Fluorine-containing composition, and membrane thereof

A composition and polymer technology, applied in the field of fluorine-containing polymers, can solve problems such as limitation, reduction of resin yield and accumulation, achieve excellent alkali resistance and processing performance, increase resin yield, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

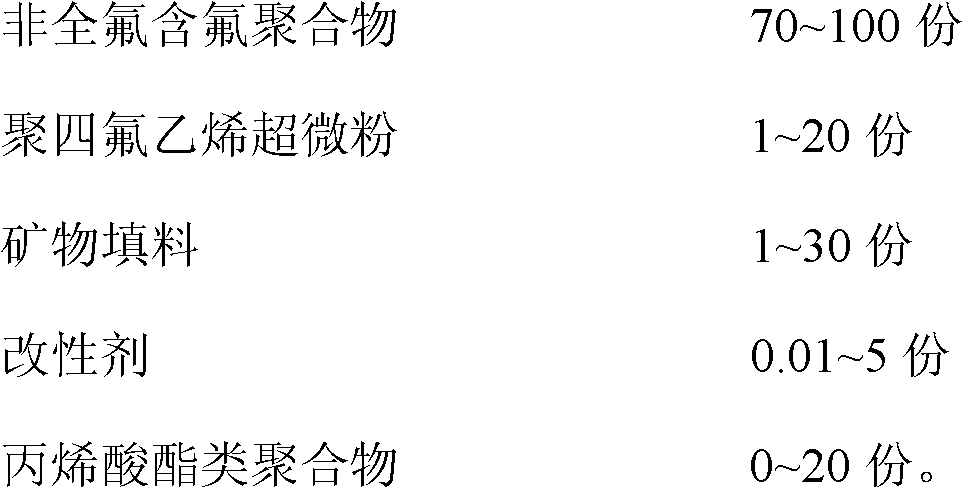

Method used

Image

Examples

Embodiment 1

[0019] 70 parts of polyvinylidene fluoride homopolymer powder, 1 part of polytetrafluoroethylene superfine powder with a weight average molecular weight of 5000 and an average particle diameter of 0.01 μm, 1 part of titanium dioxide, 0.01 part of isopropyl tri(dioctyl pyrophosphate Acyloxy) titanate coupling agent, after high-speed mixing, thermoplastic processing and granulation at 200-220 ° C, and then extruded into a film with an average thickness of 5 μm through an extruder at 210-230 ° C, and rolled. During the processing, there is no bonding at the die mouth, no accumulation of material, and a high film forming rate.

Embodiment 2

[0021] 100 parts of vinylidene fluoride-hexafluoropropylene copolymer powder, 20 parts of polytetrafluoroethylene superfine powder with a weight average molecular weight of 200,000 and an average particle diameter of 20 μm, 30 parts of silicon dioxide, and 5 parts of γ-aminopropyltriethyl Oxysilane coupling agent, after high-speed mixing, it is granulated by thermoplastic processing at 180-210 ° C, and then extruded by an extruder at 200-230 ° C to form a film with an average thickness of 10 μm, and it is wound. During the processing, there is no bonding at the die mouth, no accumulation of material, and a high film forming rate.

Embodiment 3

[0023] 90 parts of polyvinyl fluoride copolymer powder, 10 parts of polytetrafluoroethylene superfine powder with a weight average molecular weight of 100000 and an average particle diameter of 10 μm, 15 parts of calcium carbonate, 2 parts of isopropoxy aluminate, 10 parts of methyl acrylate Ester-methyl methacrylate copolymer, after high-speed mixing, heat-plasticized at 180-210°C for granulation, then extruded by extruder at 200-230°C to form a film with an average thickness of 50 μm, and rolled. During the processing, there is no bonding at the die mouth, no accumulation of material, and a high film forming rate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com