Natural pullulan polysaccharide hydrogel wound dressing and preparation method thereof

A technology of pullulan and carboxymethylated pullulan, which is applied in the field of polymer biomedical materials, can solve the problems of complex synthesis process, inability to satisfy dressings, poor swelling performance, etc., and achieves simple operation, easy access, The effect of preventing dehydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

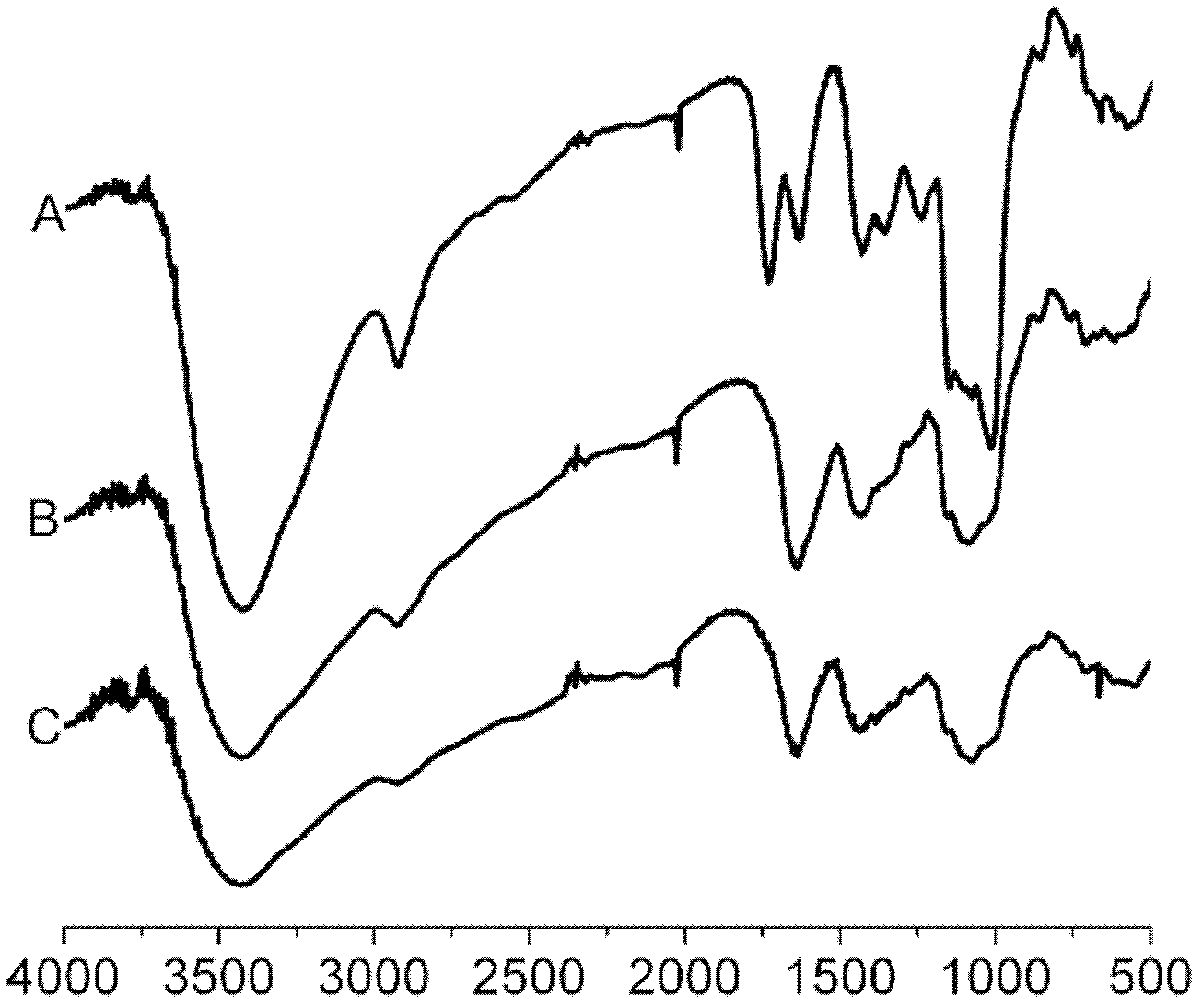

Image

Examples

Embodiment 1

[0038] The processing steps of the present embodiment are as follows:

[0039] (1) Add isopropanol to the natural pullulan aqueous solution, then add sodium hydroxide aqueous solution, stir at normal pressure and 50°C until a transparent solution is formed; the natural pullulan aqueous solution is prepared with deionized water , the concentration is 0.1g / ml, the volume ratio of the isopropanol to the natural pullulan aqueous solution is 1:7 / 3; the sodium hydroxide aqueous solution is prepared with deionized water, the concentration is 0.1g / ml, and the hydrogenation The amount of sodium aqueous solution is limited with the mol ratio=1:1 of the glucose unit of natural pullulan polysaccharide in the mixed solution and sodium hydroxide;

[0040] (2) sodium chloroacetate aqueous solution and isopropanol are joined in the mixed solution prepared by step (1) simultaneously, under normal pressure, 50 ℃ of reaction 2 hours under stirring; The concentration of described sodium chloroaceta...

Embodiment 2

[0048] The processing steps of the present embodiment are as follows:

[0049] (1) Add isopropanol to the natural pullulan aqueous solution, then add sodium hydroxide aqueous solution, stir at normal pressure and 70°C until a transparent solution is formed; the natural pullulan aqueous solution is prepared with deionized water , the concentration is 0.25g / ml, the volume ratio of the isopropanol to the natural pullulan aqueous solution is 1:10; the sodium hydroxide aqueous solution is prepared with deionized water, the concentration is 0.2g / ml, the sodium hydroxide aqueous solution The amount is limited with the mol ratio=1:1.2 of the glucose unit of natural pullulan polysaccharide and sodium hydroxide in the mixed solution;

[0050] (2) sodium chloroacetate aqueous solution and isopropanol are joined in the mixed solution prepared by step (1) simultaneously, under normal pressure, 70 ℃ of reaction 3 hours under stirring; The concentration of described sodium chloroacetate aque...

Embodiment 3

[0058] The processing steps of the present embodiment are as follows:

[0059] (1) Add isopropanol to the natural pullulan aqueous solution, then add sodium hydroxide aqueous solution, stir at normal pressure and 50°C until a transparent solution is formed; the natural pullulan aqueous solution is prepared with deionized water , the concentration is 0.3g / ml, the volume ratio of the isopropanol to the natural pullulan aqueous solution is 1:9; the sodium hydroxide aqueous solution is prepared with deionized water, the concentration is 0.3g / ml, the sodium hydroxide aqueous solution The amount is limited with the mol ratio=1:1.3 of the glucose unit of natural pullulan polysaccharide and sodium hydroxide in the mixed solution;

[0060] (2) sodium chloroacetate aqueous solution and isopropanol are joined in the mixed solution prepared by step (1) simultaneously, under normal pressure, 50 ℃ of reaction 4 hours under stirring; The concentration of described sodium chloroacetate aqueou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com