table 1, put them into a 250mL jar and dissolve them with distilled water, cool to room temperature, add AM and NAC, and dissolve them completely at room temperature, adjust the pH of the system with NaOH solution to approx. 8. Nitrogen for 20 minutes, add the pre-prepared sodium bisulfite solution, stir for 5 minutes, then add ammonium persulfate solution, continue nitrogen for 10 minutes, at a constant temperature of 45 oC Sealed and reacted for 12 hours; precipitated with absolute ethanol, crushed the precipitate into small particles, soaked in absolute ethanol for 2 days, 40 oC After drying for 2 days, the terpolymer AM / NaAA / NAC was obtained:

[0023] Table 1 Addition amount of ternary polymer synthetic drugs

[0024] drug Amount added (g) NAC 0.1530 distilled water 61.6000 AM 8.5300 AAA 4.3200 N...

Embodiment 3

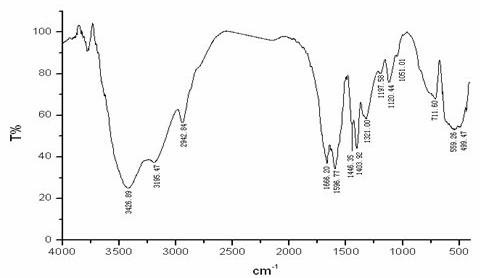

[0025] Embodiment 3: Structure characterization of AM / NaAA / NAC terpolymer

[0026] The infrared spectrogram of the terpolymer AM / NaAA / NAC synthesized by embodiment 2 is as follows figure 1 shown. It is known from the figure that N-H (-NH 2 ), C-N(-CH 2 -N-) The stretching vibration peaks are at 3426.89cm -1 and 1120.44cm -1 , the -C=O stretching vibration peak is at 1666.20cm -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com