Preparation method for abelmoschus esculentus proteoglycan protein xerium

A technology for polysaccharide protein and dry powder, which is applied in the field of preparation of okra polysaccharide protein dry powder, can solve the problems of few functional foods, uneven quality and other problems, and achieves the effects of reducing extraction cost, increasing yield and reducing enzyme price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

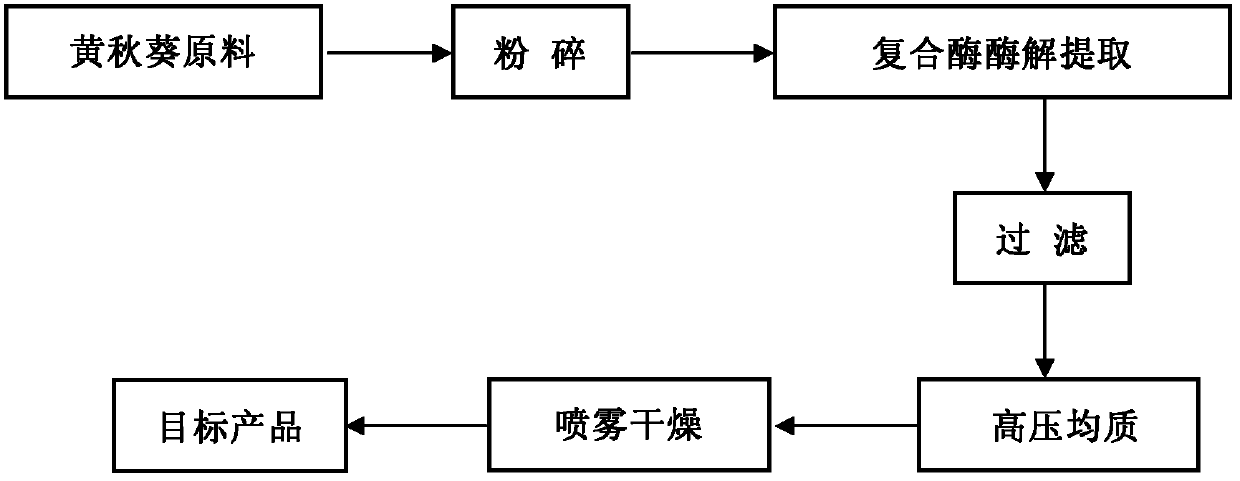

Method used

Image

Examples

Embodiment 1

[0050] Take 1000g of fresh okra fruit, add 10-20L of water, pulverize with a tissue grinder, add a compound enzyme for enzymatic hydrolysis and extraction (the compound enzyme is composed of cellulase, helicase, and lysozyme, and the mass ratio of the three is 6:2:1), The amount of enzyme added is 0.5wt%-2.5wt% of the dry weight of the okra. The enzymolysis extraction conditions are as follows: pH=6.5-7.5, temperature 32-40°C, power 600-800W, ultrasonic working time 2-5s, intermittent time 1-3s, extraction time 6-7h. After the extraction is completed, the large particle residue is removed by centrifugation, and then suction-filtered to obtain the okra polysaccharide protein extract.

[0051] Add maltodextrin to the okra polysaccharide protein extract prepared above, the amount of maltodextrin added is 1 to 35% by weight of the dry matter of the okra polysaccharide protein extract, and after the maltodextrin is added, carry out high-pressure homogenization, and the homogenizati...

Embodiment 2

[0053] Take 1000g of fresh okra fruit, add 15-20L of water, grind it with a tissue grinder, add compound enzyme to extract (the compound enzyme is composed of cellulase, helicase, and lysozyme, and the mass ratio of the three is 6.5:2.3:1), add enzyme The amount is 0.5wt% to 3wt% of the dry weight of the okra. The enzymolysis extraction conditions are as follows: pH=6.5-7.2, temperature 30-38°C, power 650-800W, ultrasonic working time 2-4s, intermittent time 1-2s, extraction time 7-8h. After the extraction is completed, the large particle residue is removed by centrifugation, and then suction-filtered to obtain the okra polysaccharide protein extract.

[0054] Add maltodextrin to the okra polysaccharide protein extract obtained above, the amount of maltodextrin added is 1 to 45 wt% of the dry matter of the okra polysaccharide protein extract, and after the maltodextrin is added, carry out high-pressure homogenization, and the homogenization pressure is 20-45 wt%. 25MP, homoge...

Embodiment 3

[0056]Take 1000g of quick-frozen fresh okra fruit, add 15-25L of water, pulverize with a tissue grinder, and extract with a compound enzyme (the compound enzyme is composed of cellulase, helicase, and lysozyme, and the mass ratio of the three is 6.3:2.2:1), add The enzyme amount is 1.0wt%-2.3wt% of the dry weight of the okra. The enzymolysis extraction conditions are as follows: pH=6.8-7.5, temperature 32-39°C, power 600-780W, ultrasonic working time 3-5s, intermittent time 2-3s, extraction time 6.5-8h. After the extraction is completed, the large particle residue is removed by centrifugation, and then suction-filtered to obtain the okra polysaccharide protein extract.

[0057] Add maltodextrin to the okra polysaccharide protein extract obtained above, the amount of maltodextrin added is 1-40wt% of the dry matter of the okra polysaccharide extract, after the maltodextrin is added, perform high-pressure homogenization, and the homogenization pressure is 16-20MP , homogeneous c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com