Novel polypropylene composite

A technology of composite materials and polypropylene, which is applied in the field of polymer composite materials, can solve the problems of poor mixing of materials, poor interfacial wetting and adhesion, and inability to obtain composite materials with comprehensive properties, so as to reduce the use and reduce the The effect of consumption, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

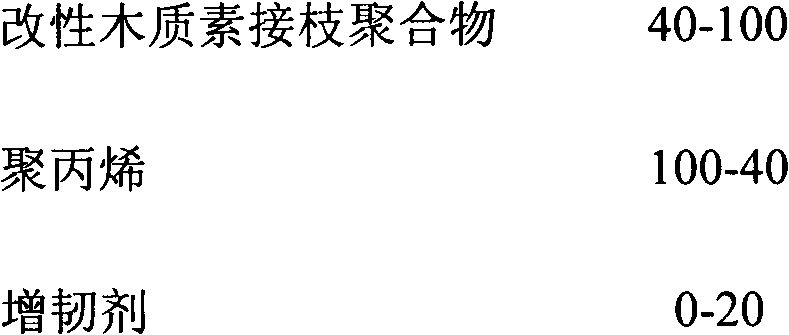

Method used

Image

Examples

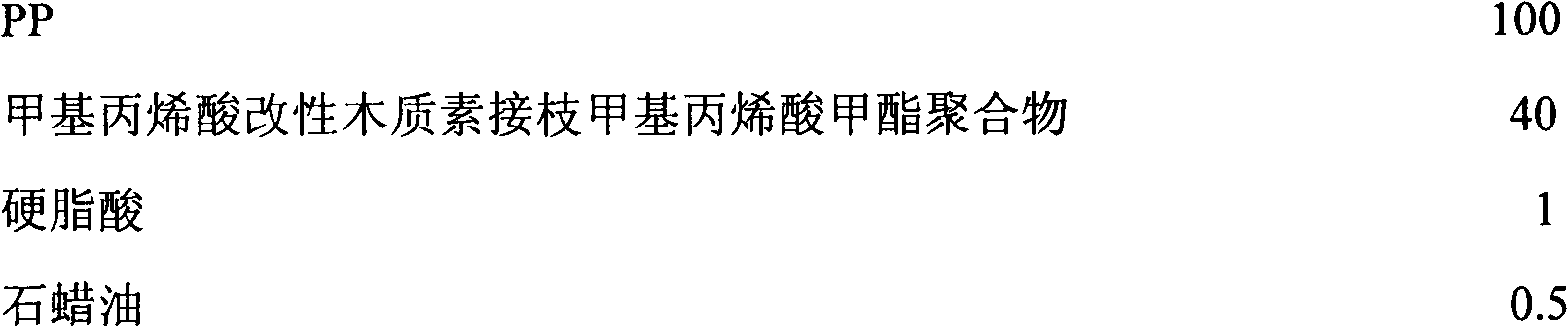

Embodiment 1

[0022] Embodiment 1: Methacrylic acid modified lignin grafted methyl methacrylate polymer / PP composite material

[0023] Step 1: Put 100g of purified sodium lignosulfonate and 25g of methacrylic acid in a stainless steel airtight tank, mix evenly, place in an oil bath to heat up, react at 160-170°C for 7-10min, and take out the product after cooling , soaked in acetone for 24 hours, washed twice with acetone to remove unreacted methacrylic acid, and dried in an oven at 60°C to obtain methacrylic acid-modified lignin. Weigh 30g of methacrylic acid-modified lignin and 0.5g of dibenzoyl peroxide into a polymerization bottle, and perform vacuum pumping and nitrogen filling operations to remove the air in the bottle. Measure 100ml of ethyl acetate, stir well to dissolve the solid, then add 120ml of methyl methacrylate into the polymerization bottle with a syringe, shake well, and react at 80°C for 3 hours to end the reaction. Finally, pour the polymerization solution into a beaker...

Embodiment 2

[0027] Embodiment 2: Methacrylic acid modified lignin grafted styrene polymer / PP composite material

[0028] Step 1: Put 100g of purified sodium lignosulfonate and 20g of methacrylic acid in a stainless steel sealed tank, mix them evenly, put them in an oil bath to heat up, react at a certain temperature for a certain period of time, take out the product after cooling, and use acetone After soaking for 24 hours, it was washed twice with acetone to remove unreacted methacrylic acid, and dried in an oven at 60°C to obtain methacrylic acid-modified lignin. Weigh 30g of methacrylic acid-modified lignin and 0.5g of dibenzoyl peroxide into a polymerization bottle, and perform vacuum pumping and nitrogen filling operations to remove the air in the bottle. Measure 100ml of ethyl acetate, stir well to dissolve the solid, then add 150ml of styrene into the polymerization bottle with a syringe, shake well, and react at 80°C for 3h to end the reaction. Finally, pour the polymerization so...

Embodiment 3

[0031] Embodiment 3: methacrylic acid modified lignin grafted styrene polymer / PP composite material (add toughening agent POE-g-GMA)

[0032]Step 1: Put 100g of purified sodium lignosulfonate and 20g of methacrylic acid in a sealed stainless steel tank, mix them evenly, put them in an oil bath to heat up, react at a certain temperature for a certain period of time, take out the product after cooling, and use acetone After soaking for 24 hours, it was washed twice with acetone to remove unreacted methacrylic acid, and dried in an oven at 60°C to obtain methacrylic acid-modified lignin. Weigh 30g of methacrylic acid-modified lignin and 0.5g of dibenzoyl peroxide into a polymerization bottle, and perform vacuum pumping and nitrogen filling operations to remove the air in the bottle. Measure 100ml of ethyl acetate, stir well to dissolve the solid, then add 150ml of styrene into the polymerization bottle with a syringe, shake well, react at 80°C for 3h, and then end the reaction. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com