Glass mixing powder, preparation method thereof and conductive silver paste containing glass mixing powder

A technology of conductive silver paste and glass powder, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problem of low photoelectric conversion efficiency and electrode peeling strength, unfavorable electrode and silicon ohmic contact, and narrow glass powder sintering process window and other issues, to achieve the effect of improving photoelectric conversion efficiency, good ohmic contact, and reducing series resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

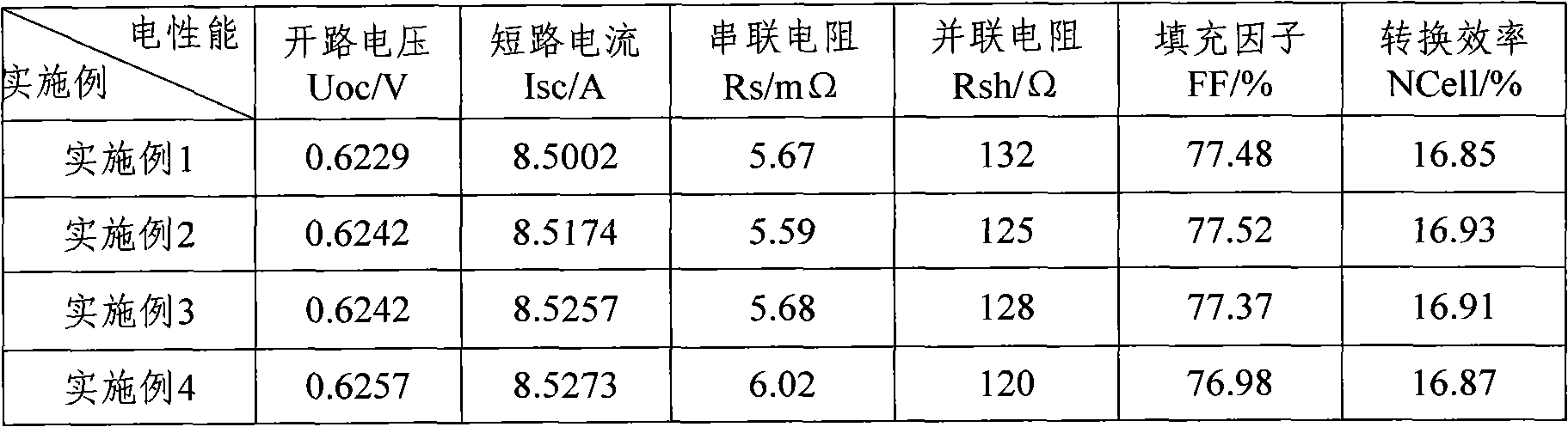

Examples

Embodiment 1

[0020] A glass mixed powder, the glass mixed powder contains 35wt% of glass powder A and 65wt% of glass powder B, and the softening point of glass powder A is lower than that of glass powder B.

[0021] Wherein, one of glass powder A and glass powder B is lead-free glass powder.

[0022] Wherein, glass powder A is leaded glass powder, and the composition of glass powder A comprises: the PbO of 60wt%, the SiO of 20wt% 2 , 10wt% B 2 o 3 , 7wt% of ZnO and 3wt% of MgO.

[0023] Wherein, the composition of glass powder B includes: 50wt% Bi 2 o 3 , 20wt% SiO 2 , 10wt% ZnO, 15wt% B 2 o 3 , 3wt% TiO 2 and 2wt% Al 2 o 3 .

[0024] Wherein, the particle size of the glass powder A and the glass powder B are both less than 5 μm.

[0025] A kind of preparation method of glass mixed powder, preparation method comprises the following steps:

[0026] The first step: configure raw glass powder according to the ratio described in claim 1;

[0027] Step 2: Put the prepared glass po...

Embodiment 2

[0037] A glass mixed powder, the glass mixed powder contains 40wt% of glass powder A and 60wt% of glass powder B, and the softening point of glass powder A is lower than that of glass powder B.

[0038] Wherein, one of glass powder A and glass powder B is lead-free glass powder.

[0039] Wherein, glass powder A is leaded glass powder, and the composition of glass powder A comprises: the PbO of 65wt%, the SiO of 15wt% 2 , 8wt% B 2 o 3 , 10wt% ZnO and 2wt% MgO.

[0040] Wherein, the composition of glass powder B includes: 60wt% Bi 2 o3 , 15wt% SiO 2 , 8wt% ZnO, 12wt% B 2 o 3 , 1wt% TiO 2 and 4wt% Al 2 o 3 .

[0041] Wherein, the particle size of the glass powder A and the glass powder B are both less than 5 μm.

[0042] A kind of preparation method of glass mixed powder, preparation method comprises the following steps:

[0043] The first step: configure the raw glass powder according to the above ratio;

[0044] Step 2: Put the prepared glass powder into the mixing...

Embodiment 3

[0052] A glass mixed powder, the glass mixed powder comprises 50wt% of glass powder A and 50wt% of glass powder B, and the softening point of glass powder A is lower than that of glass powder B.

[0053] Wherein, glass powder B is lead-free glass powder.

[0054] Wherein, glass powder A is leaded glass powder, and the composition of glass powder A comprises: the PbO of 75wt%, the SiO of 10wt% 2 , 6wt% B 2 o 3 , 8 wt% of ZnO and 1 wt% of MgO.

[0055] Wherein, the composition of glass powder B includes: 70wt% Bi 2 o 3 , 10wt% SiO 2 , 6wt% ZnO, 9wt% B 2 o 3 , 2wt% TiO 2 and 3wt% Al 2 o 3 .

[0056] Wherein, the particle size of the glass powder A and the glass powder B are both less than 5 μm.

[0057] A kind of preparation method of glass mixed powder, preparation method comprises the following steps:

[0058] The first step: configure the raw glass powder according to the above ratio;

[0059] Step 2: Put the prepared glass powder into the mixing equipment and mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com